Pump motor (lift), 8 features, Traction mode – JLG M4069 ANSI Service Manual User Manual

Page 76: 9 cylinder checking procedures, Cylinder without counterbalance valves (steer), Features -4, Cylinder checking procedures -4, Cutout heights -4, 8 features traction mode

SECTION 4 - HYDRAULICS

4-4

– JLG Lift –

3121122

selected, remaining until a function switch and both direc-

tions are no longer selected.

When the controller is returned to neutral, the controller

will control smooth stopping of the machine, using plug

braking, before the brake is allowed to operate.

NOTE: Depressing the lift function switch while driving will

not interrupt drive function.

Pump Motor (LIft)

Pump motor drive will start only if the following conditions

are satisfied:

1. Accelerator in neutral position.

2. Traction mode off (brake applied).

3. Depress lift select. the lights indicating lift select at

the platform control will flash. The accelerator must

be moved within 3 seconds after the lift light illumi-

nates.

NOTE: Depressing the drive function switch while lifting will

not interrupt lift function.

Any time brushes are being replaced in a drive motor

or pump motor, all brushes in the motor should be

replaced.

4.8 FEATURES

Traction Mode

NOTE: The lift up and drive functions are proportional.

The drive function is fully proportional with automatic

speed cutback above elevation. The system is designed

for maximum traction to be delivered to both wheels at all

times.

Machines equipped with oscillating axle will have oscilla-

tion below elevation cutback speed only.

4.9 CYLINDER CHECKING PROCEDURES

NOTE: Cylinder checks must be performed any time a cylin-

der component is replaced or when improper system

operation is suspected.

Cylinder Without Counterbalance Valves

(Steer)

1. Using all applicable safety precautions, activate

hydraulic system and fully extend cylinder to be

checked. Shut down hydraulic system.

2. Carefully disconnect hydraulic hose from retract port

of cylinder. There will be initial weeping of hydraulic

fluid which can be caught in a suitable container.

After initial discharge, there should be no further

leakage from the retract port.

3. Activate hydraulic system, and activate cylinder

extend function.

4. If cylinder retract port leakage is less than 6-8 drops

per minute, carefully reconnect hose to retract port

and retract cylinder. If leakage continues at a rate of

6-8 drops per minute or more, cylinder repairs must

be made.

5. With cylinder fully retracted, shut down motor and

carefully disconnect hydraulic hose from cylinder

extend port.

6. Activate hydraulic system and activate cylinder

retract function. Check extend port for leakage.

7. If extend port leakage is less than 6-8 drops per

minute, carefully reconnect hose to extend port,

then activate cylinder through one complete cycle

and check for leaks. If leakage continues at a rate of

6-8 drops per minute or more, cylinder repairs must

be made.

Cylinders With Single Counterbalance Valve

(Lift Cylinder)

OPERATE ALL FUNCTIONS FROM GROUND CONTROL STATION

ONLY.

1. Using all applicable safety precautions, activate

hydraulic system.

2. Raise platform completely and place a suitable over-

head lifting device approximately 1 in (2.5 cm) below

the platform.

3. After completing the above, shut down hydraulic

system and allow machine to sit for 10-15 minutes.

This is done to relieve pressure in the hydraulic

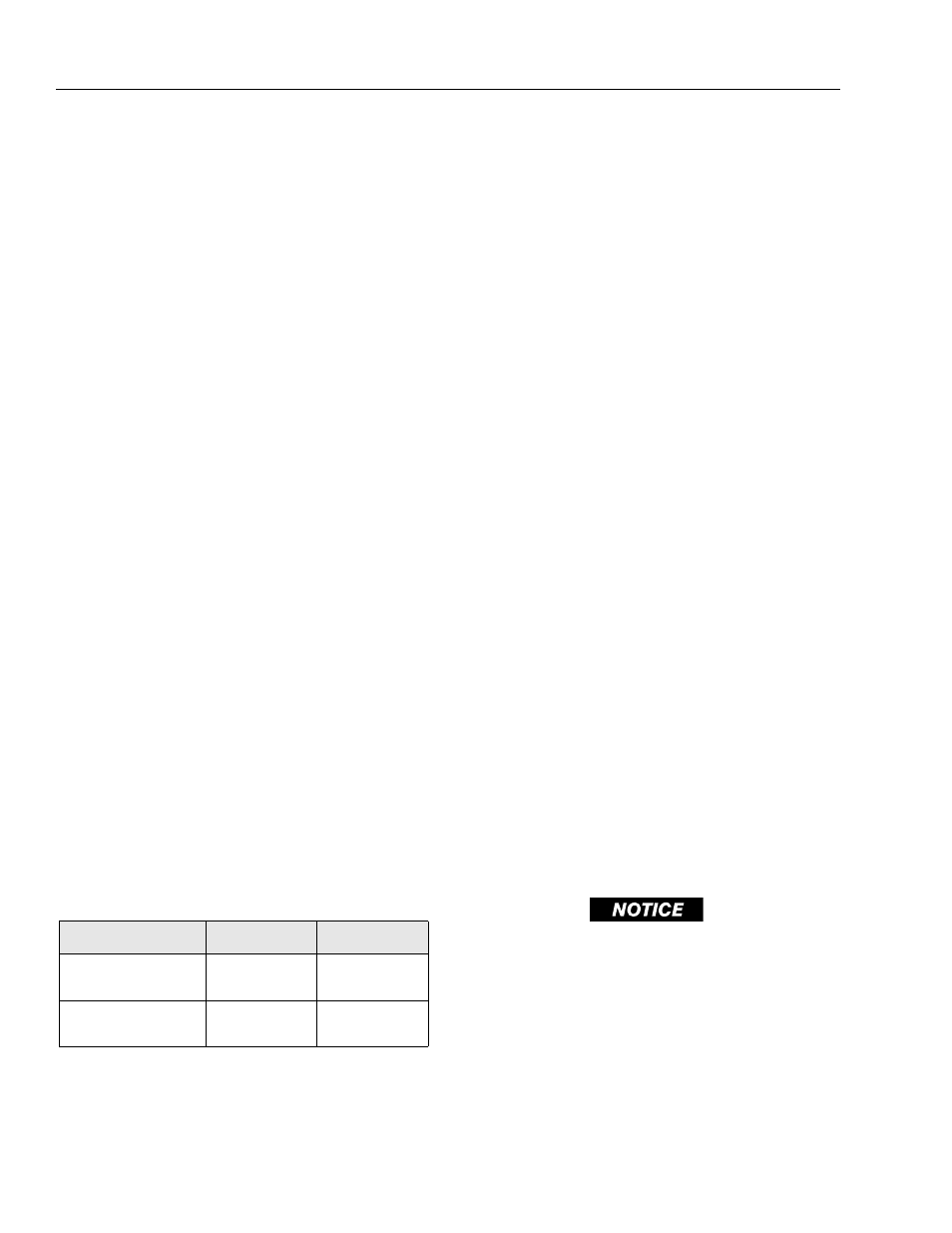

Table 4-1. Cutout Heights

Function

M3369/3369LE

M4069/4069LE

Elevated Cutback Height

8 ft - 9 ft 6 in

(2.4 m - 2.9 m)

9 ft 6 in - 11 ft 8 in

(2.9m - 3.6m)

Drive Cutout Height

N/A

28 ft - 30 ft

(8.5 m - 9.1m)