I n s t r u c t i o n s e t, Calculation of the microstep-frequency, 2 calculation of the microstep-frequency – RMS Technologies 4-AXIS CONTROLLER/DRIVER User Manual

Page 20: Vclkdiv f f, Full step frequency=1/16 microstep frequency • f

20

S I X P A C K / Q U A D P A C K

Trinamic Motion Control GmbH & Co KG

Sternstraße 67

D – 20357 Hamburg, Germany

Phone +49-40-51 48 06 - 0

FAX: +49-40-51 48 06 - 60

http://www.trinamic.com

8 I N S T R U C T I O N S E T

The instruction code is listed in hexadecimal notation, prefixed with $-sign. “motnr“ substitutes the

number of the motor (0=motornr.1 ... 5=motornr.6). Parameters with more than 1 byte are to be

transmitted with the least significant byte (bit 0 – 7) first.

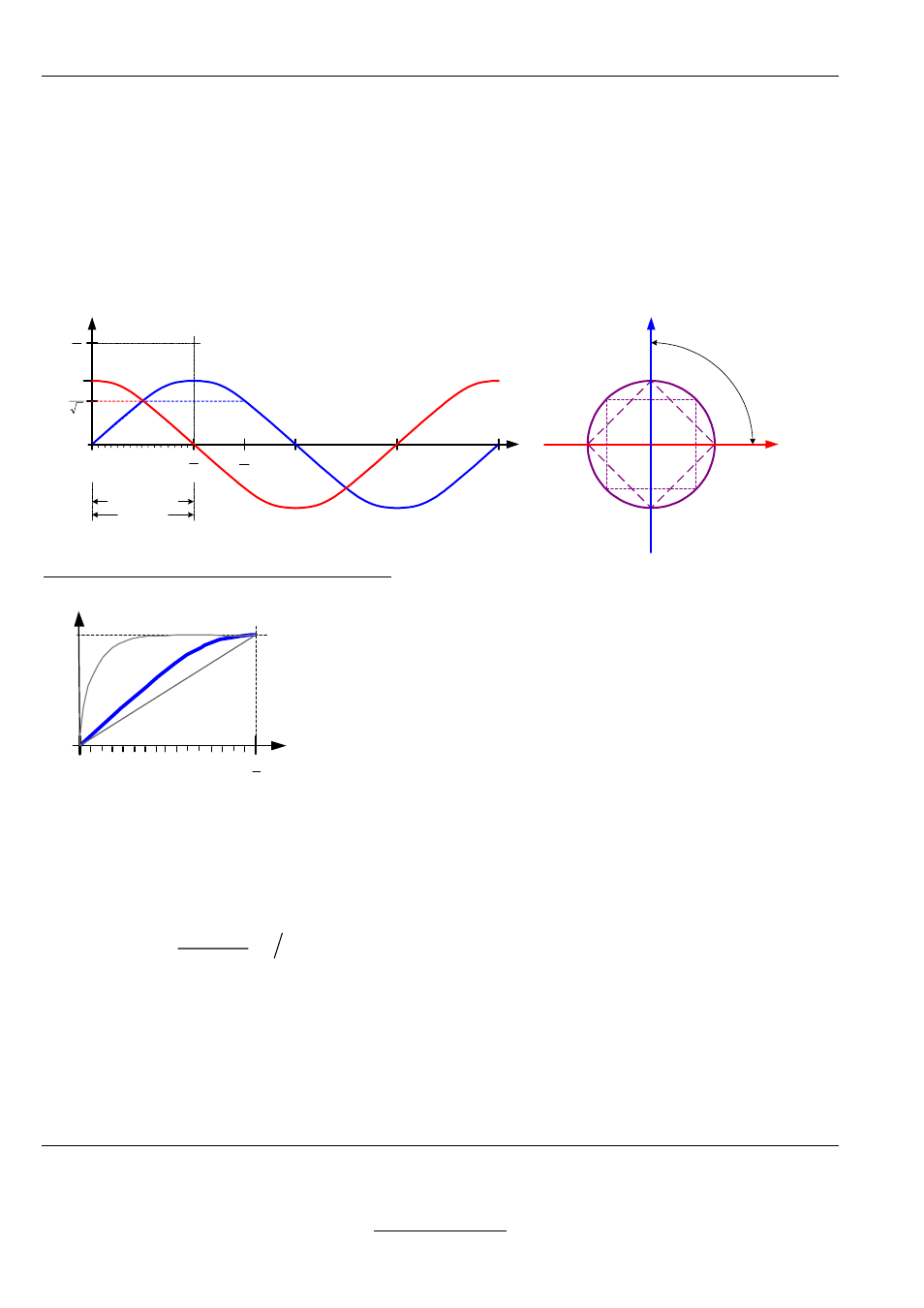

8.1 Adapting the microstep-table to the motor characteristics

alternative motor characteristics (s. CMD $17)

Most motors have varying microstep lengths, due

to this the motor would drive discontinuously for a

sin -/ cos -current. In order to reach a smoother

run, you can drive the motor with an adjusted

current, so that the motor’s characteristics can be

compensated. This current curves are generated

with the 16 values in the table set via CMD $17,

which describe a quarter period.

(s. left)

8.2 Calculation of the microstep-frequency

i

div

i

clk

step

micro

v

clkdiv

f

f

+

−

⋅

+

=

14

2

1

• full step frequency=1/16 microstep frequency

• f

clk

is 20MHz

• clkdiv is the same for all motors (range 0..31)

• v

i

respectively vakt is the velocity of each motor (range: –511..+511)

• div

i

can be parameterized for each motor (range 0..3)

Note: The microstep frequency must not exceed 200kHz.

x

0

2

π

0

π

π

2

4

3

π

)

(

ϕ

f

ϕ

box

rh

om

b

circ

le

1

2

π

y

up to 16 micro steps

1 full step

16

m

icro

ste

ps

wi

thin a

qua

dra

nt

1 f

ull

ste

p

2

1

2

π

)

(

ϕ

f

(16 values for generating the current)

A

0

0

step

full

/

rectangle

(1)

triangle

(3)

(default)

sinus

(2)

(3)

(1)

(2)