Clarus Environmental Standard Riser Systems User Manual

Standard riser system installation instructions

SECTION: C5.20.130

CL0105

0512

Supersedes

New

3649 Cane Run Road . Louisville, KY 40211-1961

877-244-9340 . Fax: 877-414-4316

www.clarusenvironmental.com

Standard Riser System

INSTALLATION INSTRUCTIONS

NOTICE TO INSTallEr: Instructions must remain with installation.

© Copyright 2012. All rights reserved.

1. Unpack risers and accessories and examine for any damage that may have occurred during shipping.

2. You may adjust the height on all risers by cutting the top of the riser between any two ribs. The bottom of the riser must remain flat

to ensure maximum surface area for adhesive.

3. All covers require a Robertson square head driver for removal.

SK2294B

FIG. 1

Bolt Down Kit (See FIG. 1):

1. Clean and dry the mounting surface on both the riser and

the septic tank. Wash the top of the tank with detergent

and water. Clean the riser's flat bottom flange with PVC

cleaner or lacquer thinner to provide the best seal.

2. Apply a ½” bead of sealant to the riser's flat bottom flange.

3. Carefully align the riser over the hole in the tank and place

the riser down on tank.

4. Drill four 3/8” holes 90 degrees apart. Locate the holes as

close as possible to the riser (1/4” max.). Drill the holes

at a slight angle to ensure getting as close as possible to

the riser. Drill the hole deep enough to allow 1” of stud to

be above the concrete. Example: if the stud is 2-3/8” long,

drill the hole 1-3/8” deep.

5. Place the large fender washer on first, then the standard

washer, followed by the nut, and tighten.

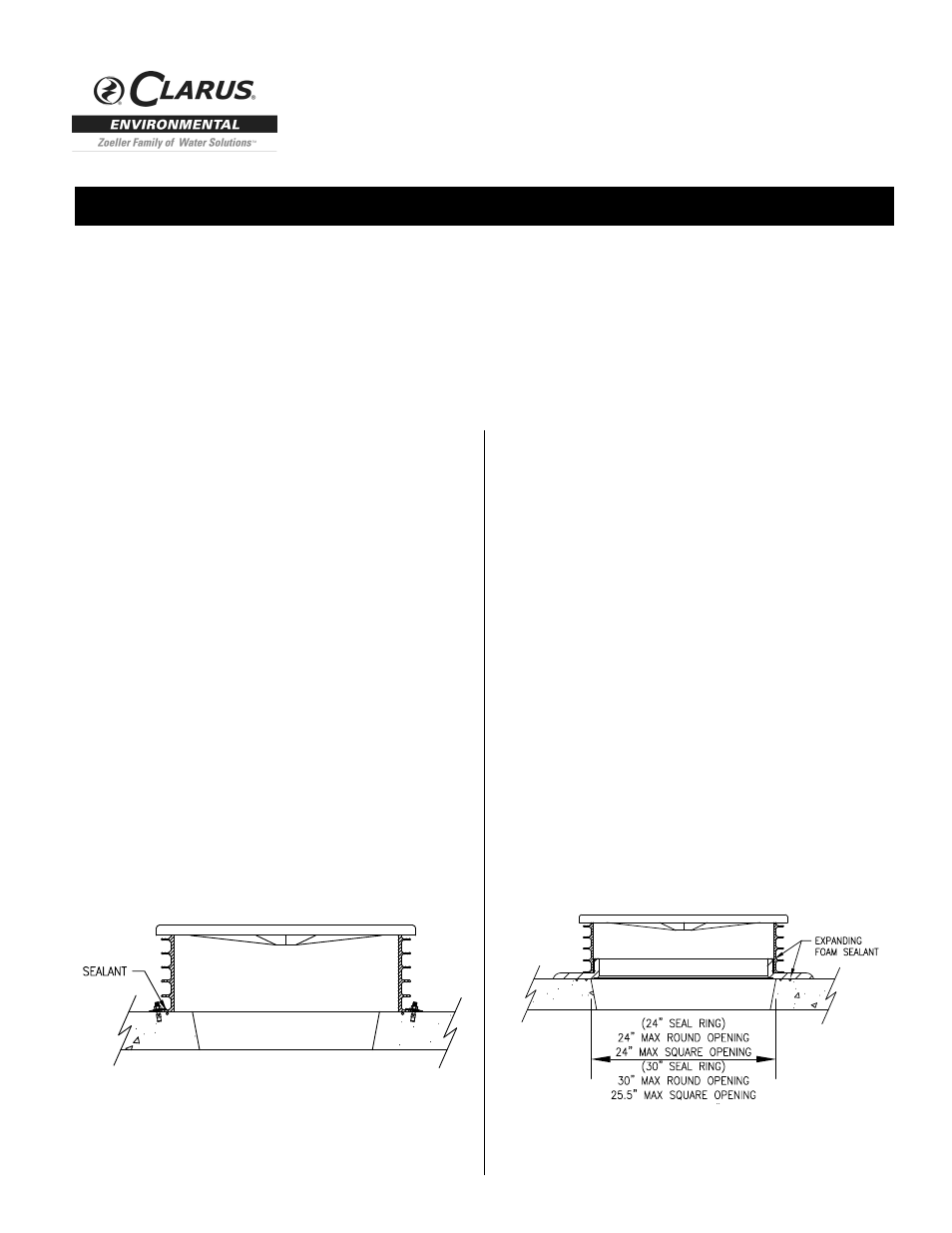

Seal Ring (See FIG. 2):

1. Clean and dry the mounting surface on both the riser

ring and the septic tank. Wash the top of the tank with

detergent and water. Clean the seal ring and riser with

PVC cleaner or lacquer thinner to provide the best seal.

2. Position the seal ring on the septic tank, lining up the hole

in the top of the tank with the hole in the mounting flange.

Draw a line around the outside of the ring on the tank.

3. Remove the ring and apply foam in the area where the

ring will be set. Apply a 2” bead of foam on the tank or two

1” beads, depending on how much area you have to set

the ring.

4. Position the seal ring back on the tank and apply moderate

to firm pressure.

5. Apply a 2” bead of foam at the base of the ring where the

riser will sit.

6. Set the riser on the seal ring. Note: On short sections of

riser, reach inside the riser and fill any voids between the

riser and the seal ring. On long sections of riser, apply a

second bead of foam to the inside vertical section of the

seal ring before installing the riser. This will ensure there

are no voids between the seal ring and the riser.

7. Wait a minimum of one hour and backfill. Be careful not to

damage the riser.

FIG. 2

SK2294C

Does not apply to 18" dia. riser.