Festo Электроцилиндр ESBF User Manual

Page 18

ESBF-BS

18

Festo – ESBF-BS – 1201NH English

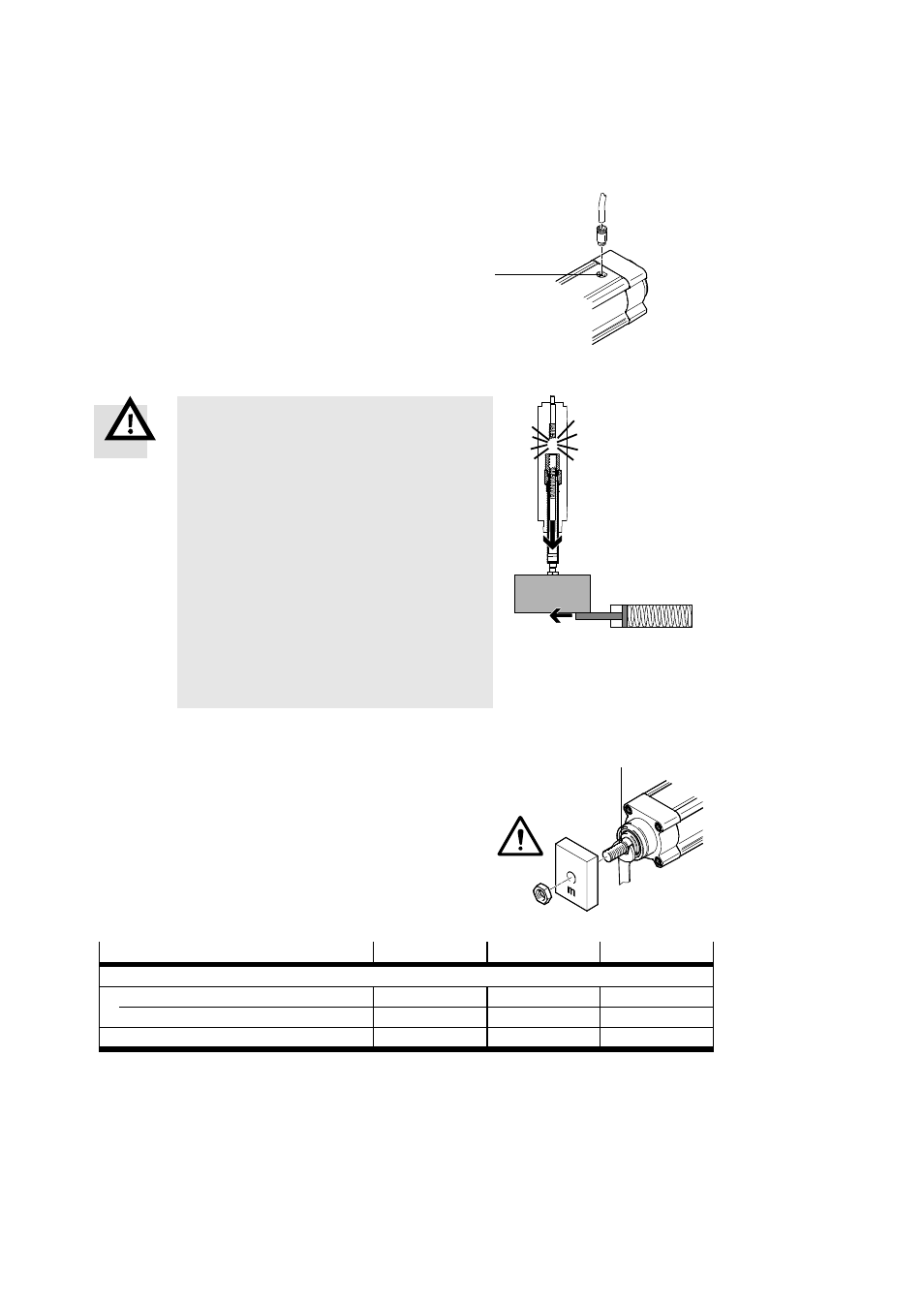

Pressurising and exhausting the pressure compensation opening for variant ESBF-...-S1/F1:

•

Screw a G1/8 fitting into the thread

4.

•

Use a tube for the supply and exhaust of fresh air.

The exhausting process should be conducted in a protected

area (free from dust and moisture) or in a large pressure

reservoir. Alternatively, a slight excess pressure

(max. 0.2 bar) can be applied as sealing air.

Fig. 5

4

Fitting in a vertical or sloping position:

Warning

Uncontrolled moving masses can cause personal

injury and material damage (risk of crushing).

If there is a spindle nut fracture inside the ESBF or

a toothed belt breaks

when using parallel kit EAMM-U (e.g. due to wear),

the effective load will fall down.

•

Check whether additional external safety

measures against damage are required

(e.g. toothed latches or moveable bolts). In this

way you can prevent the work mass from slid-

ing down.

•

Examine the toothed belt of the parallel kit reg-

ularly for wear

(

assembly instructions for the parallel kit).

Fig. 6

Installing the effective load

•

Place the centre of gravity of the effective load, if possible,

centrally to the piston rod.

•

When securing the effective load make sure that no torque

is transferred to the piston rod.

The wrench flat

7 can be used to exert counter pressure.

•

Secure the effective load to the piston rod.

The piston rod will bend depending on the effective load

(

Appendix 13 Characteristic curves).

7

Fig. 7

Size

63

80

100

Piston rod thread

Male thread

M16x 1.5

M20x1.5

M20x1.5

Female thread

M10

M12

M12

Width across flats

7

ß

[mm]

17

22

22

Tab. 2