Operating instructions – BAND-IT S35099 Automatic Air Tool User Manual

Page 14

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # S41067 rev. H

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

www.BAND-IT-IDEX.com

Page 14 of 34

S35099

Automatic Air Tool

APPLYING CLAMPS

The following step-by-step instructions should be followed to successfully tension and lock a clamp.

This information is also summarized on a decal located on the lower left front panel and explained in

further detail in other sections of this manual.

CAUTION!

When operating, do not place fingers near or between the clamp band and the item being

clamped as they could be pinched.

1. Set and/or check clamp pull pressure.

2. Slide clamp over object being clamped. Insert tail of clamp into the open slot of the backing

plate of the clamp tool head. Push the clamp tail into the head as far as possible (the clamp

buckle should be almost touching the backing plate of the clamp tool head).

3. Support the item being clamped. The operator should hold the object so the clamp buckle is

essentially level with the tail and should also keep the object horizontal and lift it if necessary

as the weight of the assembly is not held by the clamp.

4. Depress the pedal of the foot control valve and hold the pedal down as the tool operates

through its cycle.

5. Allow the tool to tighten the clamp and observe the pull pressure. The tool will then

automatically cycle and lower the pressure in the pull cylinder to the hold pressure.

6. Roll up hose when clamp hold gauge drops to approximate roll up pressure shown in chart

below. Rotate object being clamped upward and position clamp buckle under shear hook of

machine.

7. Support the object being clamped as the cut-off cylinder automatically pushes the cam outward

to perform and cut-off operation.

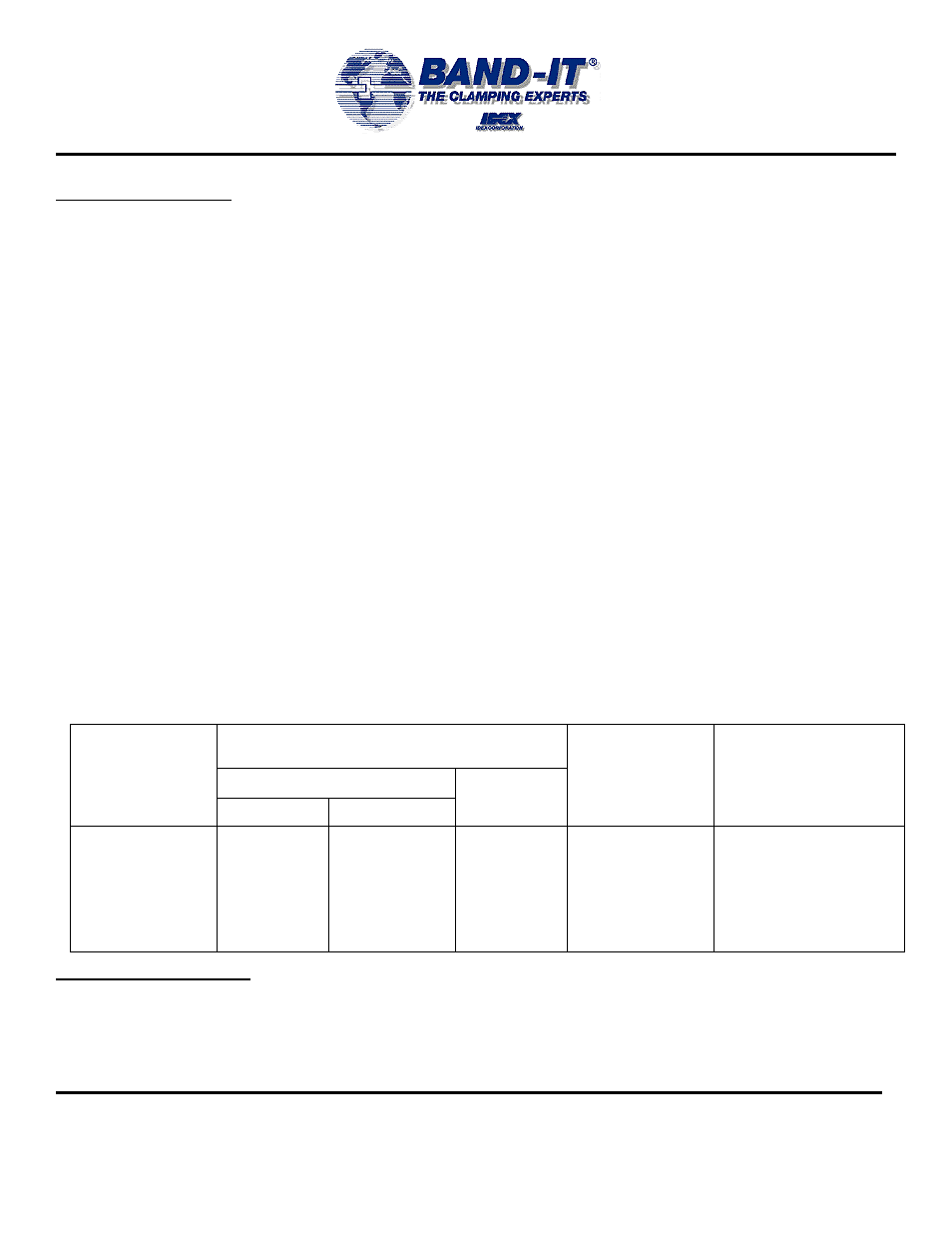

Clamp Width

(mm)

Pull-Up Pressure

(psi)

Hold Pressure

(psi)

Roll Up Pressure

(psi)

Stainless Steel

Carbon

Steel

201 SS

316 SS

1/4" (6.35)

3/8" (9.525)

1/2" (12.7)

5/8" (15.875)

3/4" (19.05)

15

25

40

50

60

15

20

35

40

50

-

25

40

50

60

6-7

6-7

8-9

9-10

10-12

9-10

9-10

11-12

12-14

13-16

STOPPING THE TOOL

Should the occasion arise that the tool operation must be stopped to clear a jammed clamp, the tool

cycle can be stopped by releasing the foot control valve and the tool will reset itself. Should the

control valve again be depressed prior to allowing the tool to reset, erratic cycling will result.

Operating

Instructions