Danger, Caution – Burnham MEGASTEAM MST288 User Manual

Page 31

31

2. Type B Chimney Connector - a type B chimney

connector can be used to transmit the flue gases

provided flue gas temperature entering the chimney

connector is greater than 310°F.

3. Type L Chimney Connector - a type L vent or

other suitable material shall be used for a chimney

connector if the temperature or exiting temperature

is less than 310°F.

DANGER

Any signs of condensate seepage at the base of

the chimney shall be inspected immediately. The

discoloration may be a sign of chimney damage

and must be remedied immediately.

C. DRAFT

1. The natural draft generated through a chimney is

dependent on several factors including, chimney

height, temperature of flue gases, cross section area

of chimney, chimney wall insulation value, dilution

air and total volume of flue gases, to name a few.

Make sure that the boiler has been running for at

least 5 minutes before measuring the draft.

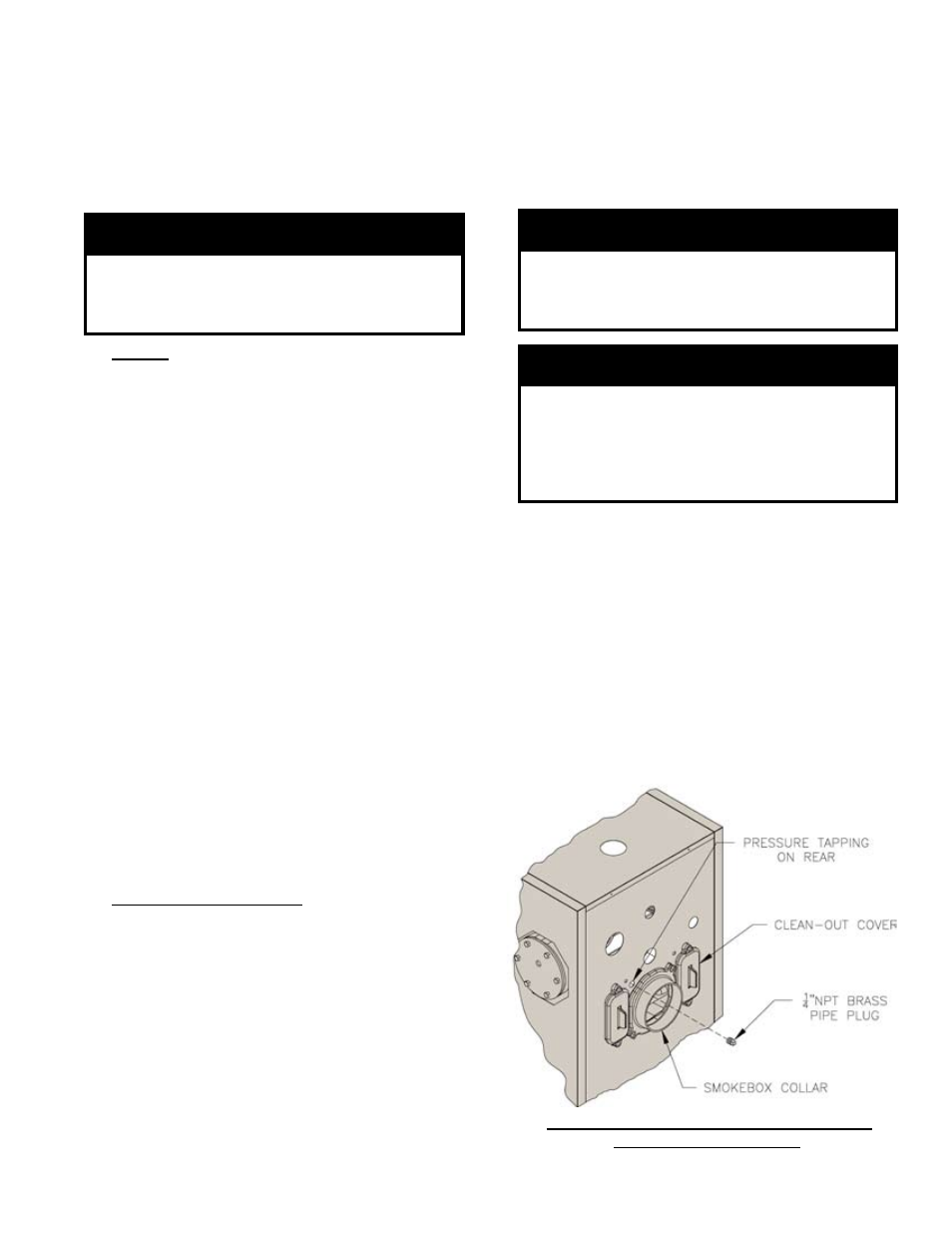

2. Minimum Draft at Breech (Canopy) – The draft

induced by a chimney must create at least a

pressure of 0 (zero) inches water column (“ w.c.)

at the pressure tapping on the canopy mounted

on rear of boiler (see Figure 17). The pressure

at the canopy cannot be positive since this could

create a condition that allows flue gas by-products

to escape from the draft regulator. A negative

pressure reading up to -.03 inches water column

is acceptable for proper operation. (See Table 8,

Burner Specifications at the rear of this manual for

more details)

3. Minimum Overfire Pressure – The overfire

pressure is another piece of information that is

often measured, however this should be done for

observation purposes only! The breech pressure

must be used to qualify the draft condition. See

Table 8 for more details as a guide. Actual draft and

temperature measurements may be different then

those values in the table.

D. STACk TEMPERATURE

1. The temperature of the flue gases has a significant

effect on the amount of draft created in a vertical

chimney as well as the propensity to create

condensate. The higher the stack temperature, the

greater the amount of draft that can be generated. A

lower stack temperature not only reduces the amount

of draft that can be created but it also increases the

possibility that the flue gases could condense in the

chimney connector or stack.

2. NFPA 31 has information to help the installer

make an appropriate choice of venting materials.

In some cases a chimney may have to be lined to

create sufficient draft. In other cases, the chimney

may have to be lined to prevent the corrosion

of a masonry chimney. Consult with a chimney

specialist knowledgeable on the requirements for

chimney requirements in your area.

CAUTION

Any doubt on the condition of a chimney

or it's ability to prevent the generation and

accumulation of flue gas condensate, must be

relined according to NFPA31.

CAUTION

Use the chimney venting tables as a guide. It

is highly recommended that any borderline

application should result in the relining of the

chimney with a suitable liner that creates sufficient

draft and to protect against corrosion caused by

flue gas condensate.

3. Baffles – The efficiency of the boiler is based on the

insertion of flue baffles supplied with your product.

Under no circumstances are other baffles to be used

on this product. The baffles are installed in the 2

nd

pass (two inner flueways) on the MST396, MST513

and MST629 Refer to Section II, Item E, Paragraph

1 for baffle installation. If there is any doubt

on the application of this boiler on the intended

chimney, consult with your local code officials.

At a minimum, remove the baffles to increase the

stack temperature. See Table 8 for temperature

differential (∆T) with baffles IN and OUT. In

addition, the lower the CO

2

level the higher the

stack temperature.

Figure 1: Smokebox Pressure Tapping for

Checking Draft at Breech