Buhler 535 User Manual

Page 160

435/485/535

4-27

F4-69

F4-68

F4-32

Operation 32

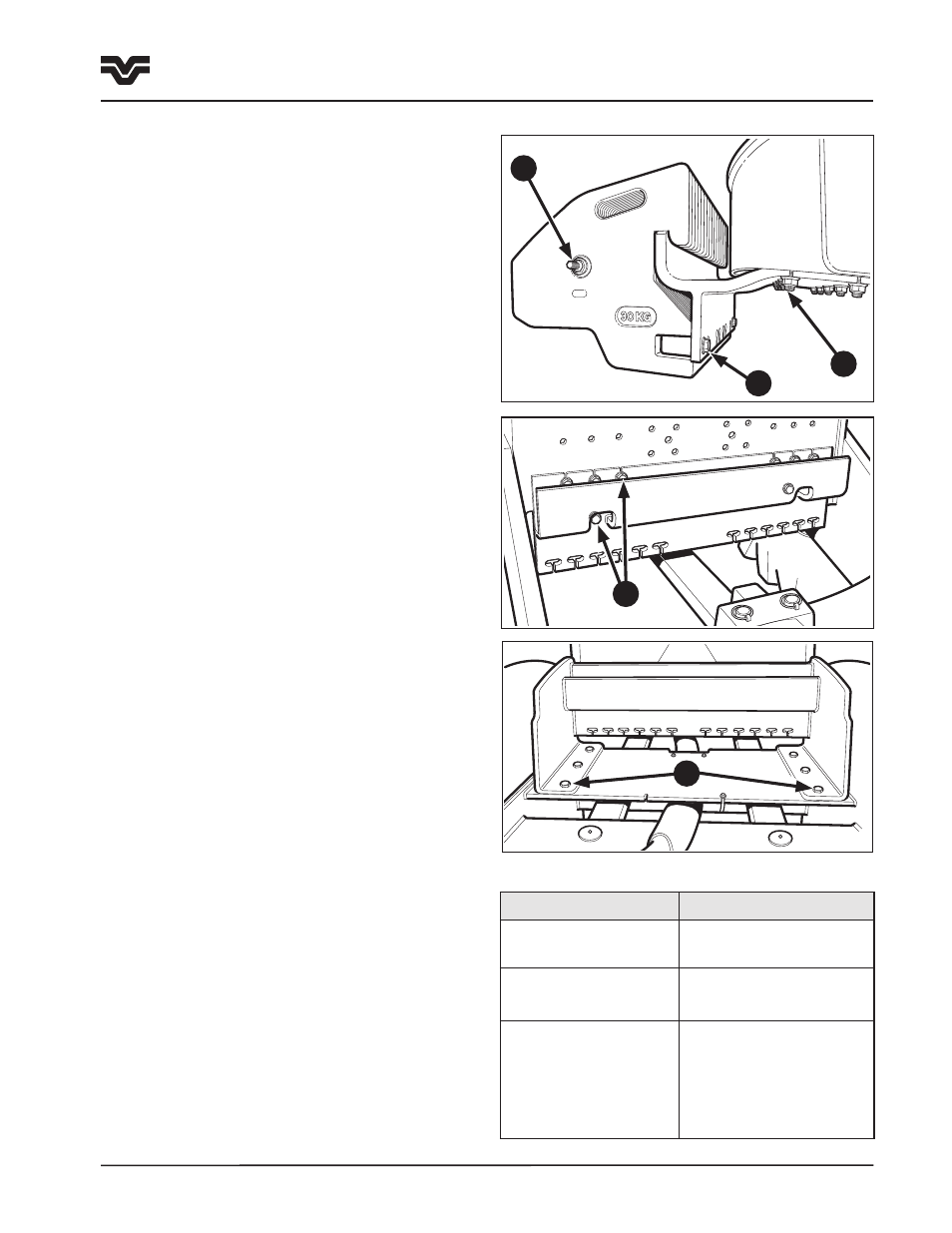

Check the Weight Kit (Optional) Hardware Torques

Check the hardware securing the front, upper rear and

rear weight brackets and weights to the tractor .

Front weight kit - Check the ten flanged nuts ()

securing the bracket to the tractor and torque to

633 N·m (467 ft-lbs) .

Check the weight mounting bolts (2) securing the

weights to the weight bracket and torque to 480 N·m

(354 ft-lbs) .

Check the tie rod nuts (3) and torque to 633 N·m

(467 ft-lbs) .

Rear weight kit

Check the eight bolts (4) securing the bracket to the

tractor and torque to 633 N·m (467 ft-lbs) .

The rear weights are mounted using the same

procedure as the front weight kit . Check the weight

mounting bolts (2) securing the weights to the weight

bracket and torque to 480 N·m (354 ft-lbs) .

Check the tie rod nuts (3) and torque to 633 N·m

(467 ft-lbs) .

Upper rear weight kit (not shown)

Check the six bolts (5) securing the bracket to the

tractor and torque to 633 N·m (467 ft-lbs) .

The upper rear weights are mounted using the

same procedure as the front weight kit . Check the

weight mounting nuts (2) securing the weights

to the weight bracket and torque to 480 N·m

(354 ft-lbs) .

Check the tie rod nuts (3) and torque to 633 N·m

(467 ft-lbs) .

Wrench size: 30 mm

Operation 33

Check the Wheel Hardware Torque

All wheel mounting hardware must be checked for

proper torque . The following chart shows wheel

torques, based on wheel configuration .

Wrench size: 30 mm

NOTE: For identification of particular hardware

components, see Operation 75 later in this section.

1

3

2

Configuration

Torques

Singles

Wheel to Hub Nuts

70 N·m (525 ft-lbs .)

Standard and Special

Row Crop Drum Duals

Wheel to Hub Nuts

70 N·m (525 ft-lbs .)

Drum Style Triples

Wheel to Hub Nuts

70 N·m (525 ft-lbs .)

Center Wheel to Outer

Wheel Nuts

70 N·m (525 ft-lbs .)

Section 4 - Lubrication & Maintenance

Every 250 Hours

4

5