Roll test, Leak test (main unit), Tightening and torquing bolts – JLG M4069 ANSI Service Manual User Manual

Page 59: Bolt torquing sequence -31

SECTION 3 - CHASSIS & SCISSOR ARMS

3121122

– JLG Lift –

3-31

Roll Test

The purpose of the roll test is to determine if the unit’s

gears are rotating freely and properly. You should be able

to rotate the gears in your unit by applying constant force

to the roll checker. If you feel more drag in the gears only

at certain points, then the gears are not rolling freely and

should be examined for improper installation or defects.

Some gear packages roll with more difficulty than others.

Do not be concerned if the gears in your unit seem to roll

hard as long as they roll with consistency.

Leak Test (Main Unit)

The purpose of a leak test is to make sure the unit is air

tight. You can tell if your unit has a leak if the pressure

gauge reading on your leak checking fitting starts to fall

after the unit has been pressurized and allowed to equal-

ize. Leaks will most likely occur at the pipe plugs, the main

seal or wherever o-rings or gaskets are located. The exact

location of a leak can usually be detected by brushing a

soap and water solution around the main seal and where

the o-rings or gaskets meet on the exterior of the unit, then

checking for air bubbles. If a leak is detected in a seal, o-

ring or gasket, the part must be replaced, and the unit

rechecked. Leak test at 10 psi for 20 minutes.

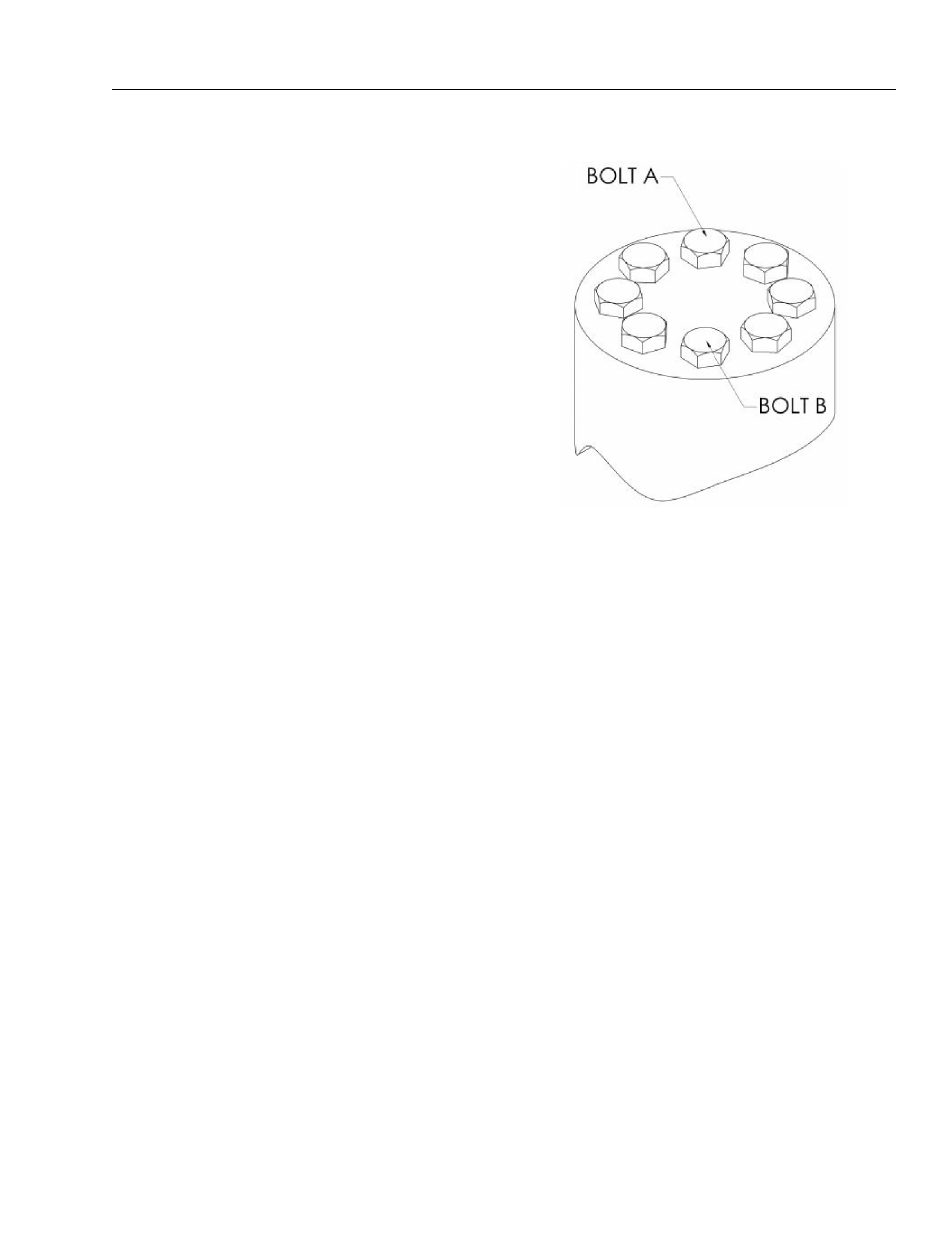

Tightening and Torquing Bolts

If an air impact wrench is used to tighten bolts, extreme

care should be taken to ensure theat the bolts are not

tightened beyond their specified torque.

The following steps describe how to tighten and torque

bolts or socket head cap screws in a bolt circle.

1. Tighten (but do not torque) bolt "A" until snug.

2. Go to the opposite side of the botl circle and tighen

bolt "B" until equally snug.

3. Crisscross around the bolt circle and tighen remain-

ing bolts.

4. Now use a torque wrench to apply a specified

torque to bolt "A".

5. Using the same sequence, crisscross around the

bolt circle and apply an equal torque to the remain-

ing bolts.

Figure 3-18. Bolt Torquing Sequence