Anchor ANCHORSPAN A 60FT-80FT User Manual

Page 16

12

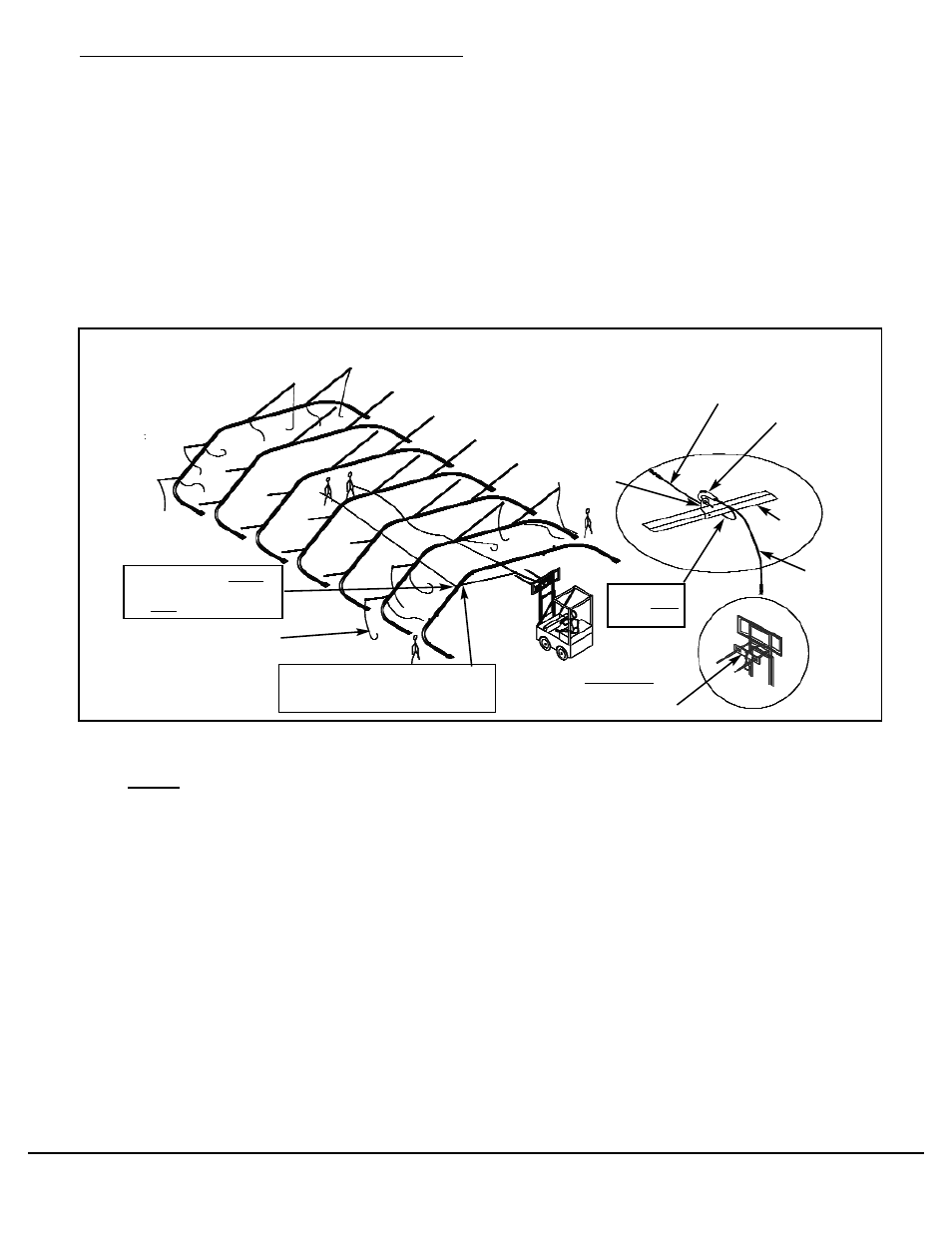

Safety Lines pass under

the beam being erected

and over remaining beams.

Cross-Cabling

Erecting Beams using the Fork Lift Method (NOTE: For an alternate method using a Gin

Pole method, see the AA AnchorSpoan Assembly Manual and increase the number of

workers pulling the beam, or reaplace them with appropriate powered equipment.)

In order to pivot the beams to a vertical position, you must pull the beam from a vertical angle.

This vertical angle can be provided by a forklift, cherry picker, crane, or any other suitable

substitute. We have chosen to show a forklift in our illustrations because they are commonly

available as rental equipment. It is important that the equipment used have a load rating and

“reach” suitable for the weight, height, and span of the beams being installed and that all rig-

ging conform to safety regulations. Cable attachments to the forklift must be secure through all

angles the cable may assume during the pivoting operation and for all heights of the forklift

mast during the process.

Install the beam hook and harnesses, as shown above, with the hooks passing through the end

beam plates at the apex joint onboth sides of the peak of the beam. Pass one end of each

cable under the beam and connect it to the safety ropes. Connect the other end of each cable

to the forklift (or other power lift). Elevate the forks to approximately 15 ft, or more, to provide a

vertical lift. The forklift operator then must coordinate the lifting of the forks and the backing up

of the forklift itself to slowly pivot the beam to vertical. Use caution to keep the angle of pull

such that the beam can pivot freely in its baseplates. Too low an angle will jam the beam

into its baseplates. Too high an angle may actually pull the baseplates from the ground. Either

of these mistakes could conceivable cause damage, or injury; so, be attentive to the smooth piv-

oting action of the beam on its baseplate pins.

The forklift operator does not have a good vantage point of the motion of the beam, so it is rec-

ommended that one worker spot the motion of the beam and signal the forklift operator as it

approaches vertical alingment. When the beam is near vertical and balanced between the fork-

lift and safety ropes held by workers, another worker can install the diagonal beam braces to

secure the first beam. (See the top of page 13). Proceed to the bottom of page 13 to erect the

second beam.

ERECTING THE FIRST BEAM

Cable harness attaches to the end

beam plates at the Apex Joint (see

end beam bolt assembly on page 9).

Use a Fork Lift Hook or

other Safety approved

quick-release attachment

Safety Line (To workers)

Beam Hook

& Harness

End Beam

Plate

Beam

Pull Rope

(to Fork Lift)

Safety Line

passes under

the beam