Tool list, Re-aligning torque hub input coupling – JLG 4394RT Service Manual User Manual

Page 78

SECTION 3 - CHASSIS, PLATFORM & SCISSOR ARMS

3-42

– JLG Lift –

3121249

Tool List

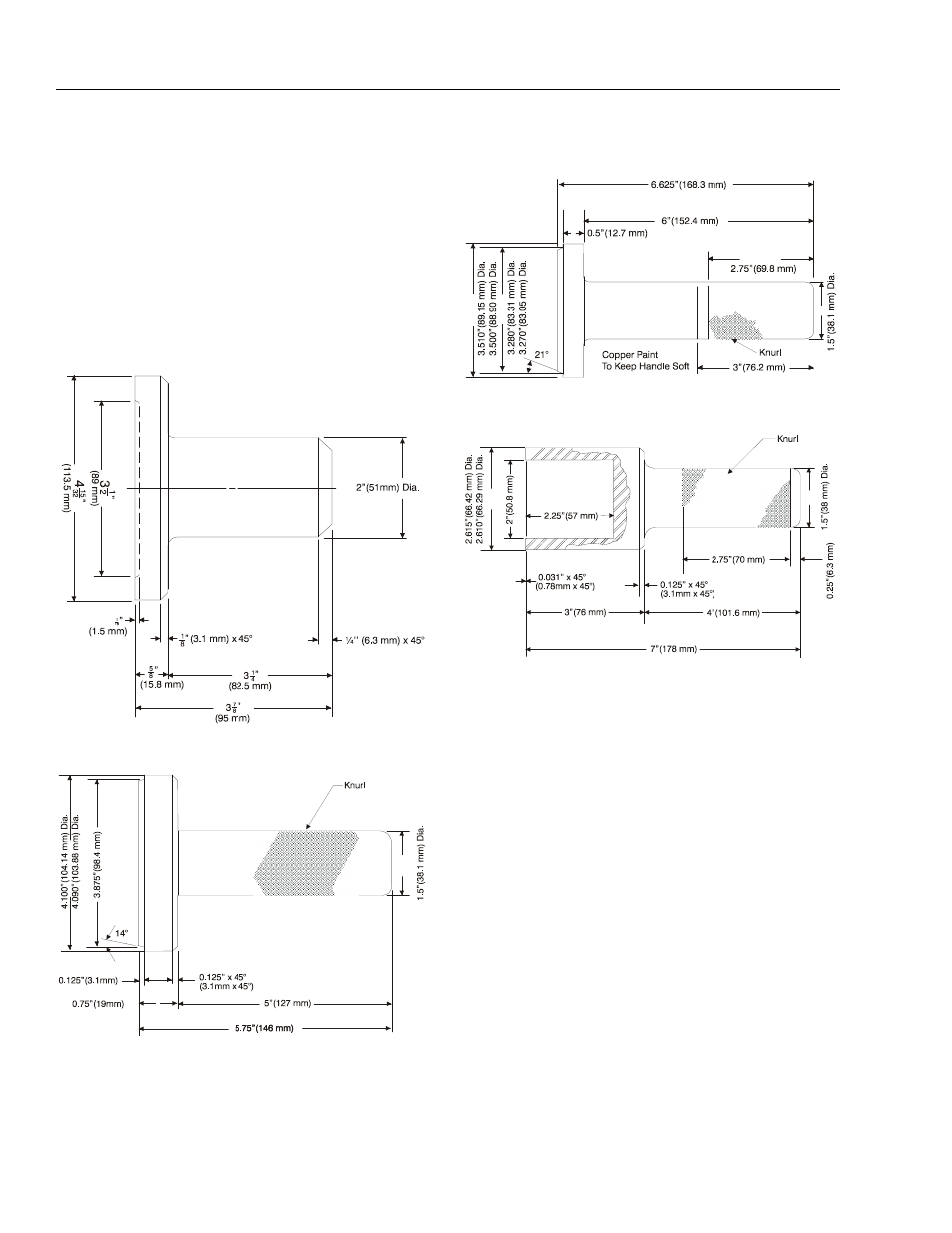

The following

specialized tools are used to assemble this

unit. The tool diagrams included in this manual are

intended for the customer who may wish to have a tool

made. All tools exist as one piece and must be made from

mild steel All dimensions are given in inches.

NOTE: In order to improve tool life, tools may be carburized

and hardened. If this is done, however, the tools

must be ground on all surfaces labeled with a "G" on

the tool diagram.

1. T-118126 SEAL PRESSING TOOL for SEAL (1B).

2. T-138903 ASSEMBLY PRESSING TOOL for CUP

(1C)

3. T-140433 ASSEMBLY PRESSING TOOL for CUP

(1E)

4. T-109691 ASSEMSLY PRESSING TOOL for CONE

(1F)

* These tools are for specific seals, cups or cones. There

is a specific tool for each cup and cone.

Re-Aligning Torque Hub Input Coupling

The following procedure applies to torque hubs with inte-

gral brakes.

EQUIPMENT REQUIRED

1. Hydraulic power supply (hand pump) capable of

producing 200 psi (13.8 bar).

2. Hydraulic fittings to adapt hydraulic supply to brake

release port on hub.

PROCEDURE

1. Using appropriate fittings, connect a line from the

hydraulic power supply to the brake port.

2. Pressurize the brake release port 155 to 200 psi

(10.6 to 13.8 bar) to release the brake.

3. Verify that the brake is released by rotating the input

coupling or hub spindle.

4. Once the brake is released, the input coupling will

be free to re-align with the drive motor.