Installing clamps, Installing band-it center punch clamps – BAND-IT SM1700 Pneumatic Center Punch Tool User Manual

Page 6

Document# SM1750 Rev. E

© Copyright

BAND-IT-IDEX, Inc. 2012

All rights reserved

www.BAND-IT-IDEX.com

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver, CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

6

SM1700

Pneumatic

Center Punch

Tool

Installing BAND-IT Center Punch Clamps:

1)

Choose correct material type and diameter clamp to best satisfy the needs of the application.

2)

Installation of two BAND-IT Center Punch Clamps per hose end is suggested. Place clamps over hose, then

install fitting. Note the location of the fitting’s hose barbs in order to locate clamps between barbs for maximum

fitting retention. The buckles of each clamp should be located opposite of each other to increase resistance to

leak paths.

3)

Insert the clamp tail fully into the nose of the tool with the buckle on top. Position the clamp in the desired

location on hose.

4)

Small diameter hose assemblies (less than approximately 2”) will receive a considerable impact during the lock

and clamp tail cut-off process. For stiff hoses, it will help to lessen the impact by holding these small hose

assemblies with only one hand on the hose end of the assembly (do not hold the end of the assembly with the

fitting). This will soften the jolt and allow the assembly to swing down to absorb the impact. For flat or thin-wall

hose, inserting an object that is soft and safe to hold into the end of the fitting for additional support may help.

Large diameter hose assemblies should be held securely with both hands.

Keep hands away from clamp being applied!

5)

Depress the toe end of the foot pedal control to tension clamp, keep the toe end down until the clamp has been

fully tensioned, locked and cut-off is complete.

6)

If the cylinder reaches the end of its stroke during tension, the cutoff cylinder will be disabled and the end-of-

stroke indicator will turn red. Pull firmly on the clamp while reversing the cylinder. Remove the clamp. Before

regripping, cut off any tail greater than 4 inches. Start the tension cycle over at step 3.

7)

Depress the heel end of the foot control and retrieve the clamp tail from the tool head.

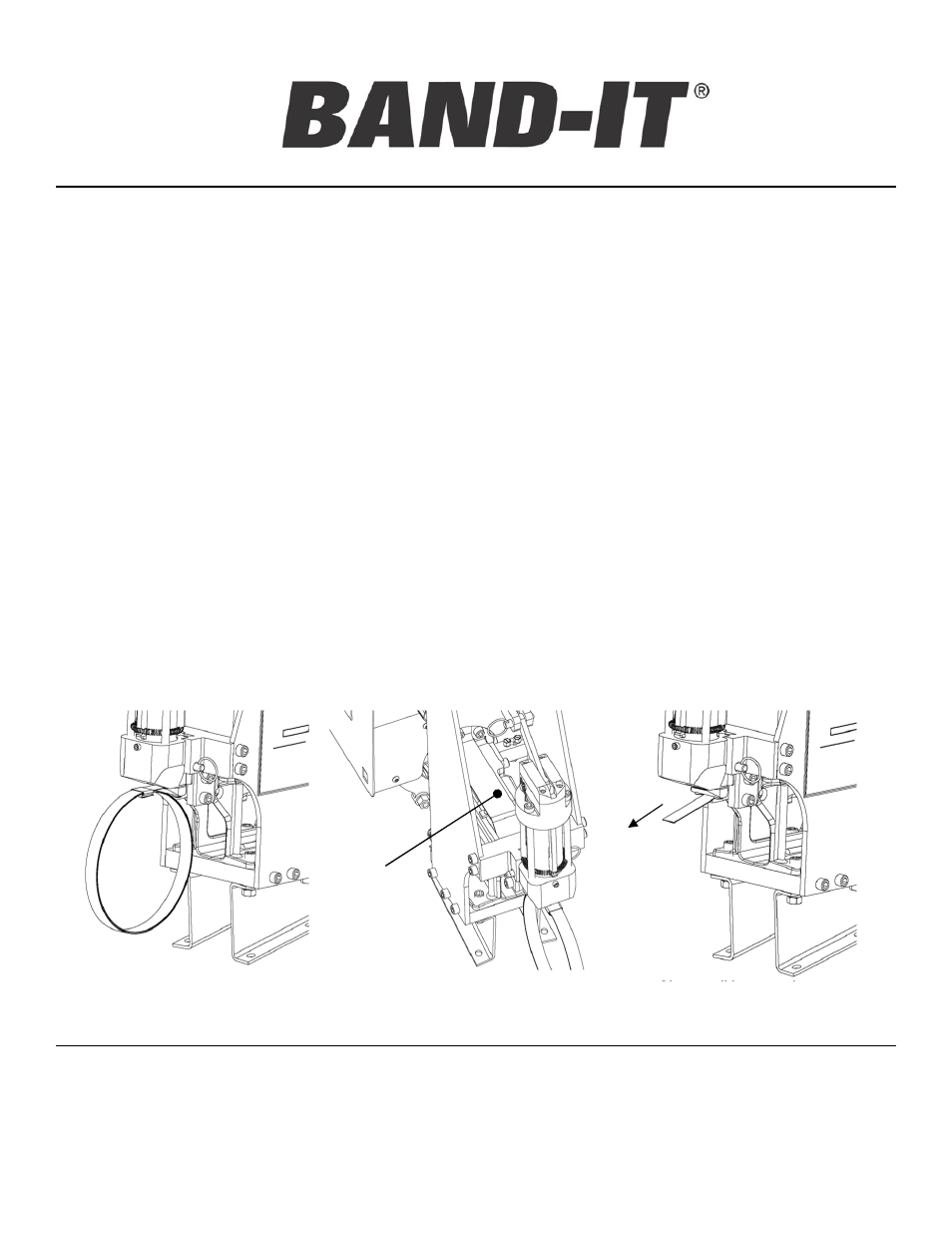

Clamp tail inserted into blade

assembly

Guard/tail depressor provides downward

pressure on scrap clamp tail.

Clamp tail in normal return

position. Pull tail from tool.

Installing

Clamps