Caution – Burnham MEGASTEAM MST288 User Manual

Page 14

14

E. FLUEwAY BAFFLE INSTALLATION.

Flueway baffles are enclosed into Part Carton. Baffle

requirements differ by boiler model, see Table 2.

TABLE : BAFFLE USAGE

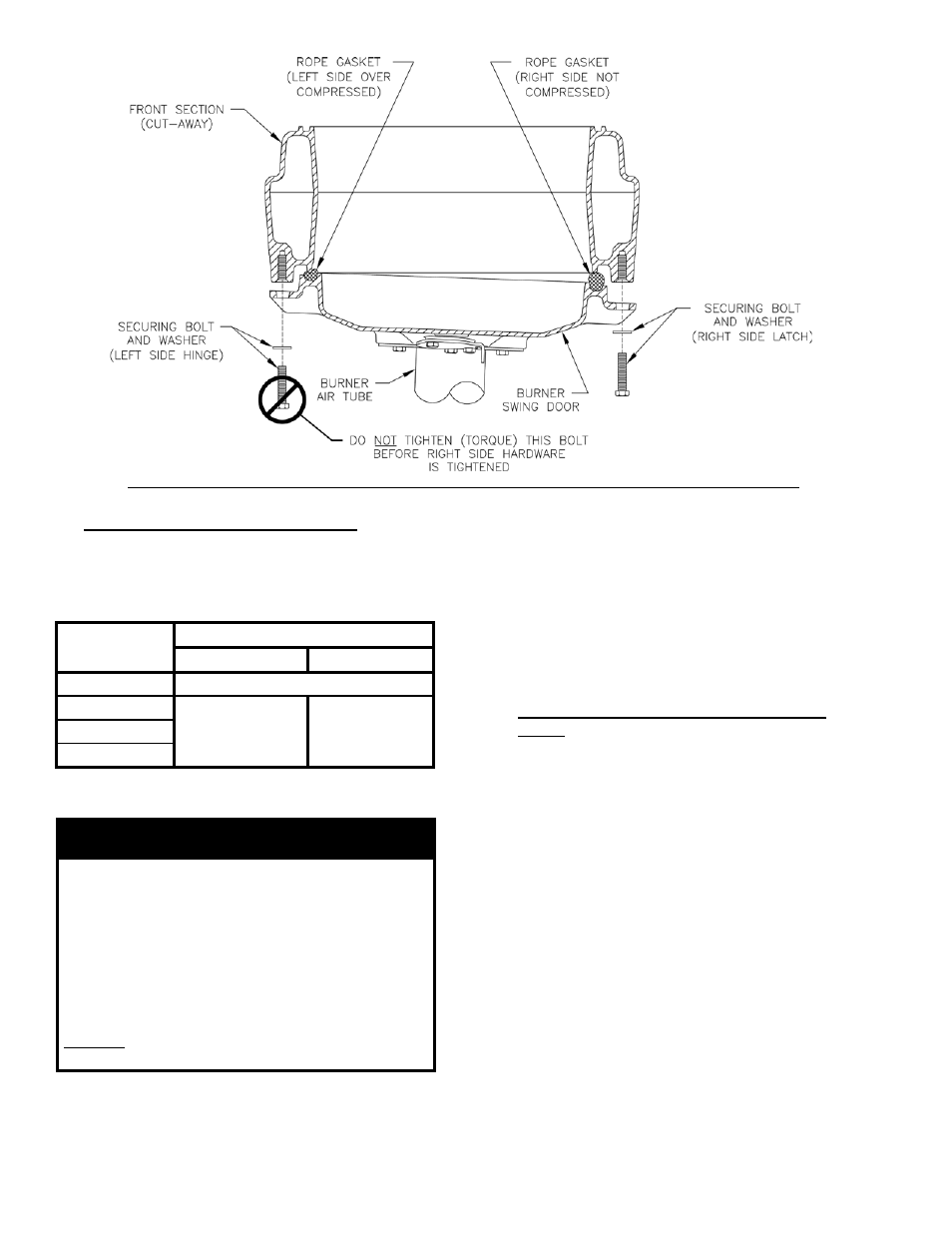

Figure 5C: Top View - Burner Swing Door Fully Closed but Not Properly Secured or Sealed

NOTE: Read caution statement before proceeding.

CAUTION

These baffles will generate higher efficiencies

and lower stack temperatures. Under certain

conditions, a lower gross stack temperature

entering the chimney has the potential to

be cooled below the dew point and create

condensate on interior surfaces. Flue gas

condensate is corrosive, which requires

special consideration and must be addressed

immediately.

DO NOT install baffles until you have read

Section V, "Venting" completely.

1. To install flueway baffles, provided in miscellaneous

part cartons, as follows, refer to Figure 6 and

Table 2:

•

Models MST396, MST513 and MST629 - To

install flueway baffle in 2

nd

pass flueway on

left side of boiler, hold baffle with word "Left"

readable at the top. Slide baffle in flueway until

position tab touches fins on right side of 2

nd

pass

flueway. To install flueway baffle in 2

nd

pass

flueway on right side of boiler, hold baffle with

word "Right" readable at the top. Slide baffle

in flueway until position tab touches fins on left

side of 2

nd

pass flueway.

F. CLOSING / SECURING BURNER SwING

DOOR.

1. To close and secure Burner Swing Door:

a. From fully open position, rotate the door to the

closed position.

b. Lift door upward into the build-in cast ramp/door

rest (protruding from the bottom of the front

section casting – see Figure 5A).

c. Use one hand to apply pressure directly to the

door to hold it in closed position while re-

installing earlier removed door-latching hardware

(3/8”-16 x 1-3/4” tap bolt and 5/16” washer).

Prior to re-installation, apply a drop of supplied

Anti-seize (pouch provided in Part Carton) to

both tap bolts for rust protection and to facilitate

easy removal, if burner door is to be open for

inspection and service. ALWAYS INSTALL

RIGHT SIDE LATCHING HARDWARE FIRST,

THEN INSTALL EARLIER REMOVED LEFT

SIDE HINGE HARDWARE (3/8”-16 X 1-3/4”

TAP BOLT AND 5/16” WASHER) SECOND.

Apply additional pressure while hand tightening

the hardware as far as possible and then release

the pressure.

Boiler

Model

Baffle Usage

2

nd

Pass

3

rd

Pass

MST288

None

MST396

(2)

P/N 100042-01

None

MST513

MST629