Setup configuration, 5 volume dispensed, 6 resuming when paused – Next Advance SP1800 User Manual

Page 19: 7 pump stalled

NEXT>>>ADVANCE

www.nextadvance.com

SP1600/1800 Programmable Syringe Pump

Publication #1200-02

14

9/15/04

in the current Program Phase. Also changing the pumping direction changes the accumulated “Volume

Dispensed” according to the new pumping direction.

6.5 Volume Dispensed

While pumping, the display will show the total accumulated volume pumped with the ‘ml’ or ‘

l’ LED lit

and the ‘Dispensed’ LED lit. Volume is computed based upon the syringe inside diameter setting.

The volume is accumulated separately for infusion and withdrawal. When the pump changes direction,

the “Volume Dispensed” changes to the accumulated volume of the pumping direction.

The “Volume Dispensed” accumulations for infusion and withdrawal are reset to 0 when:

A) The pump is powered on.

B) The syringe diameter is changed.

C) From the RS-232 clear “Volume Dispensed” command (CLD).

D) Volume Dispensed rolls over from 9999 to 0.

When the Pumping Program is stopped, and the display shows the Program function or pumping rate

information, the accumulated Volume Dispensed can be displayed by pressing the ‘Volume’ key one, two,

or three times, depending on the current display.

6.6 Resuming When Paused

If the Pumping Program is stopped before the completion of the Pumping Program, the ‘Pumping’ LED

will blink, indicating that the Pumping Program is paused. While the ‘Pumping’ LED is blinking, starting

the pump again will resume the Pumping Program where it was stopped. This means that the Pumping

Program will continue at the point in the Phase where it was stopped and the ‘Volume to be Dispensed’

will still be referenced from when the Program Phase first started.

Pressing any key other than the ‘Start’ key will cancel “Pumping Program paused” and the ‘Pumping’

LED will stop blinking. When the Pumping Program is started again, it will start from the beginning

(Phase 1).

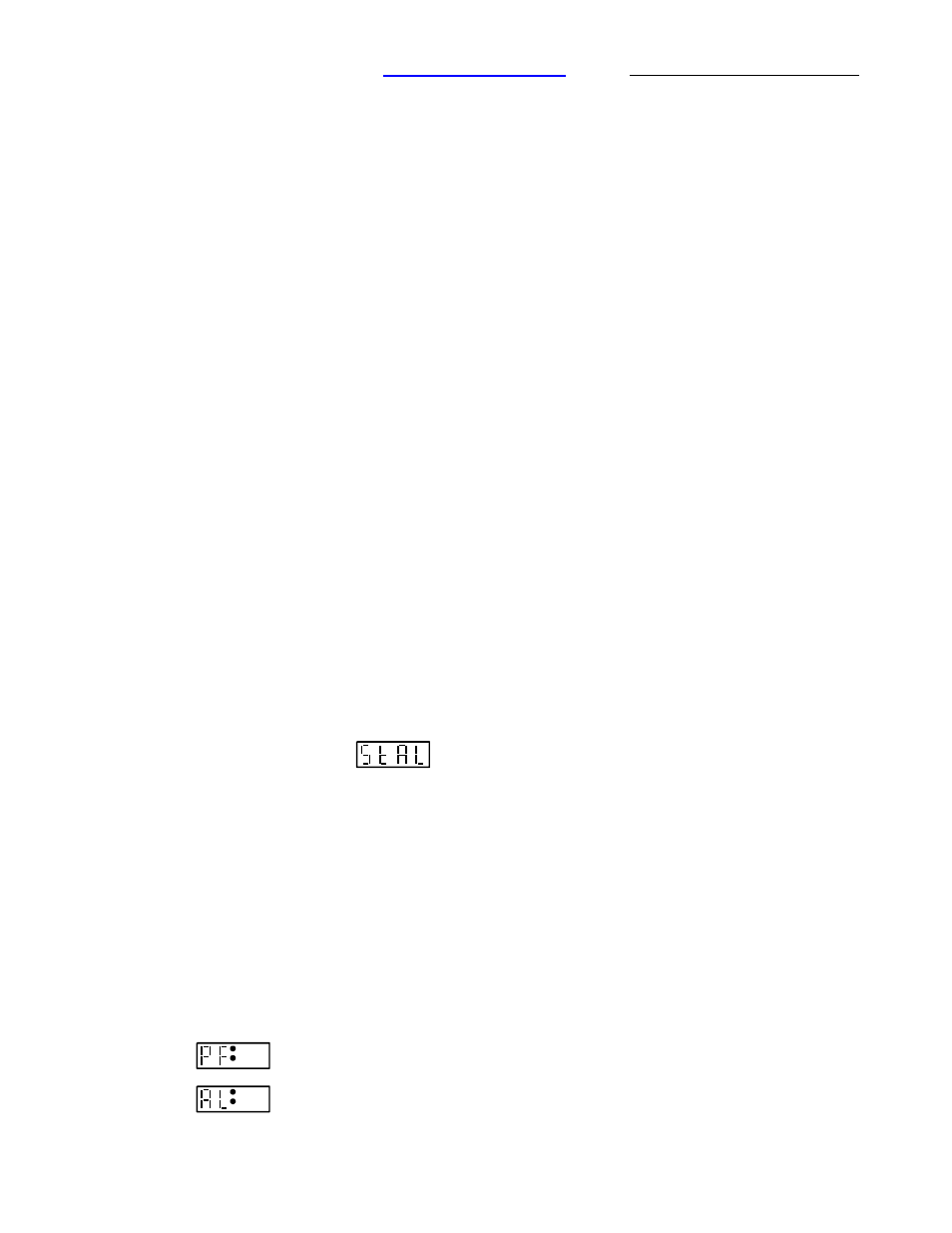

6.7 Pump Stalled

When the operation of the motor is impeded due to excessive force needed to drive the syringe, or when

then collar clamp position is reached, the pump will stop, pausing the Pumping Program, and a stall alarm

will occur. The display will show

, the ‘Pumping’ LED will blink, and the buzzer will sound

continuously if alarms are enabled. Also, if the RS-232 Safe Mode is enabled, an auto-alarm message will

be sent to an attached computer.

Pressing any key will stop the buzzer and clear the alarm. When the problem causing the pump motor to

stall has been corrected, the Pumping Program can be resumed by any start trigger, the ‘Start’/’Stop’ key,

TTL input, or RS-232.

7. Setup Configuration

To change or view the setup configuration, the Pumping Program must be stopped. Press the

‘Diameter’/‘Setup’ key until the first parameter, ‘PF’ is displayed. After 2 seconds, or when any non-

arrow key is pressed, the next parameter will be displayed (see sec. 5.12, ‘Setup’ ). Pressing an arrow key

under a value will increment, select, or scroll through the valid values for the parameter. The Setup

Configurations will be displayed in the following order:

n

Power Failure mode, where ‘n’ is the current setting.

n

Alarm mode, where ‘n’ is the current setting.