11 troubleshooting – Festo Электроцилиндр ESBF User Manual

Page 23

ESBF-BS

Festo – ESBF-BS – 1201NH English

23

11

Troubleshooting

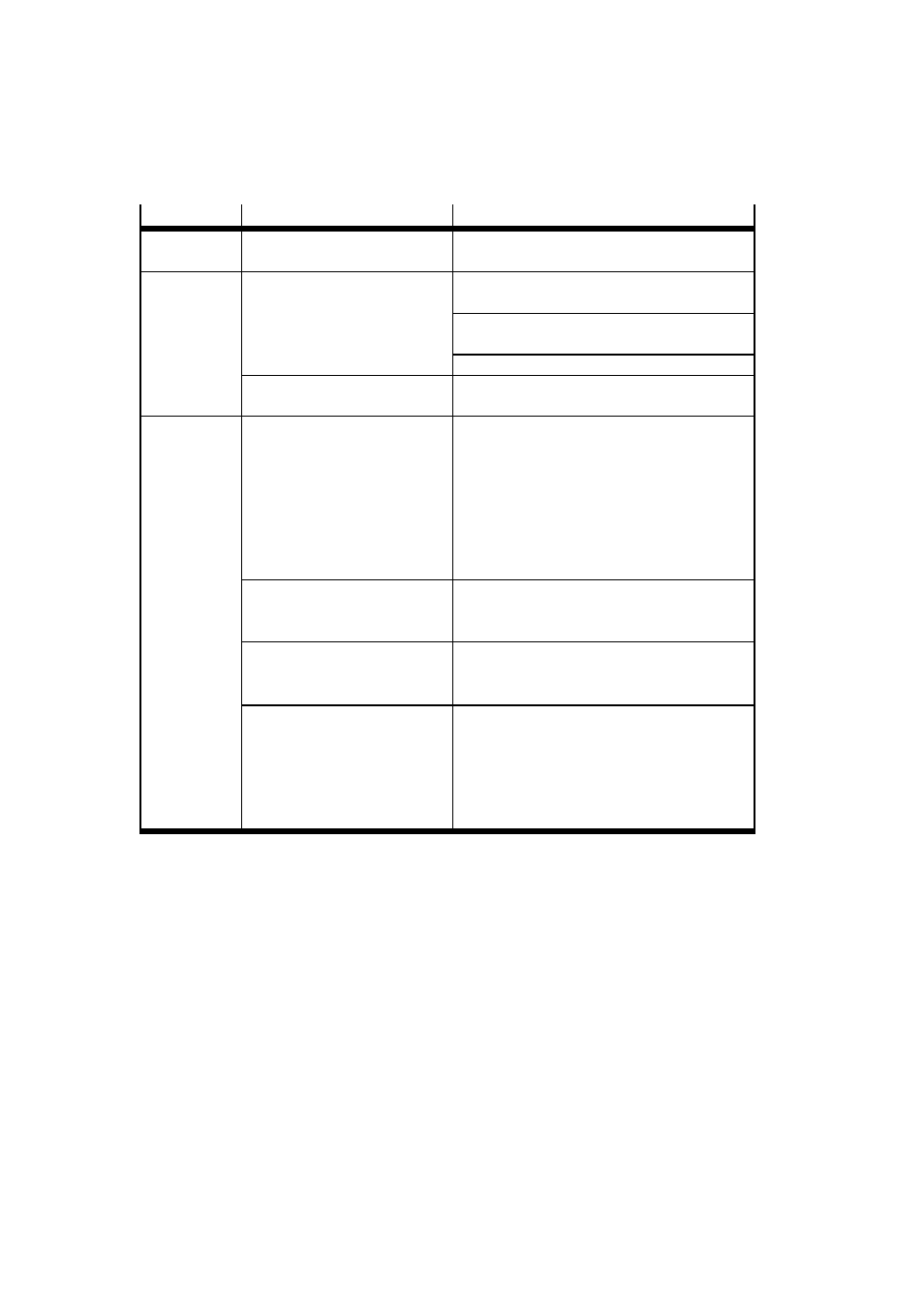

Malfunction

Possible cause

Remedy

Axial play too

large

Wear

Send the ESBF to Festo for repairs

Running

noises or

vibrations

Tension

Install ESBF so it is free of tension

(evenness of the bearing surface: ≤ 0.2 mm)

Lubricate the piston rod (

8 Maintenance and

care)

Modify travel speed

Incorrect regulator settings

Change the regulator parameters

(only with servo motors)

Piston rod

does not move

Jamming in mechanical end posi-

tion (e.g. after homing at too

high a speed or after improper

travel into an end position during

operation)

–

To release a jam manually:

1. Switch off power,

2. Remove motor and coupling housing,

3. Turn drive shaft to release it

–

Reduce speed for reference travel

–

Set software end positions at least 0.25 mm

away from the mechanical end positions

(the stops)

Loads too high

–

Reduce effective load

–

Reduce travel speed

–

Send the ESBF to Festo for repairs

When using the parallel kit, the

pretension on the toothed belt is

too high

Reduce the pretension on the toothed belt

(

assembly instructions for the parallel kit)

Ambient temperature too low

(increased breakaway torque in

initial run due to increasing vis-

cosity of the lubricants in the

spindle system)

–

Reduce effective load

–

Reduce travel speed

–

In the case of servo motors, it may be neces-

sary to allow higher peak current

(

operating instructions for the motor)

–

Adjust ambient temperature

Tab. 4