WIKA HP-2 User Manual

Page 11

11

WIKA operating instructions pressure transmitter, model HP-2

11379180.03 09/2013 GB/D/F/E

GB

6. Commissioning, operation

6. Commissioning, operation

CAUTION!

Prior to commissioning, the pressure transmitter must be subjected to a

visual inspection.

Only use the pressure transmitter if it is in perfect condition with respect to

safety.

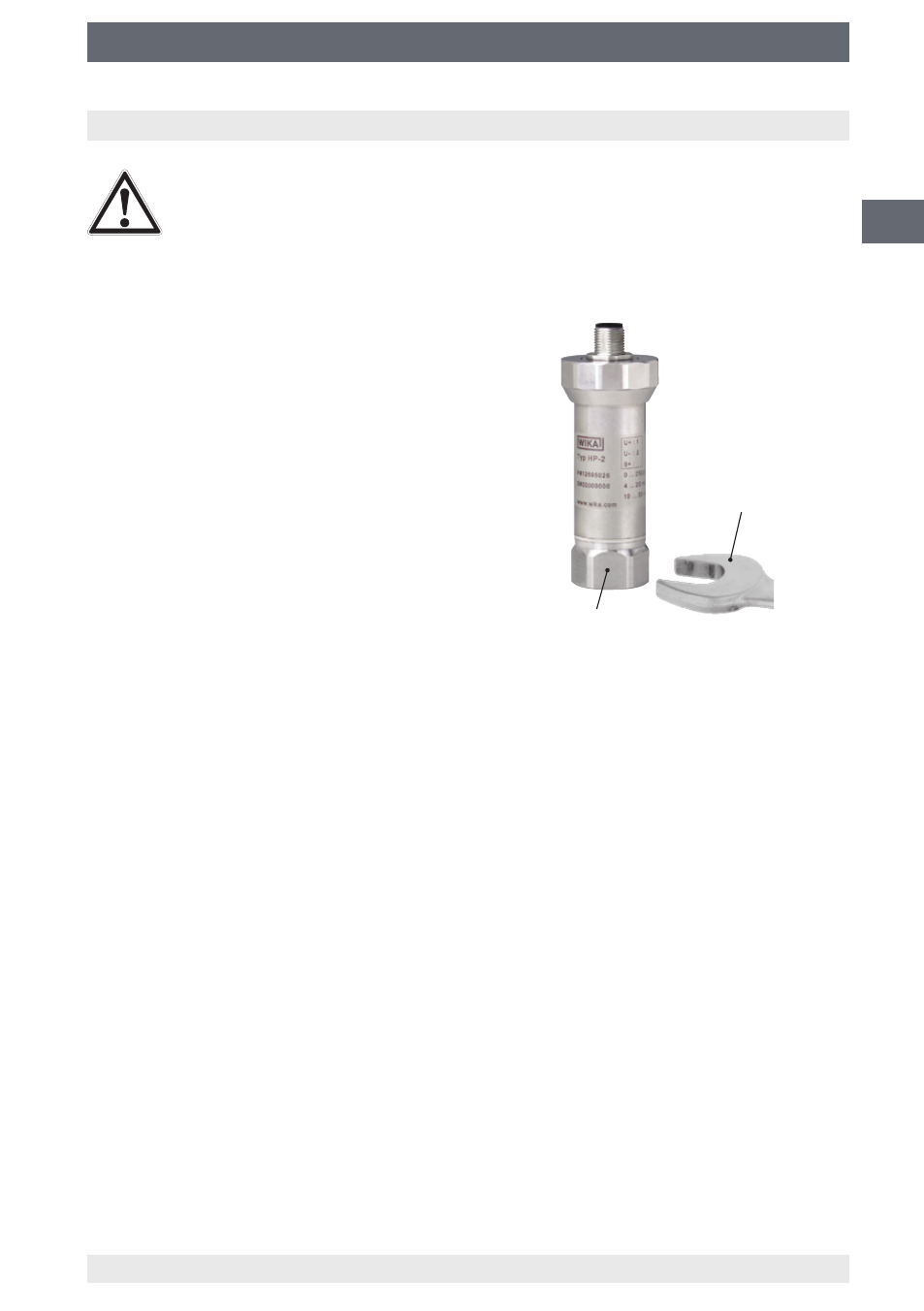

6.1 Mechanical mounting

■

The sealing faces at the instrument have to be

undamaged and clean.

■

When screwing the instrument in, the force

required to do this must not be applied through

the case, but only through the spanner flats

provided for this purpose and using a suitable

tool.

For the installation point, the valid values for

tightening torque and maximum pressure

should be taken from the high-pressure pipe

supplier's documentation.

■

When screwing in, do not cross the threads.

■

For information on tapped holes and welding sockets, see Technical information

IN 00.14 at www.wika.com.

6.2 Electrical mounting

■

The instrument must be grounded via the process connection.

■

Use the pressure transmitter with shielded cable, and ground the shield on at least

one end of the lead, if the lines are longer than 30 m (3- or 4-wire) or leave the build-

ing.

■

Select a cable diameter that matches the cable gland of the plug. Make sure that

the cable gland of the mounted plug has a tight fit and that the seals are present and

undamaged. Tighten the threaded connection and check that the seal is correctly

seated, in order to ensure the ingress protection.

■

For cable outlets, make sure that no moisture enters at the cable end.

■

Observe the specifications in accordance with chapter 3 “Specifications”.

Spanner flats

Open-ended spanner

(spanner width 27)