Routine care and adjustment, Cleaning, Øïlí aãlíací cøæïlï – Brady 200M-e 300 User Manual

Page 73: Ohdqlqj

Bradyprinter 200M-e and 200M-e 300 User’s Guide

63

/ØÏlÍ AÃlÍAcÍ cØÆÏlÏ

&OHDQLQJ

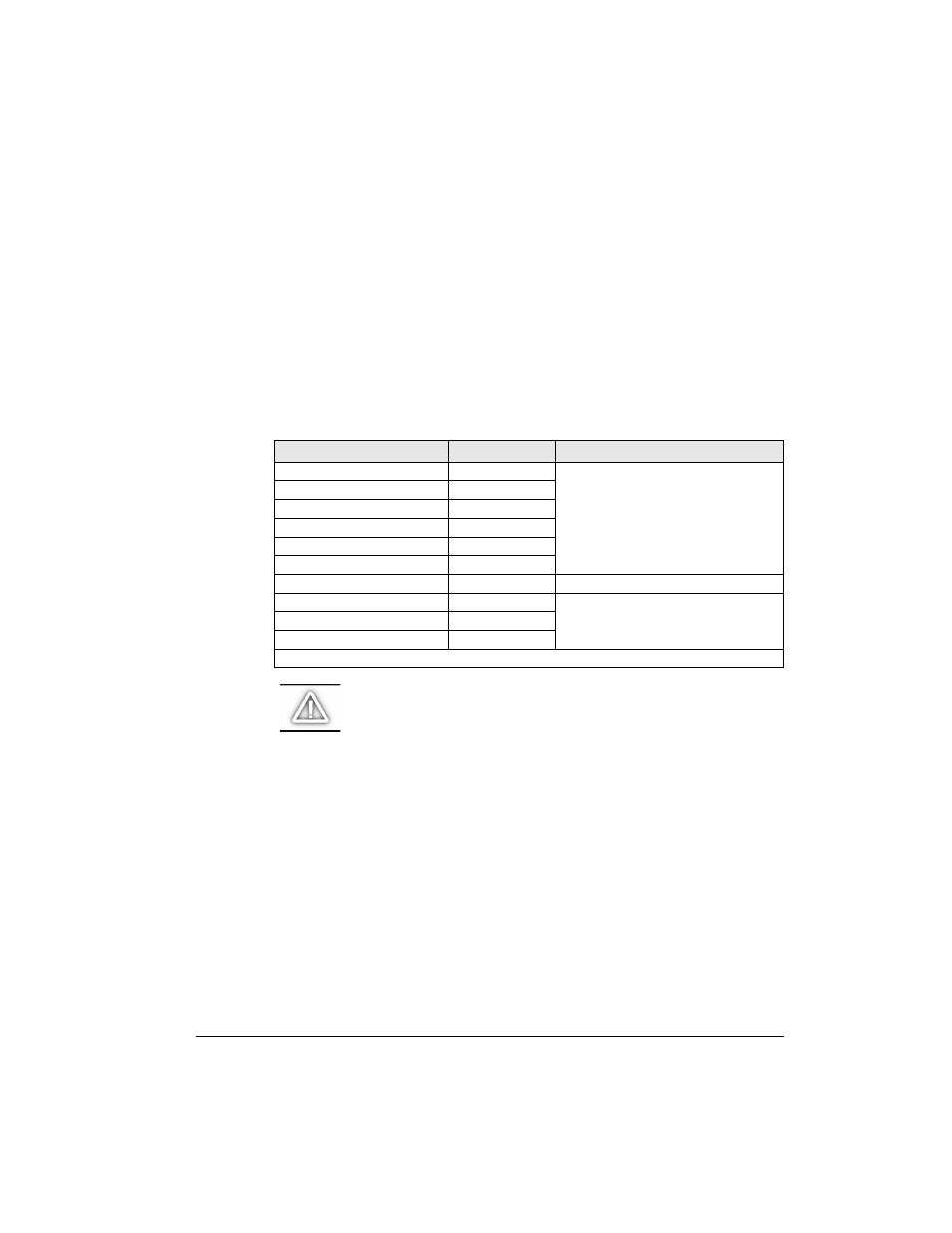

Table 2 provides a brief cleaning schedule. Specific cleaning procedures

are provided on the following pages.

CAUTION: Use only the cleaning agents indicated. Brady

Corporation will not be responsible for any other fluids being

used on this printer.

Table 2

Area

Method

Interval

Printhead

Solvent*

Direct thermal print mode:

After every roll of media (or

500’/152 m of fanfold media).

Thermal transfer print mode:

After every roll of ribbon.

Platen roller

Solvent*

Transmissive sensor

Air blow

Black mark sensor

Air blow

Media path

Solvent*

Ribbon sensor

Air blow

Label available sensors

Air blow

Monthly

Tear-off/peel-off bar

Solvent*

As needed

Snap plate

Solvent*

Cutter

Solvent*

* Brady recommends using a solvent containing 90% isopropyl alcohol.