Anchor ANCHORSPAN A 60FT-80FT User Manual

Page 18

14

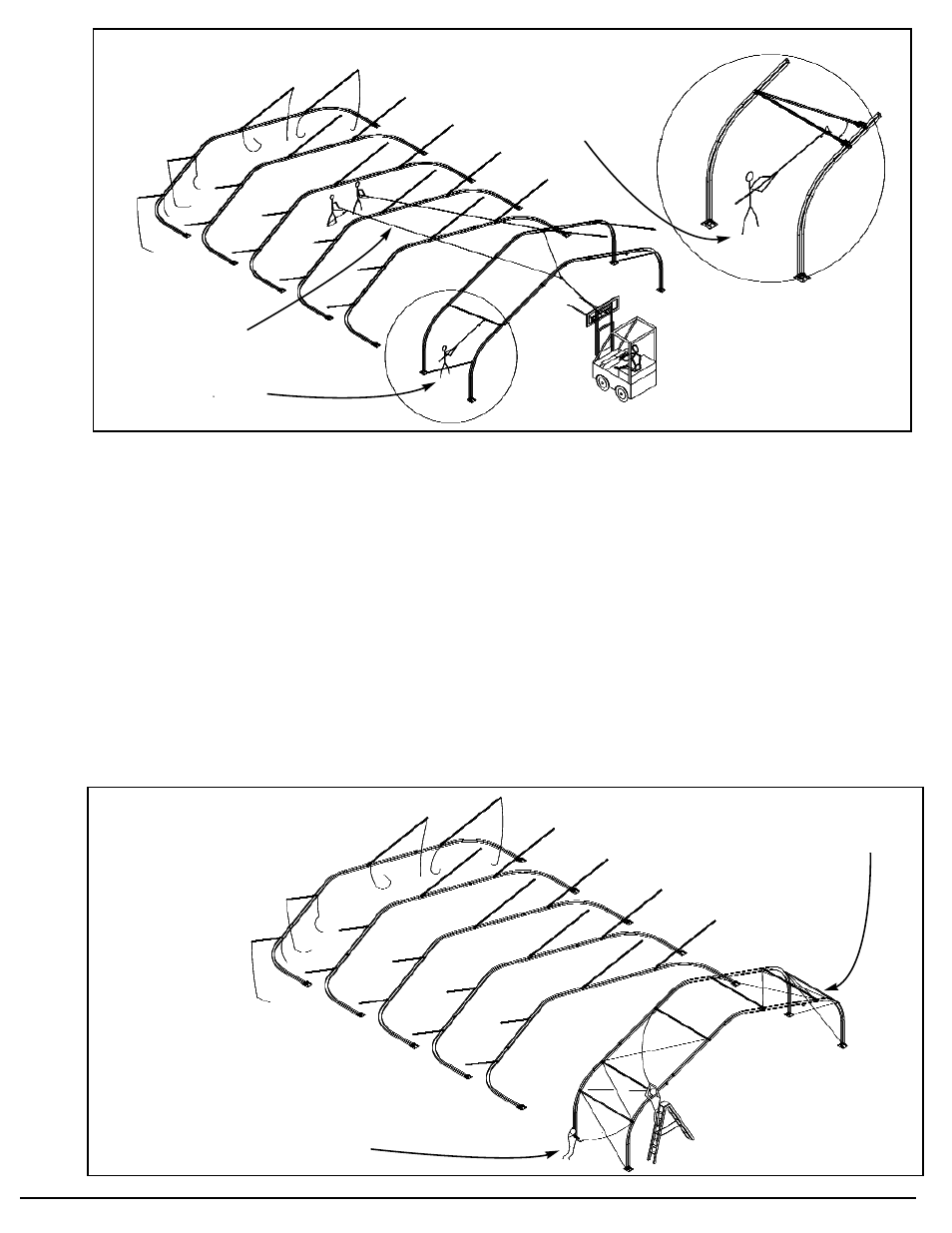

After the overhead Spanlatch purlins have been engaged between the first two beams, install eave

purlins and attach the turnbuckle ends of all X-cabling to form the “X’s” shown below (and at the

top of page 15) in the end bay of the building. (Note: eave purlins are double-latch purlins

with spanlatches on both ends.) To install them, simply raise the entire purlin above the purlin

spacer at the eave bolt, with the jaws of the spanlatch facing downward. Then, pull the purlin

downward until both spanlatches engage. (An exception to this procedure occurs in struc-

tures with only three beams total. In three-beamed structures, eave purlins will be stan-

dard spanlatch purlins, with one fixed end and one latching end.)

After the first bay is vertically aligned and X-cabled, continue raising beams by the same tech-

nique, using the purlin tool to secure the spanlatch purlins of each new beam to the beams that

are already standing until all beams are erect (see page 15). The cabling pattern will be repeated

in the last bay of the structure plus every 6th bay of the structure. No more than (5) empty bays

are allowable without X-cabling. Consult the footprint drawing if there is any doubt about the

cabling.

Safety Lines Prevent Beam

from falling toward forklift.

2nd beam pivoted same as 1st, but

secured by SpanLatch Purlins,

rather that diagonal brace.

Attach lower ends (turnbuckles) to upper holes in

SpanLatch purlin ends. Connect ALL cross-cables

loosely. Then, tighten in sequence from the ground

up, while vertically aligning the beam.

Double-Latch purlins at eaves (Except in

structures of only 3 beams, which have

Single SpanLatch purlins at eaves.)

Push SpanLatch above joint, then hook and

pull purlin downward onto Purlin Spacer to

engage and latch. Use short purlin tool on

low purlins, long purlin tool on high purlins

Engage SpanLatch Purlins between 1st & 2nd beam

Stabilize structure with cross-cabling