3 design process, 1 operating parameters, An372 – Cirrus Logic AN372 User Manual

Page 4: Output power p, Ac line input voltage v, Output voltage v, Load current i, Maximum switching frequency, Increasing f

AN372

4

AN372REV1

3 Design Process

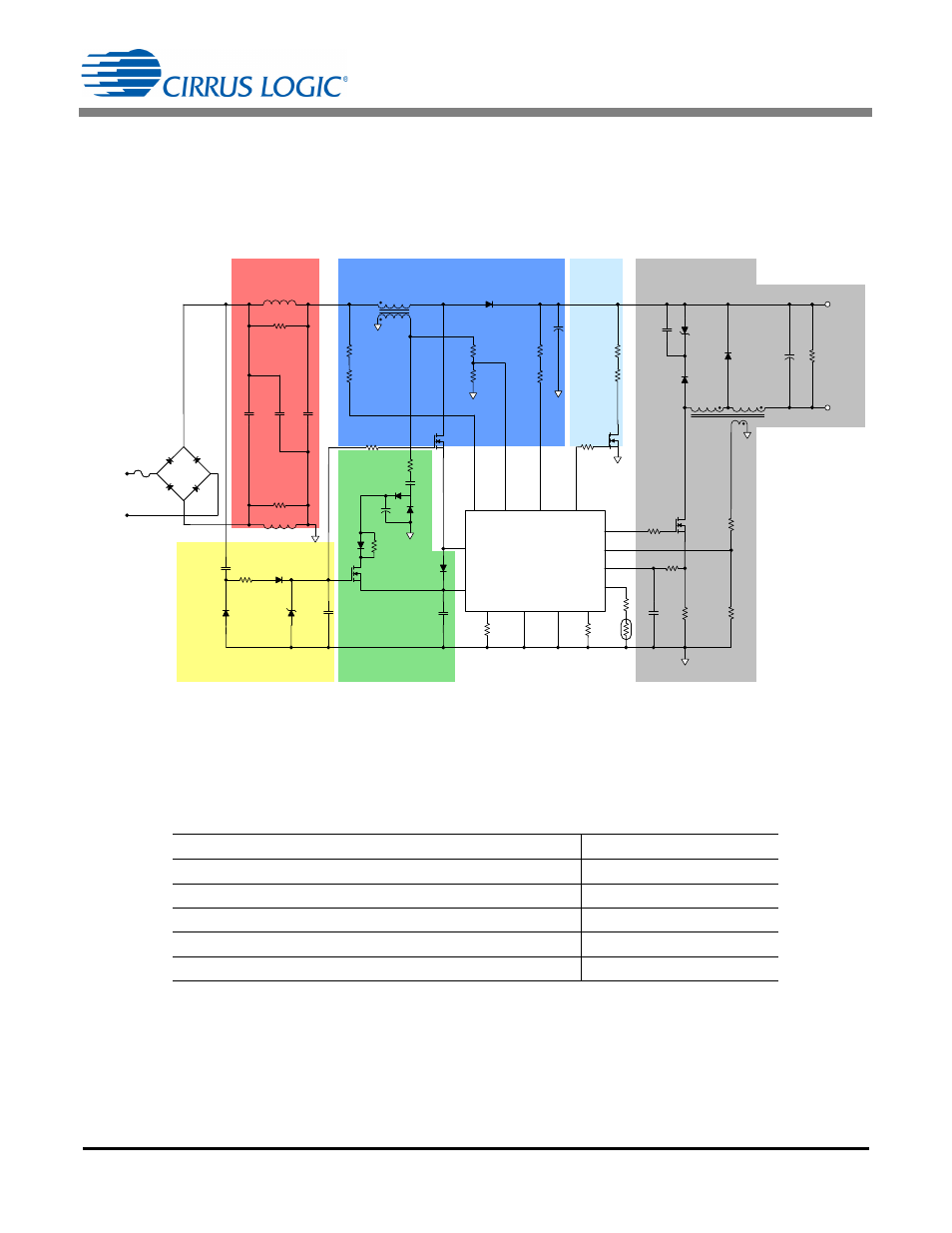

The design process for a two-stage power converter system can be partitioned into six circuit blocks (see Figure 1).

The AC line voltage is passed through an electromagnetic interference (EMI) filter to suppress conducted interfer-

ence found on the power line. The output of the EMI filter is then converted to the desired DC output by a boost-buck

converter. The power converter system includes the Gate Bias, Steady State Supply, and Active Clamp support cir-

cuitry.

3.1 Operating Parameters

To initiate the design procedure, a set of operating parameters is required. Operating parameters required for

the analytical process are outlined in the table below. Parameters critical to the overall design, but not

specifically addressed in this document, include: EMI compliance, efficiency, footprint, layout, and operating

temperature.

Parameters

Symbol

Output Power

P

OUT

AC Line Input Voltage

V

IN

Output Voltage

V

OUT

Load Current

I

OUT

Maximum Switching Frequency

*

F

SW(max)

* Increasing F

SW

may reduce the size of the magnetics but increases switching losses in the FET.

LED +

LED -

L1

L3

R8

R11

R3

R7

R1

R2

Q3

L2

Z1

C2

D7

D6

Q1

R17

R13

Q2

D5

R18

NTC

R14

R15

R22

R23

Q4

R21

R19

R9

BR1

F1

R12

D8

R4

CS1612 /13

FBGAIN

IAC

FBAUX

BSTOUT

GND

SGND

IPK

CLAMP

GD

FBSENSE

eOTP

VDD

SOURCE

L

N

AC Mains

D4

R10

R16

R6

R20

R5

D1

BSTAUX

R24

Boost

Gate Bias

Steady State

Supply

Active

Clamp

Second Stage

Buck

EMI

C8

C10

C9

C7

C6

C5

C4

C3

C1

C12

L4

D3

D2

C11

Z2

Figure 1. Block Diagram of CS1612/13 Design