Caution – Burnham MEGASTEAM MST288 User Manual

Page 18

18

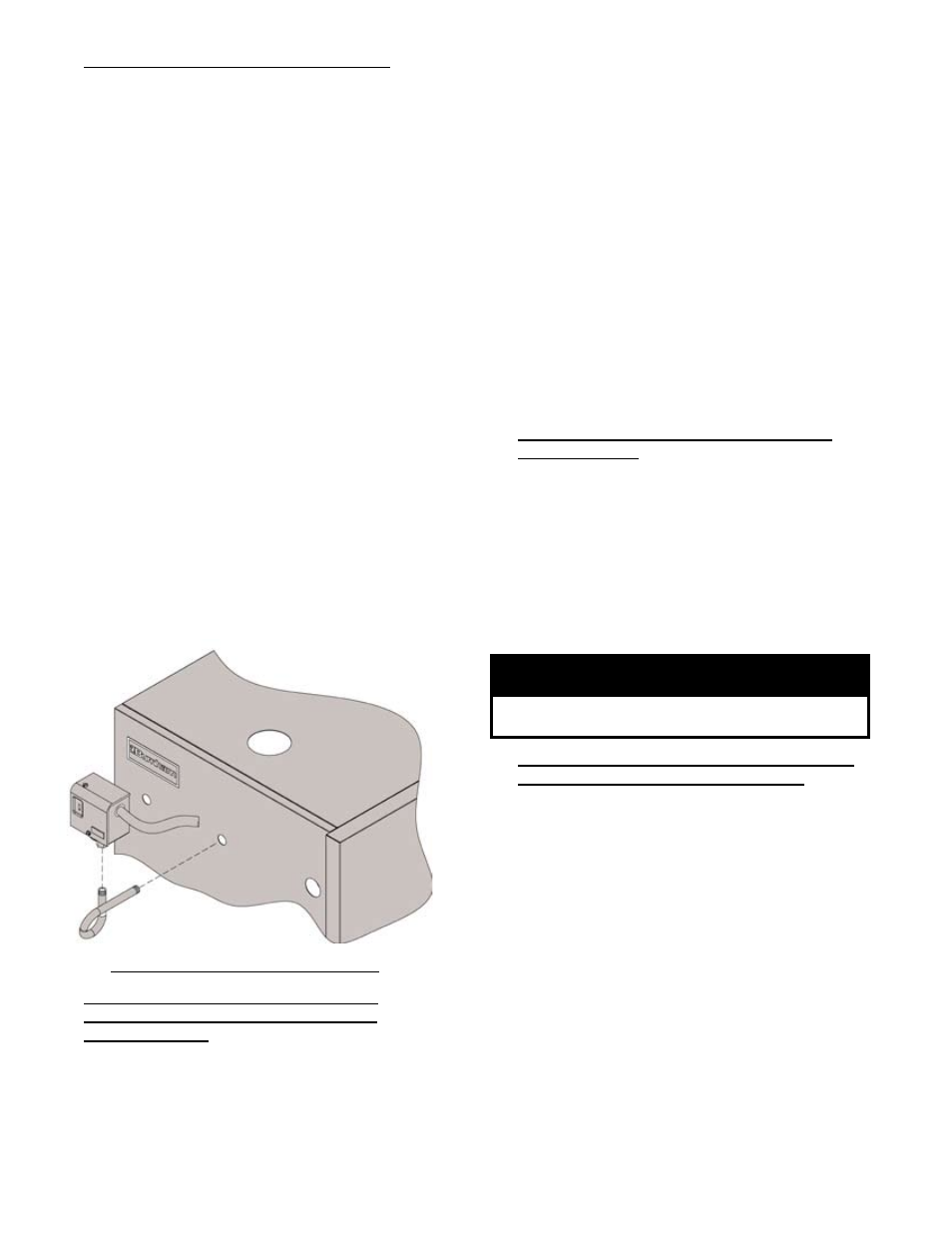

L. TRIM AND CONTROLS INSTALLATION.

Pressure Limit Installation.

1. Locate and remove L404F Pressure Limit with

factory attached harness from Control Carton.

2. Locate and remove 1/4" NPT x 1-7/8" x 4 x 90°

syphon enclosed in Part Carton.

3. Review and locate pressure limit tapping on front

section. See Table 3 “ Purpose of Tappings &

Bosses” and Figure 7.

4. Thread 1-7/8" lg. syphon-threaded short end into

the bottom of Pressure Limit with factory attached

harness. Do not tighten the syphon by holding the

limit case; apply a wrench to the brass hex below

the case.

5. Thread ¼" NPT x 4" lg. syphon-threaded long end

into pressure limit tapping on front section. See

Figure 8 "Pressure Limit Installation.

6. L404F pressure limit does not require leveling. The

pressure limit final orientation must be parallel to

boiler front, having the harness on the right side.

7. Pick-up the pressure limit harness Molex end and

feed it into the enclosure, thru top flange rear left

7/8” hole; then, snap-in harness BX connector into

the hole, and, plug Molex connector into dedicated

pressure limit receptacle inside the enclosure (upper

left off transformer/relay). See “ Control Plug-In

Diagram” label attached to inside of the enclosure

cover for details.

Figure 8: Pressure Limit Installation

M. PROBE LwCO (HYDROLEVEL CG450,

OR, MCDONNELL-MILLER PS801-120)

INSTALLATION.

1. Remove either Hydrolevel CG450 LWCO with

factory attached harness and Hydrolevel probe

#EL1214, or, McDonnell-Miller PS801-120 with

factory attached harness and #153875 probe from

Control Carton.

2. Install the probe into the appropriate front section

tapping. See Figure 7 “Purpose of Tappings &

Bosses”.

3. Slip LWCO with factory attached harness over the

probe and clamp in place. Note that CG450 LWCO

will be positioned right side up, with diagnostic

LED(s) on the top flange, while PS801 LWCO

will be positioned upside down, with diagnostic

LED(s) on the bottom flange. Connect the wire(s)

between the probe and control per manufacturer’s

instructions.

4. Pick-up the LWCO harness Molex end and feed it

into the enclosure, thru external electrical enclosure

top flange front left 7/8” hole; then, snap-in harness

BX connector into the hole, and, plug-in Molex

connector into dedicated LWCO receptacle inside

the enclosure (middle left off transformer/relay). See

“ Control Plug-In Diagram” label attached to inside

of the enclosure cover for details.

N. PRESSURE GAUGE AND GAUGE GLASS

INSTALLATION.

1. Remove the 6” water gauge glass set from Part

Carton.

2. Install the gauge glass using the two ½” NPT

tappings to the right of the probe LWCO. See Figure

7 “Purpose of Tappings & Bosses”.

3. Thread the pressure gauge into 1/4” NPT tapping of

the front section. See Figure 7 “Purpose of Tappings

& Bosses”. Tighten with wrench applied to the

square shank of the gauge.

CAUTION

Do not apply pressure to gauge case, as this may

result in inaccurate readings.

O. FLOAT LwCO (MCDONNELL-MILLER #67),

AND GAUGE GLASS INSTALLATION.

1. Pre-assemble float-type LWCO per Figure 9 "Float-

Type LWCO and Gauge Glass Installation".

2. Install two ½” NPT x 2½" long Sch 40 brass nipples,

supplied loose inside Control Carton (disregard two

½" NPT x 1½" long brass nipples provided with

#67 LWCO package) and ½" NPT brass unions into

upper and lower front section tappings. See Table 3

"Purpose of Tappings & Bosses" and Figure 7.

3. Install water gauge glass on low water cut-off

assembly tee fittings.

4. Do not remove ¼” NPT plug factory installed on top

of #67 LWCO.

5. Insure that 3/8" NPT plug (provided within #67

LWCO package) is installed at bottom of #67

LWCO.

6. Remove #67 LWCO J-box cover.