Setting controls and tool operation – BAND-IT S75099 Pneumatic Junior Clamp Application Tool User Manual

Page 7

Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925

7

S75099 Pneumatic

Junior Clamp

Application Tool

Rule:

Always approach the pull-up pressure setting from below and the holding

pressure setting from above the recommended value.

Rule:

Gauge readings are to be used as a guide. It may be necessary to adjust the

Pull-Up and Holding Pressure settings to match the requirements of the

particular hose assembly construction or application.

1. Speed Control adjusts the speed of piston travel during tensioning of the band clamp. A

slower setting will allow more time while a faster setting may cause increased friction

between the band and the buckle as the clamp tail is pulled through the buckle during

tensioning. Increased friction may cause the clamp to tension improperly.

2. Setting the Speed Control: The speed of the cycle should be set according to the width

of Junior Clamp being tensioned. Each width clamp has a color code setting on the

speed control regulator. See this manual page # 8 or the decal on the side of the tool.

Use the attached lock ring to secure the desired setting and prevent accidental

changes.

3. Pull-up Pressure reflects the tension applied to the clamp and is measured by force

applied to the clamp tail being pulled through the buckle. A pull-up pressure setting too

low may allow the fitting to be forced out of the hose assembly. A setting too high may

cause damage to the assembly or cause the clamp tail to tear. For most hose

applications, the ideal setting is as high as can be achieved without sacrificing the

strength of the lock, damaging the hose and fitting or breaking the clamp tail.

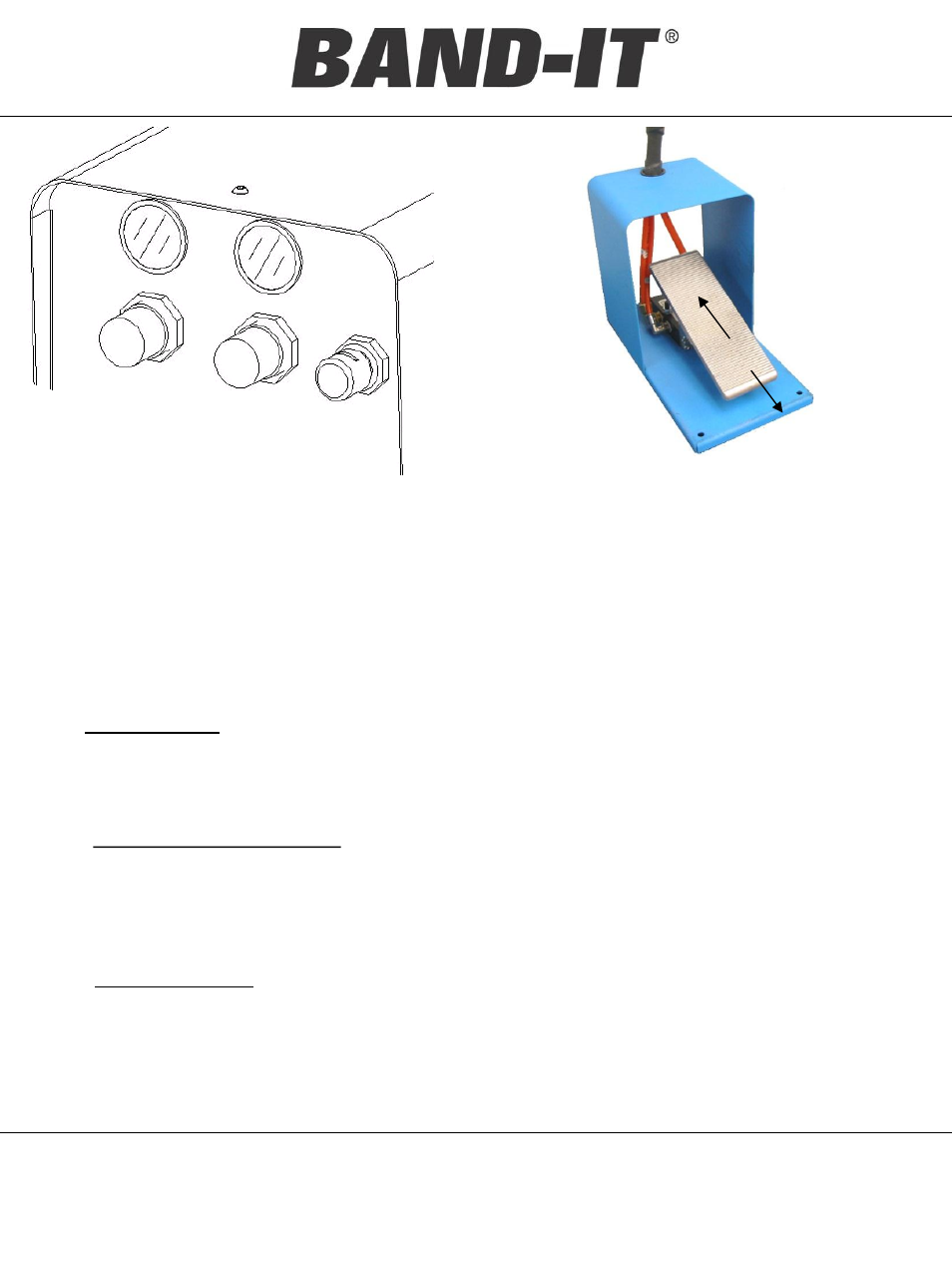

Dual function foot control valve. Pressing forward

activates clamp installation. Heel action activates tail

return and prepares for next clamp.

Air pressure setting can be made using the regulators

and gauges on face of the tool.

Setting Controls

and Tool

Operation