Ttl i/o operational controls, Next>>>advance – Next Advance SP1070-M User Manual

Page 53

NEXT>>>ADVANCE

www.nextadvance.com

SP1000 series operator’s manual

Manual SP1000 series

46

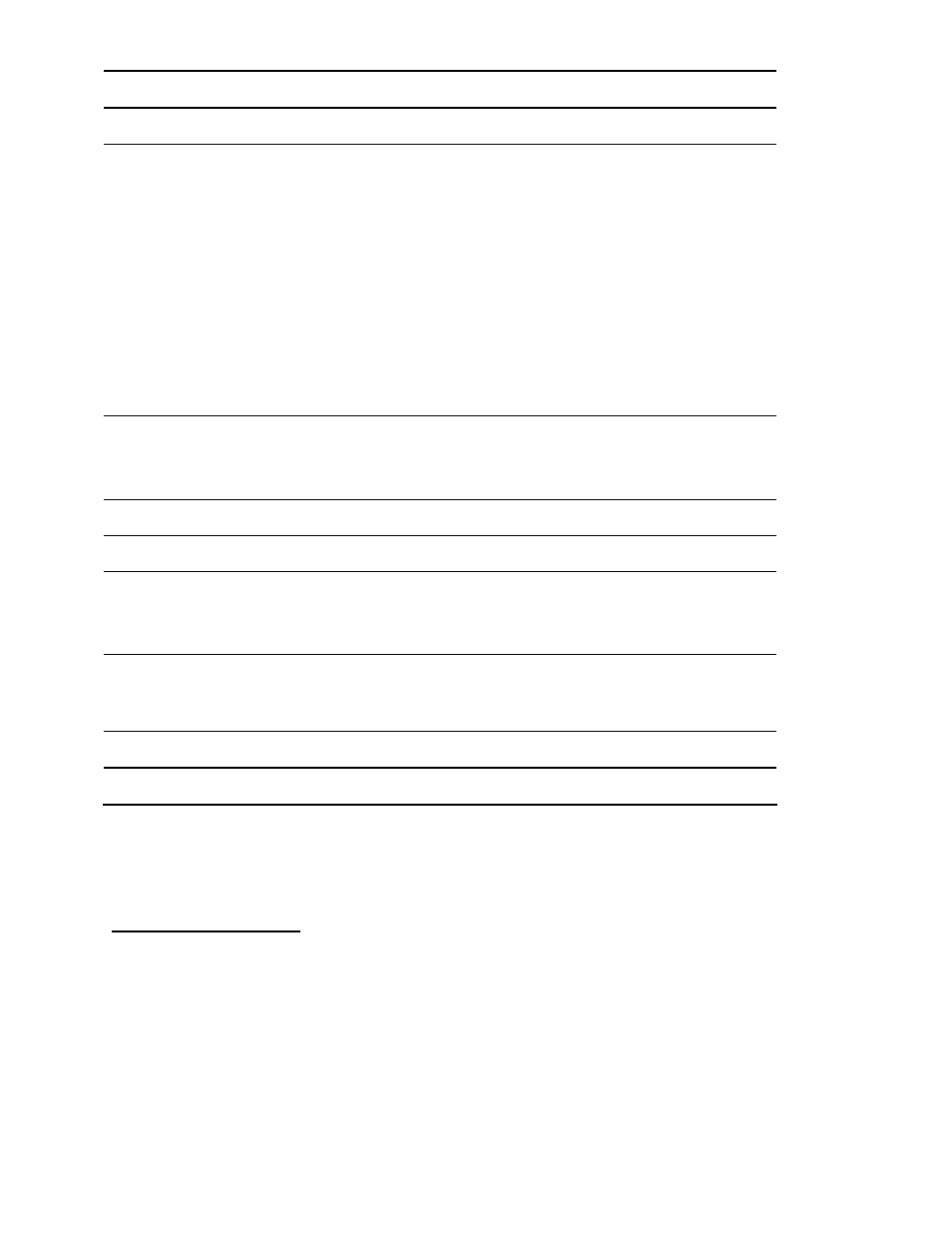

Pin #

Definition

Type

Function

1

Vcc (5V)

Reference

Logic high reference. Power on indicator.

2

Operational Trigger

Input

Configurable start/stop operational trigger input.

[Ft] Foot Switch

Falling edge: Start or stop trigger

[FH] Foot Switch Hold

Falling edge: Start trigger

Rising edge: Stop trigger

[F2] Foot Switch Reverse Rising edge: Start or stop trigger

[LE] Level

Falling edge: Stop trigger

Rising edge: Start trigger

[St] Start only

Falling edge: Start trigger

[t2] Start only Reverse

Rising edge: Start trigger

[SP] Stop only

Falling edge: Stop trigger

[P2] Stop only Reverse

Rising edge: Stop trigger

[rL] Start on low level

Low level:

Start trigger

[rH] Start on high level

High level:

Start trigger

[SL] Stop on low level

Low level:

Stop trigger

[SH] Stop on high level

High level:

Stop trigger

[Et] Program function: redirect trigger to Event trap

3

Pumping Direction

Input

Changes pumping direction according to setup

[dr:rE]

[dr:dU]

Falling edge: Infuse

Withdraw

Rising edge: Withdraw

Infuse

4

Event Trigger

Input

Event input or user definable input

5

Program Output

Output

Program controlled output or user definable output

6

Program Input

Input

Program conditional input read by the “IF” program function.

Also user definable input.

Also used by the keypad lockout function.

7

Pump Motor Operating

Output

[RUN.0] High: Pumping; Low: Not pumping

[RUN.1] High: Pumping or Pause timer

Low: Pumping Programmed stopped or paused

8

Pumping Direction

Output

High: Infuse; Low: Withdraw

9

Ground (0V)

Reference

Logic low reference

11.1

TTL I/O Operational Controls

While the user is changing settings or configuration from the keypad, external control by the ‘Pumping

Direction’ and ‘Operational Trigger’ inputs will be ignored. These controls will also be ignored if an alarm

condition exists.

Operational Trigger (Pin 2): The input signal on this pin controls the operation of the Pumping Program.

Its functionality is user configurable. Use the ‘TR:nn’ Setup Default Configuration to configure this input

pin (See Section 8.4, TTL I/O Operational Trigger Default Configuration).

Each option defines when the Operational Trigger input is activated. When activated, the trigger emulates

the ‘Start/Stop’ key:

Foot Switch:

Operates like the ‘Start/Stop’ key, whereby each falling edge (contact to ground) either

starts or stops/pauses the Pumping Program.

Foot Switch Hold: Falling edge starts the Pumping Program and the rising edge stops the Pumping

Program. With a foot switch, the Pumping Program will run while the foot switch was

held down.