Disassemble trumpet assembly – JLG G6-42P Service Manual User Manual

Page 295

Section 2

Removal and Disassembly

CAUTION

Loosen and remove brake cylinder capscrews

alternately to avoid spring load damage to parts.

5. Disassemble brake cylinder assembly. Remove

brake release capscrew. Loosen and remove

brake cylinder capscrews alternately to avoid

spring load to be supported by only one capscrew.

6. Remove spring, piston and O-ring seals. Do not

cut or scratch them.

7. Clean cylinder and brake support surfaces. Do

not damage ground surfaces.

8. Put parts of each brake cylinder assembly in

separate plastic bags to avoid mixing them.

Disassemble Trumpet

Assembly

WARNING

To avoid serious personal injury and possible

damage to components, be very careful when

using lifting devices during removal and

disassembly procedures.

•

Inspect to make sure that neither lifting strap is

damaged.

•

Do not subject lifting straps to any shock or

drop loading.

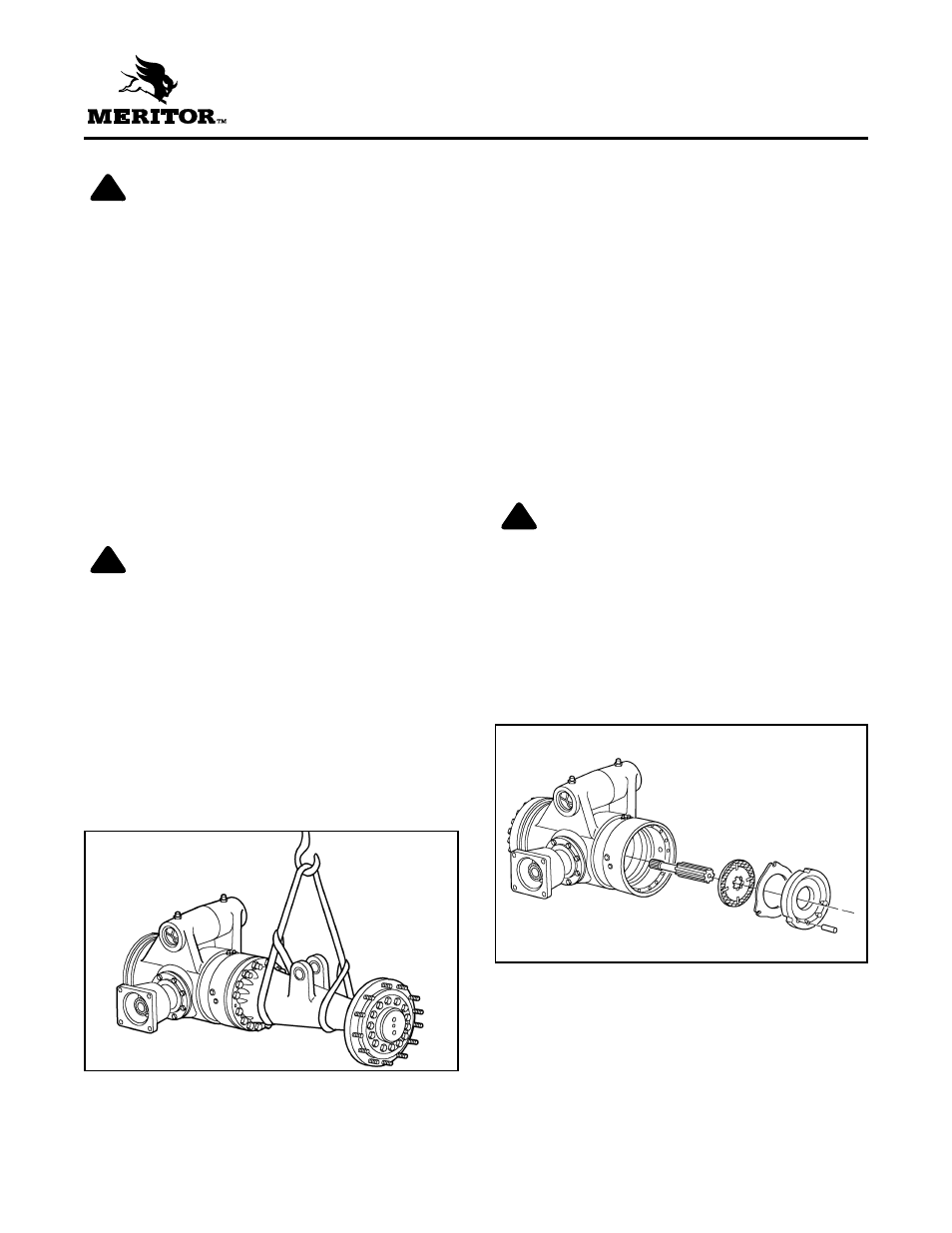

1. Support trumpet to be serviced with lifting device.

Figure 2.3.

2. Loosen and remove trumpet nuts and bolts.

!

!

3

NOTE

For three function brake design: If bleeder and

pressure ports of brake piston are open, the

trumpet assemblies and ring gear will come off

the center section easily without using puller

holes. Cover pressure ports with rags to avoid

contact with escaping oil.

3. Use two puller holes in trumpet flange to remove

trumpet assembly from main housing.

NOTE

Use steps 1 through 3 to remove second trumpet

assembly.

4. Remove ring gears from both sides through the

two threaded puller holes.

(Thread: M14 x 1.5 x 6 g).

WARNING

Do not hit steel parts with a steel hammer during

removal and disassembly procedures. Parts can

break and cause serious personal injury.

5. From main housing, remove sun axle shaft,

spacers (if used), compression plates, stationary

discs, friction discs, lock pins and expansive

plate assemblies. To make lock pin removal

easier, hit main housing with brass hammer.

Figure 2.4.

!

Figure 2.3

Figure 2.4