10 lubrication, Lubrication -4, Lubrication chart -4 – JLG M4069 ANSI Service Manual User Manual

Page 12

SECTION 1 - SPECIFICATIONS

1-4

– JLG Lift –

3121122

1.10 LUBRICATION

TO AVOID PERSONAL INJURY, USE SAFETY PROP FOR ALL

MAINTENANCE REQUIRING PLATFORM TO BE ELEVATED

NOTE: Be sure to lubricate like items on each side of the

machine.

NOTE: Recommended lubricating intervals are based on

machine operations under normal conditions. For

machines used in multi-shift operations and/or

exposed to hostile environments or conditions, lubri-

cating frequencies must be increased accordingly.

*The high pressure filter is located in the main con-

trol valve. See figure title control valve in section 2.

Note:

500 Hrs. = 3 months

1000 Hrs. = 6 months

2000 Hrs. = 1 year

4000 Hrs. = 2 years

1

2

3

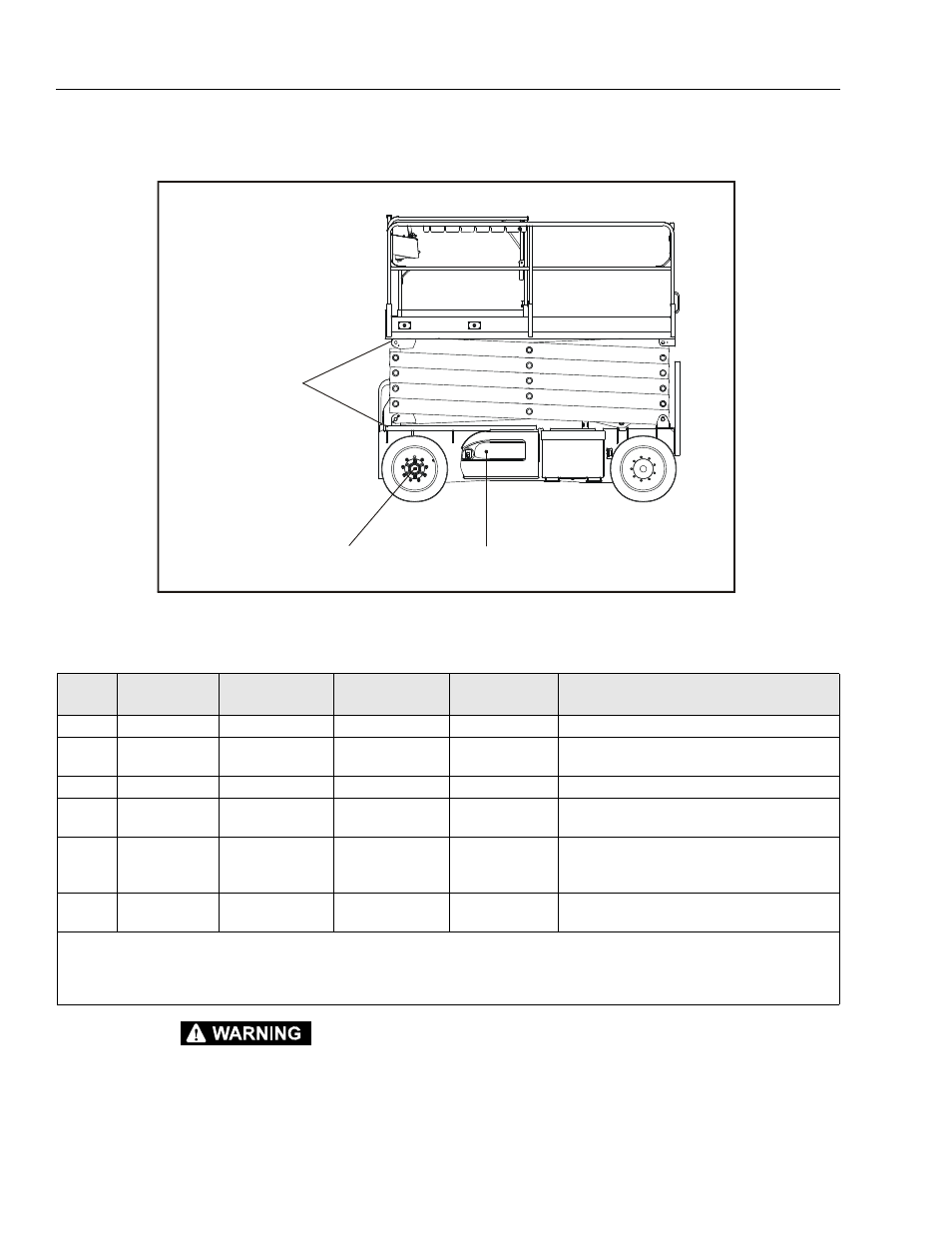

Figure 1-1. Lubrication Chart

Table 1-11. Lubrication Chart

INDEX

NUMBER

COMPONENT

NO/TYPE LUBE

POINTS

LUBE/METHOD

INTERVAL

HOURS

COMMENTS

1

Sliding Wear Pads

8 Wear Pads

MPG/Brush

50

--

2

Hydraulic Oil

Fill Level/Drain Plug

HO - Check HO Level

HO - Change HO

10/500

Check oil every 10 hours of operation

Change oil after every 1000 hours of operation

3

Wheel Bearings

Front Wheels

MPG - Repack

1200

--

4

Spindles/Bushing

(not shown)

N/A

LL

At Spindle Bushing

Replacement

--

5

Wheel Drive Hub

(not shown)

Fill Plug/Half Full

EPGL

1200

Check oil level at side plug daily.

Change after first 150 hours of operation then every

1000 hours thereafter

6

*High Pressure

Filter (not shown)

N/A

Replaceable

Element

50/250

Replace filter element after first 50 hours of operation

and every 1000 hours thereafter.

KEY TO LUBRICANTS:

HO - Hydraulic Oil - Mobil DTE - 11M

EPGL - Extreme Pressure Gear Lube

MPG - Multi Purpose Grease