Erecting the 1st end beam – Anchor ANCHORSPAN AA 30FT-60FT User Manual

Page 15

12

Eyebolt/Eye Nut

Safety Lines

(Pass under the beam

being erected and over

remaining beams.)

Pull Ropes

Gin Pole

Cross-Cabling

Short Ropes attach

to metal ring

(Before Erecting beams, see optional ground installation of the Gabled End Panel on Page 18. In

other than windy conditions, this can allow the ground-lacing of gabled end panels and ease the later

installation of end uprights, as well.)

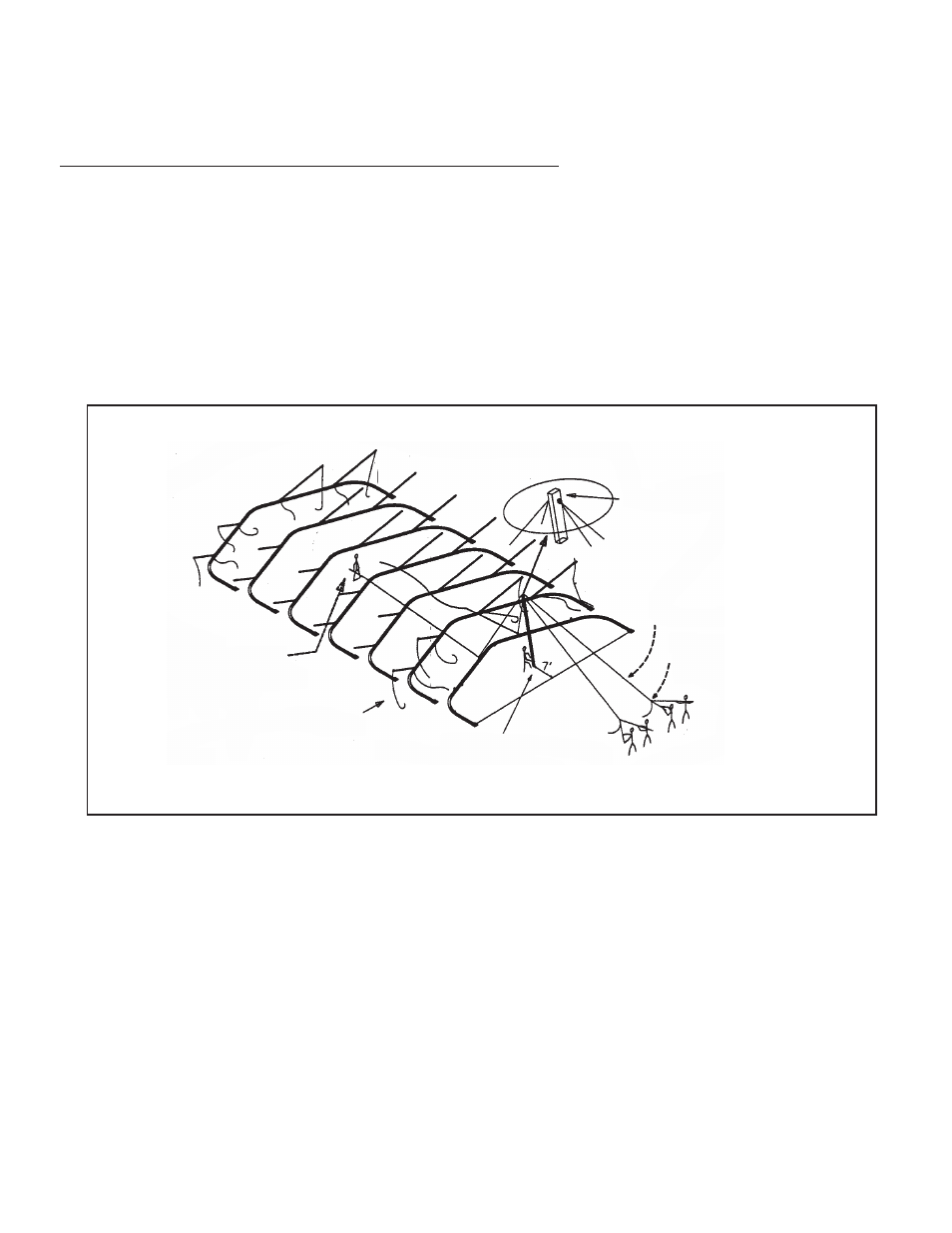

Erect Beams using the Gin Pole Method (See figure below)

Attach an eyebolt/eye nut fitting (see installation kit on Page 4) to the top of the end upright to be

used as a gin pole (the 60’ End upright for 60’spans or the adjustable upright for 30’, 40’, and 50’

spans.) Position the gin pole so that its base is approximately 7’ inside an imaginary line joining the

2 baseplates of the beam to be erected. (somewhat less for 50’, 40’, or 30’spans). Attach the hook

of the beam harness to the apex purlin plates (or the end beam bolt assembly) of the first beam to

be erected, letting the two cables attached to safety ropes trail backward under the beam. Attach

the remaining two beam harness cables to the eye of the gin pole facing the ground (see point “B”).

Avoid twisting the cable. to the gin pole eye facing the sky, attach two pull ropes and position two

workers on each, preparing to erect the beam. Follow steps below to coordinate worker positions to

safely pivot the beam to a vertical.

Erecting the 1st End Beam

“C”

“B”

“A”

Workers should NOT walk under falling path of beam. Move around to outside instead.

The Gin Pole is a center end upright (for 60’ spans) or an adjustable upright for 30,40,&50’

spans. Install eyebolt/eye nut fittings (see installation kit on Page 4) to top of upright.

60’ Procedure (1st Beam):

Step #1 (1) Worker stands gin pole, jamming base into ground surface. (“A”)

(5) Workers man pull ropes (“B”) and rotate beam to about 60 degrees vertical

Step #2 (2) Workers leave pull ropes and go to point (“C”) to man safety ropes.

(4) Workers pull beam to about 80 degrees of vertical.

Step #3 (2) Workers man safety lines preventing beam from moving beyond vertical (“C”)

(3) Workers man pull lines to hold beam near vertical (“B”)

(1) Worker leaves pull lines to install diagonal braces (as shown on next page).