Notice – Burnham MEGASTEAM MST288 User Manual

Page 15

15

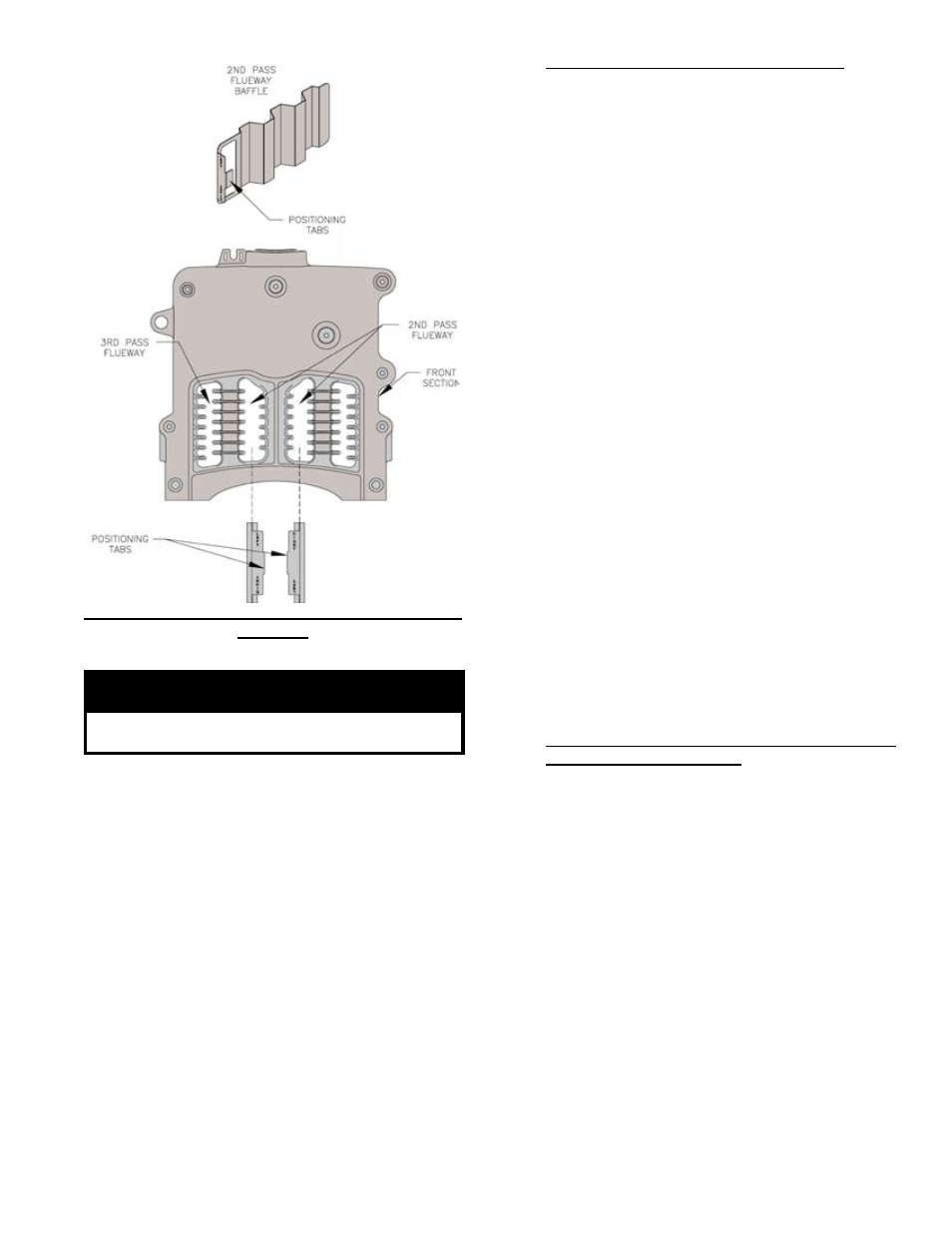

Figure 6: Flueway Baffle Positioning/Orientation in

Flueways

NOTICE

When securing burner swing door make sure door

is drawn-in equally on both sides.

d. Use a hand or socket wrench to tighten door

hardware. ALWAYS START WITH RIGHT

SIDE TAP BOLT FIRST. Use an alternating

tightening method from right side tap bolt to

left side tap bolt to tighten door equally, until

sealed, without applying excessive torque.

NEVER TIGHTEN LEFT SIDE TAP BOLT

FIRST, OR, EITHER PIECE OF HARDWARE

100% WITHOUT USING THE ALTERNATING

METHOD DESCRIBED ABOVE. See Figure

5B.

e. Failure to follow the prescribed procedure could

cause thread damage to casting and /or leak at

the door seal. IF LEFT SIDE TAP BOLT IS

TIGHTENED BEFORE RIGHT SIDE TAP

BOLT, RIGHT SIDE OF THE DOOR CAN

NOT BE DRAWN-IN TO PROVIDE AN AIR-

TIGHT SEAL, as shown in Figure 5C. Applying

excessive torque will only cause thread damage.

G. JACkET REAR PANEL INSTALLATION.

1. Locate jacket rear panel (has factory attached 3”

fiberglass insulation) inside Jacket Carton. See

also “Repair Parts” Section, “Jacket Assembly”

illustration for part identification.

2. Locate and remove from Hardware Bag rear panel

mounting hardware – (2 pcs) 5/16”-18 x 3” lg. tap

studs, (2 pcs) 5/16”-18 plated acorn nuts, (2 pcs)

5/8” x 2-9/32” round spacers and (2 pcs) 5/16”-18 x

½” Phillips pan head machine screws.

3. Locate rear panel two lower attachment bosses on

rear section. See Figure 7 “Purpose of Tappings &

Bosses”.

4. Thread both 5/16”-18 x 3” lg. tap studs, with short

threaded end, into lower attachment bosses on rear

section.

5. Install both 5/8” x 2-9/32” round spacers over tap

studs.

6. Place rear jacket panel over rear section, so both

tap studs clear thru lower panel holes, rear section

cleanout openings clear thru matching panel cutouts

and brass sample port plug clears panel matching

hole.

7. Secure panel bottom to studs with acorn nuts hand

tight.

8. Align upper panel attachment holes with smokebox

upper attachment bosses and install 5/16”-18 x ½”

Phillips pan head machine screws hand tight.

9. Securely tighten rear jacket panel mounting

hardware.

10. Locate/remove four #8 x ½” shoulder sheet metal

screws from Hardware Bag, then, install them into

rear panel flange holes.

H. FLUE CLEANOUT COVERS AND SMOkEBOx

COLLAR INSTALLATION.

1. Remove two cast iron Cleanout Covers, cast iron

Smokebox Collar and the tube of hi-temperature

silicon adhesive sealant from Part Carton. See also

“Repair Parts” Section, “Bare Boiler Assembly”

illustration for part identification.

2. Check the rope gasket factory attached to the covers.

Repair or replace, if the rope is damaged, or, there is

a gap between the rope ends.

3. Locate/remove four 5/16”-18 – 7/8” hex head cap

screws from Hardware Bag.

4. Apply a drop of supplied Anti-seize (pouch provided

in Part Carton) to each of four (4) 5/16”-18 x 7/8”

hex head cap screws for rust protection and to

facilitate easy removal for future service.

5. Position left Cleanout Cover over rear section

cleanout opening, align section boss holes with

Cleanout Cover holes, install both 5/16”-18 – 7/8”

hex head cap screws hand tight, then, alternately

tighten them with open end or socket wrench.