JLG G6-42P Service Manual User Manual

Page 317

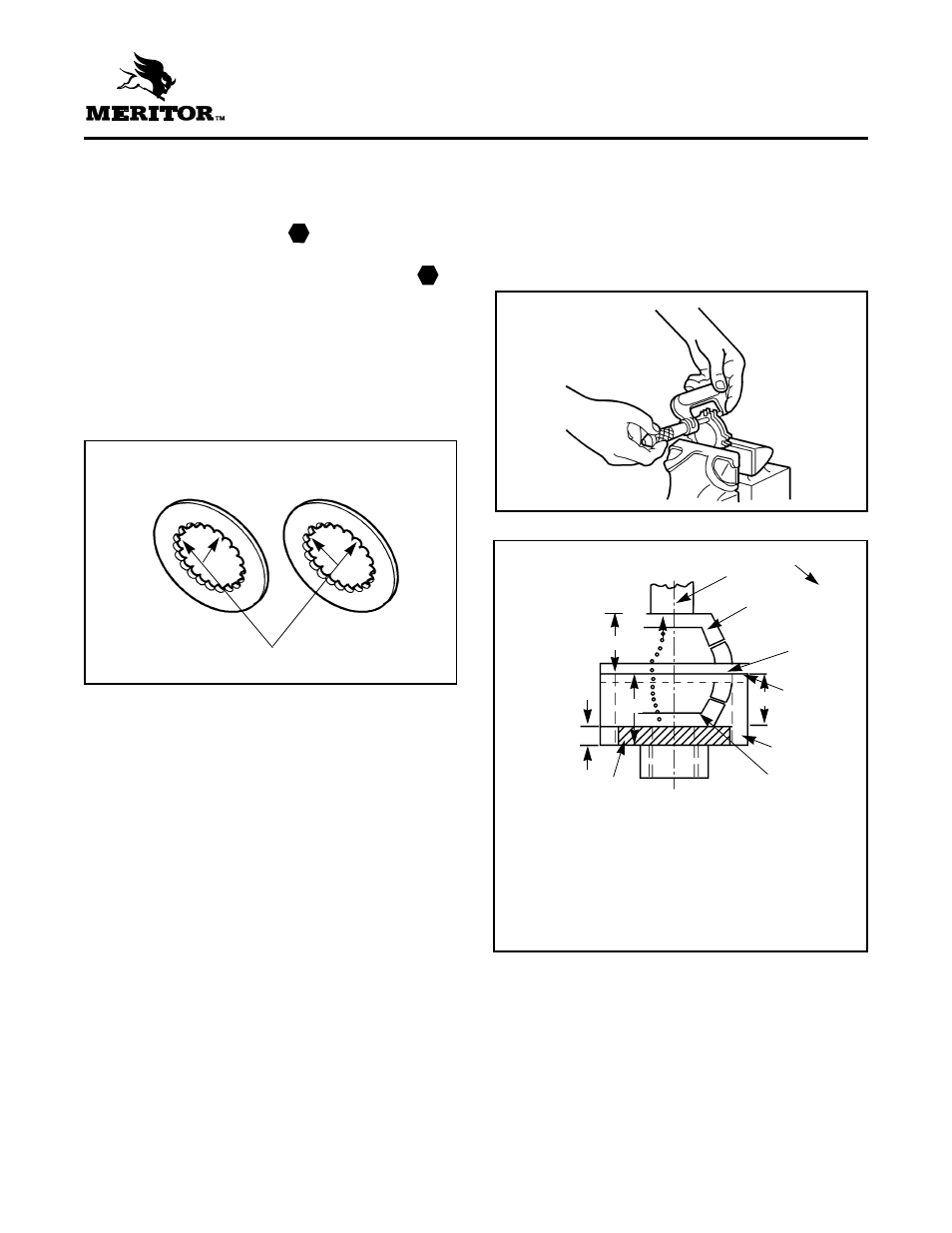

d. Place disc pack stack in vise. Use micrometer

to determine “D”, the height (thickness) of

limited slip disc stack (includes thrust washer

and compression disc). Take four readings,

one at each of four points. Average readings

to determine “D”. Figures 4.8 and 4.9.

25

Section 4

Assembly and Installation

10. Apply Loctite 271 or Three Bond 1305 liquid

adhesive to capscrews. Install four capscrews

into case halves equally spaced and tighten to

48-64 lb-ft (64-87 N•m).

11. Install other capscrews into case halves. Tighten

the capscrews to 48-64 lb-ft (64-87 N•m).

12. Assemble Limited Slip Differential Case.

a. Follow steps 1 to 5.

b. Place flanged case half on bench.

c. Begin stacking of the disc pack with a drive disc

followed by driven friction discs. Make sure

lubrication grooves are aligned. Figure 4.7.

Maintain the following sequence:

1) Drive disc

2) Driven friction disc

3) Drive disc

4) Driven friction disc

5) Drive disc

6) Driven friction disc

7) Drive disc

8) Shims (Do not stack until measurements are

complete.)

9) Compression disc

10) Thrust washer (on side gear side)

Figure 4.8

Figure 4.7

Figure 4.9

LUBRICATION GROOVES

TOP

PLAIN HALF

SIDE GEAR

PLAIN HALF

SIDE GEAR

LIMITED

SLIP PACK

PLAIN HALF

DIFF GEAR

PLAIN HALF SIDE

GEAR MOVED TO

DETERMINE “A”

D

A

B

C

SPIDER

DIFF CASE

FACE

(DATUM)

A: Differential case half flange to back of

differential side gear distance.

B: Differential case face to side gear seat.

C: Differential case half depth.

D: Stack height (thickness).

e. Use depth gauge to determine “C”, depth of

differential case half. Take four readings.

Average readings for result. Figure 4.9.

T

T