Troubleshooting – BAND-IT S35099 Automatic Air Tool User Manual

Page 20

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

www.BAND-IT-IDEX.com

Page 20 of 34

S35099

Automatic Air Tool

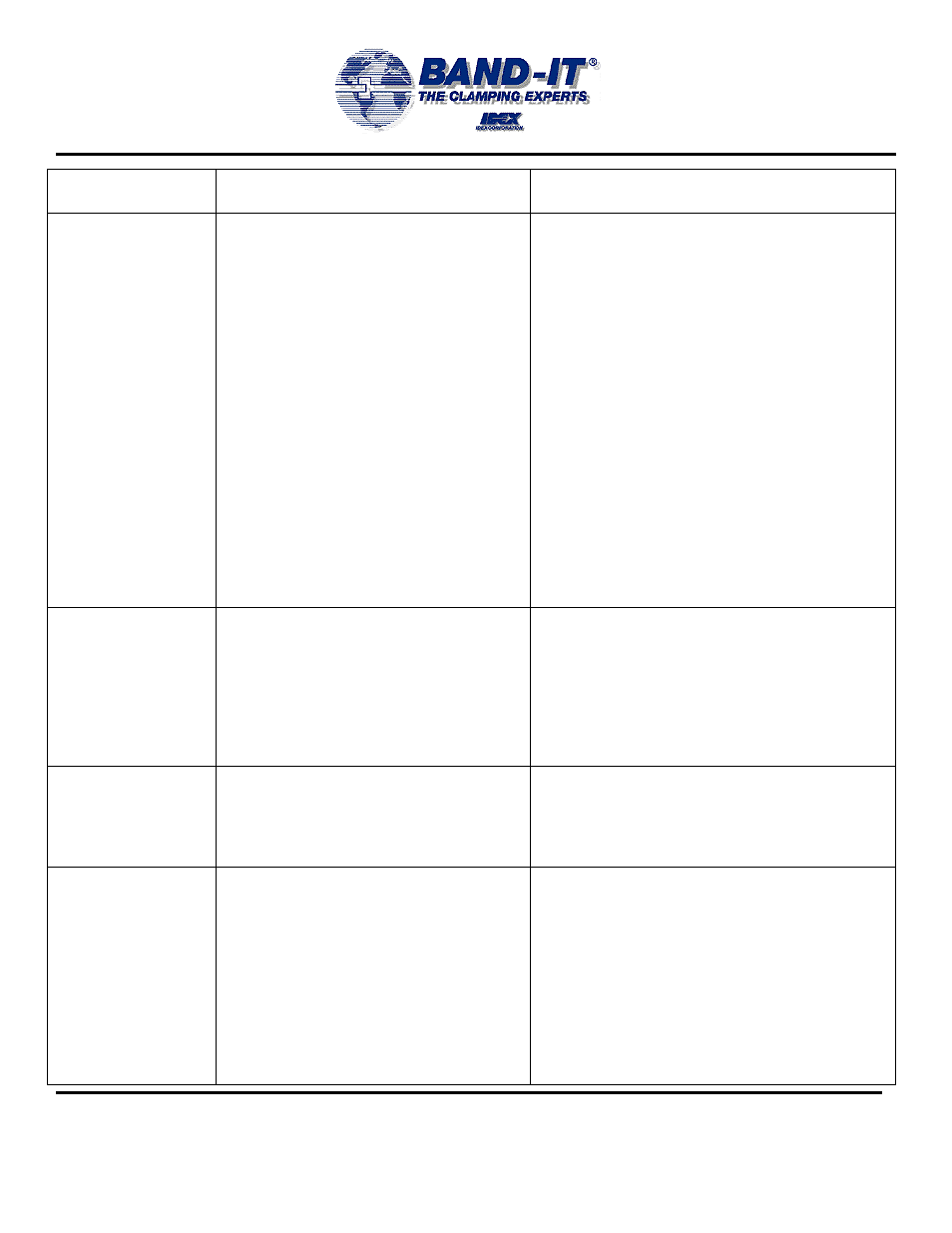

PROBLEM

OBSERVATION

CORRECTION

9) Tool doesn’t cut

off clamp.

- Cut-off cylinder stalls and does not

cut off clamp tail.

- Clamp tail bends and allows tool to

force buckle past cutter blade edge.

- Check for loose or broken cutter blade.

Tighten screws if loose. Replace cutter

blade if broken.

- Reset clamp hold pressure to recommended

pressure.

- If air line supply pressure is below 100 PSI,

stop operation and correct or allow pressure

to rise above 100 PSI.

- Check cut-off cylinder air cushion valve (fig.

14). It might be screwed in too deep.

- Cut-off cylinder piston seals leak. Loosen

nut off of tube Q. If air is still escaping

remove cylinder and replace seals.

- Cut-off cylinder piston rod may be binding.

Shut off air supply and remove tubes B and

Q and operate piston rod by hand to see if it

moves freely. If not, check back-up roller for

.010” clearance or remove cylinder.

- Lubricate between shear hook and cut-off

cam.

10) Tool never

reaches the

selected pull

pressure. Tool

operation may

be erratic in this

portion of the

cycle.

- Pressure observed increases, then

drops rapidly and jumps back up to a

higher pressure.

- Tool cycles to start the clamp holding

cycle before selected pressure is

observed on gauge.

- Increase the clamp pull cycle time to allow

the tool to regulate to the selected pressure.

- Air line pressure may be lower than the

selected pressure. Check and correct.

- Check the system for an air leak.

11) Tool takes

excessive time

for clamp pull-

up.

- Tool pulls the clamp and reaches the

selected holding pressure, then the

operator waits before the tool

operates to the holding and cut-off

cycle.

- Decrease the clamp pull cycle time (fig. 4).

12) Tool does not

tighten clamps

- Selection of higher clamp pull

pressure does not result in tighter

clamps. Excessive amount of air is

exhausting from the quick-exhaust

valve.

- Check for air system leak. Tighten or

replace defective items.

- Pull cylinder seal may be leaking. Operate

tool to stall the cylinder. Remove tube N and

if air is escaping, disassemble pull cylinder

and repair.

- Check to see if gripper level pin is dragging

on the base. Reposition and retighten the

set screw that retains the pin (fig 6).

Troubleshooting