2 boost stage design steps, An372 – Cirrus Logic AN372 User Manual

Page 28

AN372

28

AN372REV1

Step 13) Buck Inductor Specification

Specifications for the buck inductor L4 can now be compiled to enable suppliers to design within size and cost

constraints.

Step 14) Circuit Adjustments

Now that the inductor has been defined and built, it may need to be adjusted. For more information, see Circuit

Adjustments on page 15.

Validate that the system meets the operating criteria. This may require adjusting components like R

Sense

and

R

FBGAIN

. For more information, see Recalculate R

4.2 Boost Stage Design Steps

Using Equation 23, calculate I

PK(BST)

:

Using Equation 24, calculate R

IPK

:

Step 17) Boost Inductor Specifications

Use Figure 10 in the Boost Inductor Specifications section on page 19 to determine the boost value of the

boost inductance. Choosing a maximum switching frequency of 110kHz, find the intersection with the 230V

maximum switching curve, and get the corresponding power. This is 50 Watt

mH, the constant (P

IN

L

BST

),

for this frequency and voltage. Dividing by the input power, obtain the inductor value.

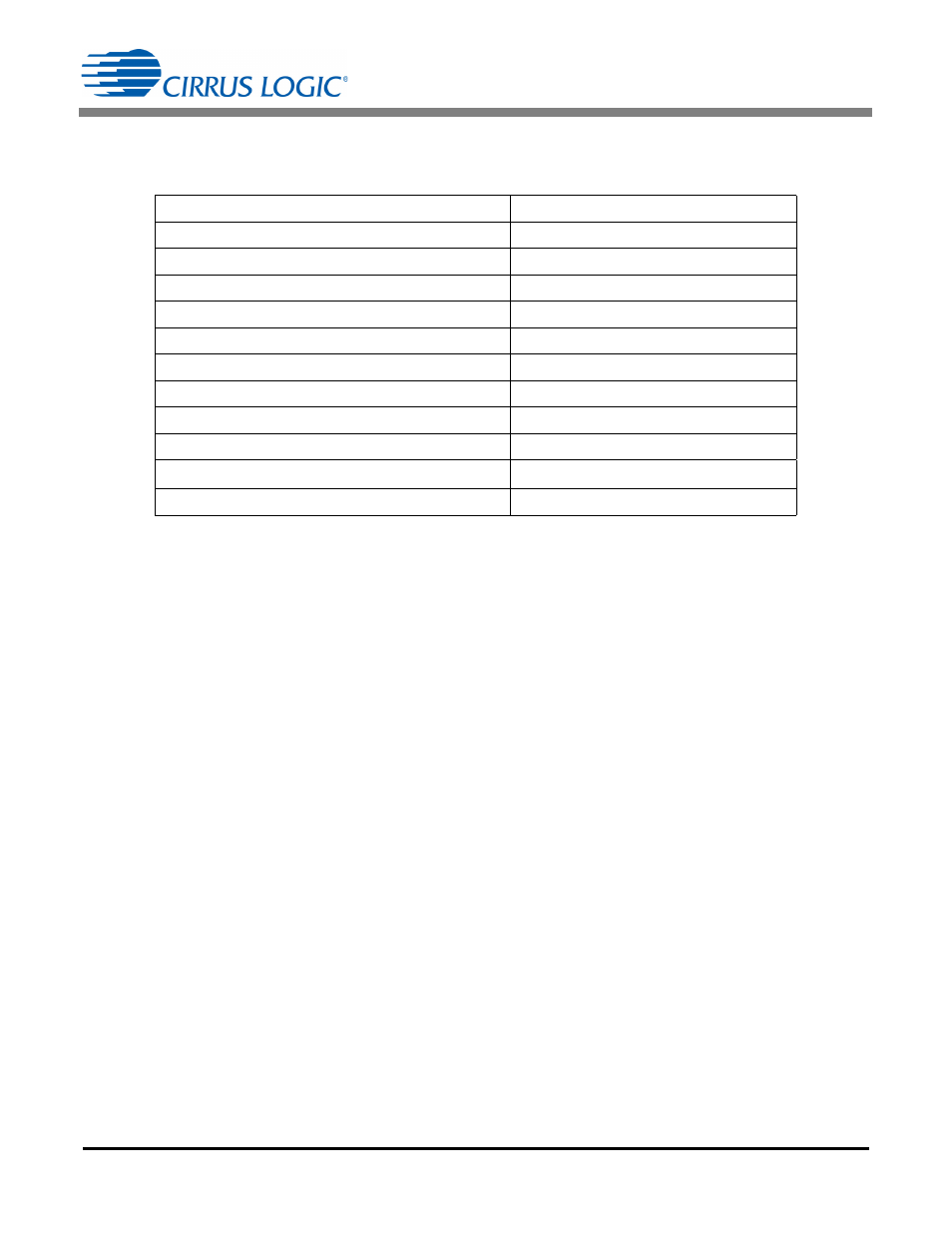

Parameter

Value

Output DC Power

10.1W

Converter Topology

CRM Buck

Switching Frequency

125kHz

Primary Inductance

3.8 mH

10%

Peak Current in the (N+1) Turn Winding

0.207A

RMS Current in the N-turn Winding

62mA

Turn Ratio N:1

4

RMS Current in the 1-turn Winding

0.511A

Leakage Inductance with 1-turn Winding Shorted

<50

H

Auxiliary Winding Turn Ratio (N/N

AUX

)

20

Auxiliary Wire

Any convenient gauge

I

PK BST

3.64 P

IN

V

RMS

---------------------------

3.64 10.1W

230V

-----------------------------------

160mA

=

=

=

[Eq. 60]

R

IPK

15.625 10

3

V

I

PK BST

-------------------------------------------

15.625 10

3

V

160mA

-------------------------------------------

97.6k

=

=

=

[Eq. 61]

L

BST

50WmH

P

IN

----------------------

50WmH

10.1W

----------------------

5mH

=

=

=

[Eq. 62]