Advance adapters, inc, Atlas 2 speed rebuild kits – Advance Adapters AB1001 User Manual

Page 4

ADVANCE ADAPTERS, INC.

4320 Aerotech Center Way, Paso Robles, CA 93446

ASSEMBLY INSTRUCTION SHEET

Page 4 of 12 Rev. Date:

06-18-08

P/N AB1000 & AB1001

ATLAS 2 SPEED REBUILD KITS

Next, remove the shifter slider, the synchronizer springs, the synchronizer dogs and the brass rings.

Turn the case so that you are looking at the input ring. Remove the six bolts that hold it to the case. Use your dead

blow hammer to firmly hit the side of the transfer case while pulling on the input shaft. The tolerance on the input bore

should be a snug fit and may take a little while to work loose. We do not recommend using any type of prying mechanism

to get the input out; the aluminum is "softer" than a screwdriver or a pry bar and WILL get damaged and my cause

problems down the road. Once removed, there will be one synchro ring that will become free. Remove it from the

case, and place it in top of the synchro hub located on the input assembly you just removed.

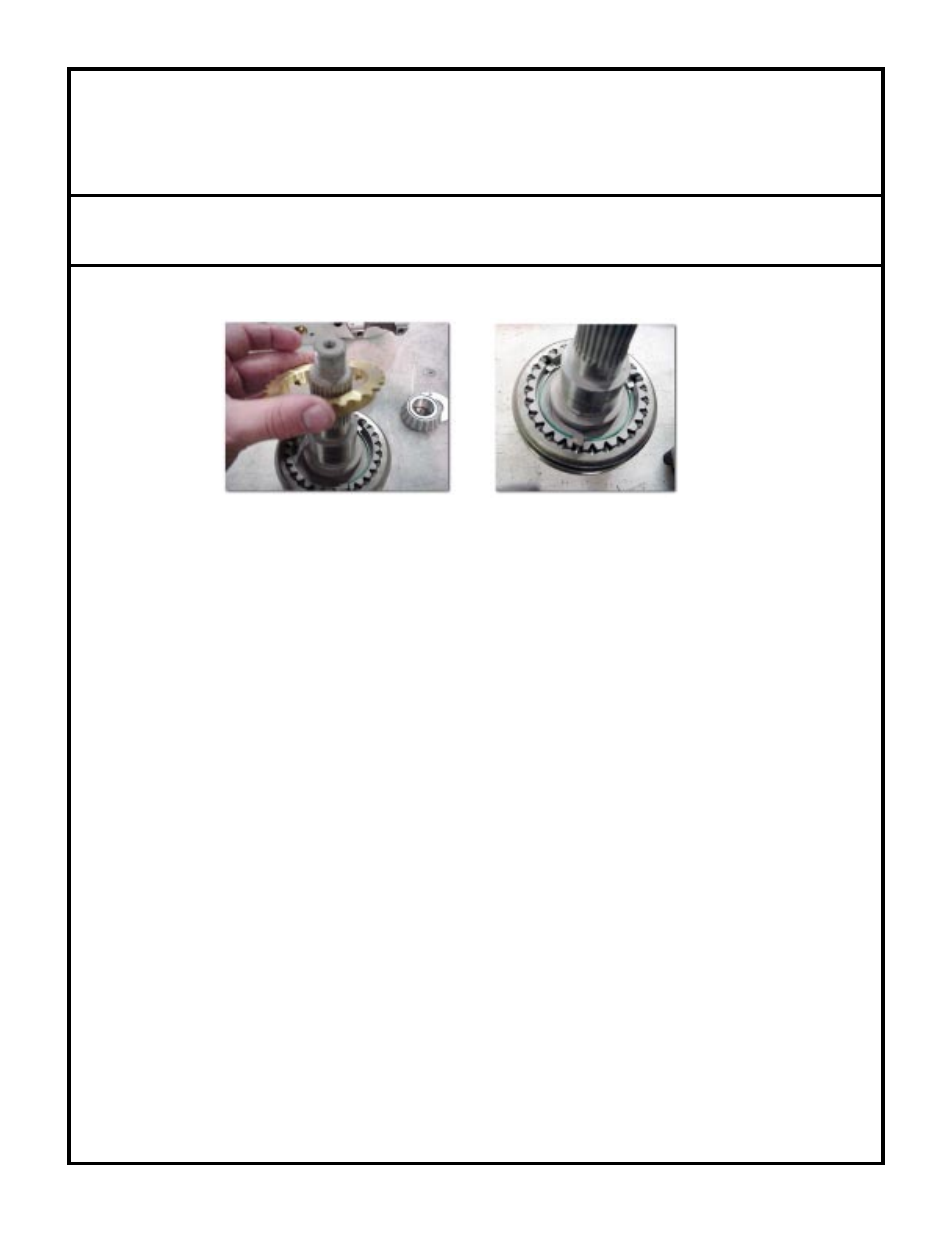

Using your fingers, "pop" the synchro slider off the slider hub. When removed, three synchro dogs will become loose.

They may simply "fall" out or even "spring" out.

Remove the speedometer drive from the tail housing. If you have no speedometer drive but do have a freeze plug

blocking the hole, disregard and go to the next step.

Using an 1-1/8" socket, remove the output shaft nut and discard it. Depending on the mileage of your unit, the rear

yoke may be difficult to remove. You can use a puller if it is stubborn but most yokes can be removed with the use

of a dead blow hammer. When the nut and yoke are off, the output shaft will become "loose" in the case. DO NOT

ATTEMPT TO REMOVE THE OUTPUT SHAFT FROM THE CASE YET! There are a couple of parts which

are still holding it into the case.

Remove the five bolts holding the tail housing on the case. You may need to tap the tail housing to get it loose from

the case. Take the housing completely off the case and set it aside.

Use a set of snap ring pliers to remove the first snap ring from the shaft. Next, remove the blue plastic drive gear from

the shaft (may be a slightly snug fit). Remove the last snap ring and set those parts aside.

The last thing holding the shaft into place is the bearing on it. This bearing is another "light" press, and will require the

use of the dead blow hammer. Use one hand to hit the tip of the shaft with the hammer and the other hand to support

the large "pancake" gear inside the case. Visualize that you are driving the output shaft through the pancake gear and

out the front of the case. When the bearing becomes loose, slide it completely off of the shaft. Place it into the "old"

parts section. Pull the shaft fully from the front of the case. There is one more brass synchro slider, and one caged

needle bearing set that are now free. Remove the pancake gear from the case. There should not be any more parts

loose inside the case. At this point it is wise to clean and inspect your case and parts for any debris. Also inspect the

outside of the case and remove any silicon or sealing material.

Place the pancake gear on a flat surface with the synchro hub facing up. Take one of the brass synchro rings and place