Eic calibration, Entering operator calibration (mode 1), Setting the implement width – Buhler 535 User Manual

Page 70

435/485/535

3-4

EIC Calibration

Electronic Instrument Control System (EIC) -

Calibration

The EIC system is factory pre-calibrated with the

required operating presets and fault codes, however, it

is necessary to verify Mode calibration settings and

become familiar with the calibration procedure .

To access the Electronic Instrument Control System

for programming and calibration, follow the “Entering

Operator Calibration (Mode )” . All programming and

calibration is done with the key switch in the “RUN”

position and the engine off .

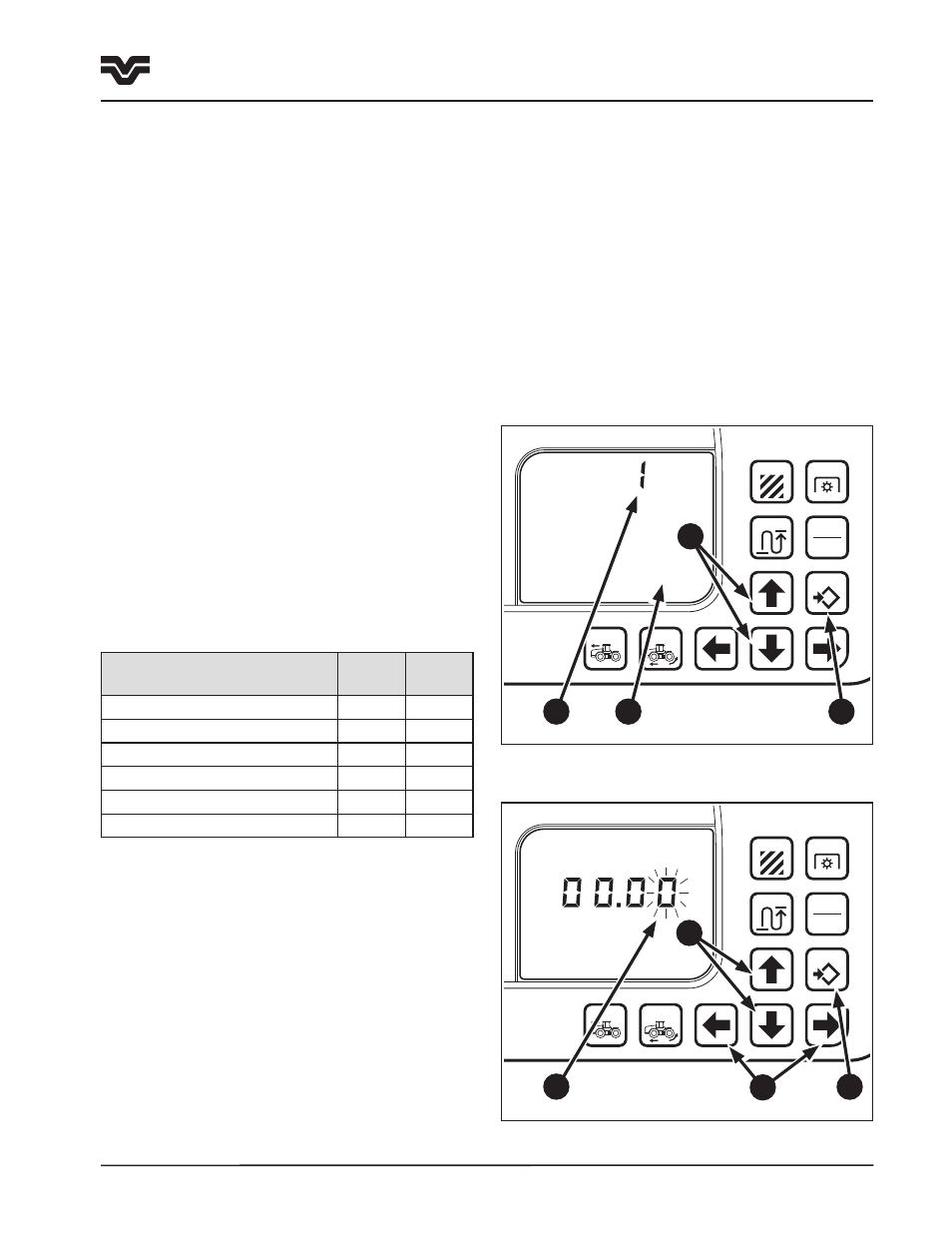

Entering Operator Calibration (Mode 1)

. Hold the SELECT button () for two seconds

2 . The TPM will display “” (2) and “CAL (3) .” (If it

does not, use UP and DOWN arrow button (4) to

change the display to “”)

3 . Hold the SELECT button () for two seconds to enter

into mode (Operator Calibration)

4 . Touch the SELECT button () to cycle through the

six Operator Calibration screens:

1. Setting the implement width

The implement width is used in all area calculations

performed by the TPM . It is a measure of the working

width of the implement .

. Enter the width of the implement . The selected

(flashing) digit (5) can be changed by touching

the UP and DOWN arrow buttons (4) . Other digits may

be selected by touching the LEFT and RIGHT arrow

buttons (6) .

2 . Once the implement width has been entered, touch

the SELECT button () to confirm the change .

Section 3 - Operation

EIC - Calibration

F3-122

SPEED

PTO RPM

AREA

START

STOP

CAL

% SLIP

DISTANCE

SELECT

1

2

3

4

Calibration Screen

Without

TPM

With

TPM

Implement width

Slip percent threshold

-

2

Service alert/intervals

3

3

Area preset

4

4

Fault code display on/off

5

5

English/Metric units selection

6

6

F3-123

SPEED

PTO RPM

AREA

START

STOP

IMP WIDTH CAL

% SLIP

DISTANCE

SELECT

4

5

6

1