Rod assembly installation -9, Cylinder piston nut torque specifications -9, Holding valve torque specifications -9 – JLG M4069 ANSI Service Manual User Manual

Page 81

SECTION 4 - HYDRAULICS

3121122

– JLG Lift –

4-9

EXTREME CARE SHOULD BE TAKEN WHEN INSTALLING THE

CYLINDER ROD, HEAD, AND PISTON. AVOID PULLING THE ROD

OFF-CENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON

AND CYLINDER BARREL SURFACES.

14. With the barrel clamped securely, and while ade-

quately supporting the rod, insert the piston end into

the cylinder barrel. Ensure that the piston loading o-

ring and seal ring are not damaged or dislodged.

15. Continue pushing the rod into the barrel until the cyl-

inder head gland can be inserted into the cylinder

barrel.

16. Secure the cylinder head gland using the washer

ring and socket head bolts.

17. After the cylinder has been reassembled, the rod

should be pushed all the way in (fully retracted) prior

to the reinstallation of any holding valve or valves.

18. If applicable, install the cartridge-type holding valve

and fittings in the port block using new o-rings as

applicable.

WHEN REBUILDING THE LIFT CYLINDERS, APPLY LOCTITE 242

TO PISTON NUT AND SETSCREWS.

NOTE: These cylinders use setscrews which should be dis-

carded and replaced whenever they are removed.

19. Remove cylinder rod from the holding fixture.

20. Place new o-rings and seals in the applicable out-

side diameter grooves of both the piston and the cyl-

inder head.

21. Position the cylinder barrel in a suitable holding fix-

ture.

EXTREME CARE SHOULD BE TAKEN WHEN INSTALLING THE

CYLINDER ROD, HEAD AND PISTON. AVOID PULLING THE ROD

OFF-CENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON

AND CYLINDER BARREL SURFACES.

22. With barrel clamped securely, and while adequately

supporting the rod, insert the piston end into the cyl-

inder barrel. Ensure that the piston loading o-ring

and seal ring are not damaged or dislodged.

23. Continue pushing the rod into the barrel until the cyl-

inder head gland can be inserted into the barrel cyl-

inder or if applicable until the cylinder head threads

engage the barrel threads.

24. If applicable, apply loctite #222 and secure the cyl-

inder head retainer using a suitable chain wrench.

25. Insert the other cylinder head gland into the barrel

cylinder. Secure the cylinder head retainer using a

suitable chain wrench.

26. After the cylinder has been reassembled, the rod

should be pushed all the way in (fully retracted) prior

to the reinstallation of any holding valves.

Table 4-2. Cylinder Piston Nut Torque Specifications

Description

Nut Torque Value

(Wet)

Lift Cylinder

(3369)

800 - 1000 ft lbs

(1120 - 1400 Nm)

LIft Cylinder

(4069)

1125 - 1375 ft lbs

(1575 - 1925 Nm)

Steer Cylinder

See Applicable Figure

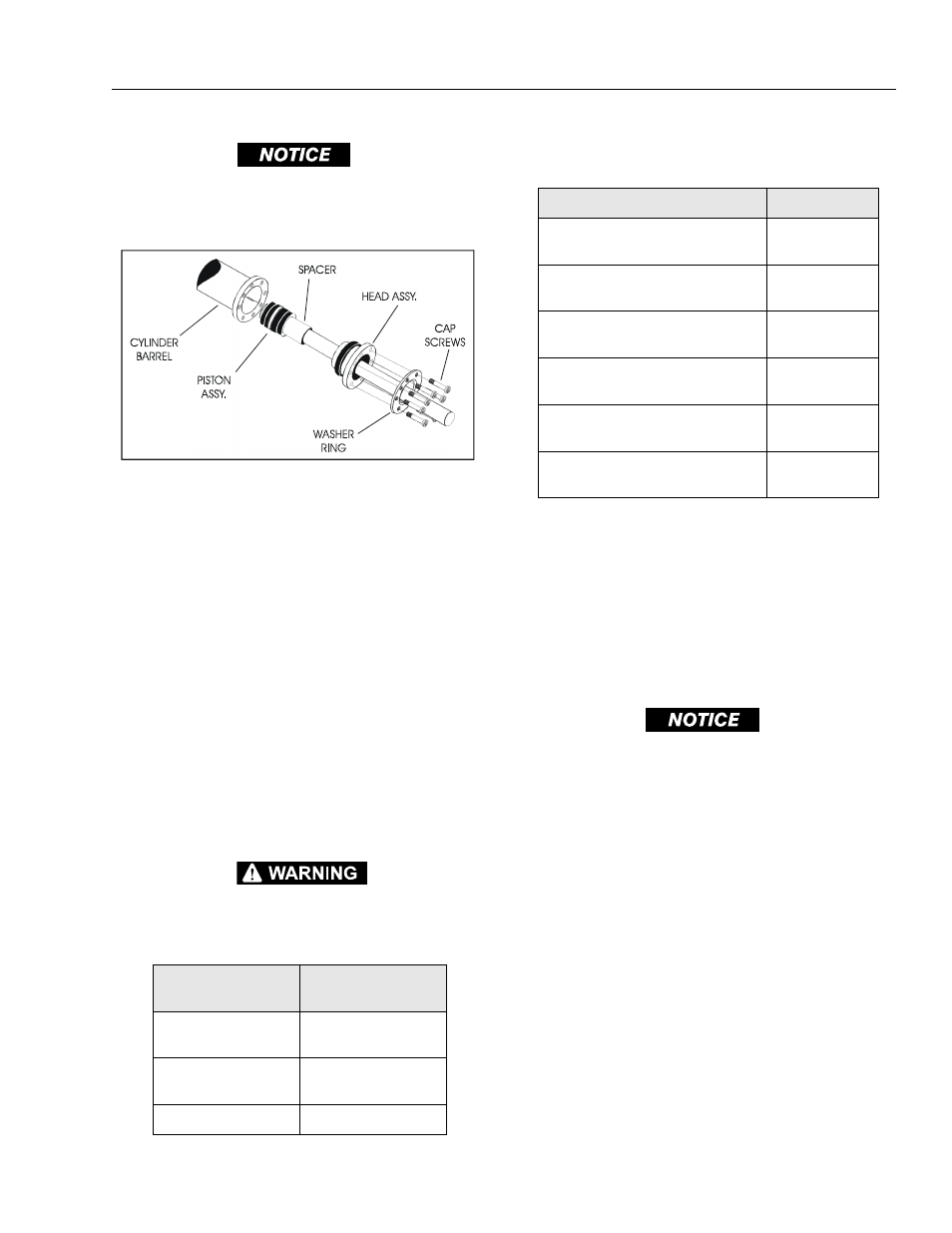

Figure 4-10. Rod Assembly Installation

Table 4-3. Holding Valve Torque Specifications

Description

Torque Value

Sun - 7/8 hex M20 x1.5 thds

30 - 35 ft lbs

(41 - 48 Nm)

Sun - 1-1/8 hex 1 - 14 UNS thds

45 - 50 ft lbs

(61 - 68 Nm)

Sun - 1-1/4 hex M36 x 2 thds

150 - 160 ft lbs

(204 - 207 Nm)

Racine - 1-1/8 hex 1-1/16 - 12 thds

50 - 55 ft lbs

(68 - 75 Nm)

Racine - 1-3/8 hex 1-3/16 - 12 thds

75 - 80 ft lbs

(102 - 109 Nm)

Racine - 1-7/8 hex 1-5/8 - 12 thds

100 - 110 ft lbs

(136 - 149 Nm)