P r o g r a m m i n g, Hints for programming, Strategy for parameter setting – RMS Technologies 4-AXIS CONTROLLER/DRIVER User Manual

Page 15: Setting of motor current, Velocity configuration (global), 1 hints for programming, 511 and small values div

S I X P A C K / Q U A D P A C K

15

7 P R O G R A M M I N G

7.1 Hints for Programming

⇒

Strategy for Parameter Setting

The Pack can be parameterized for standard applications with a few commands since it is pre-set with

default values. However these default values should not substitute a thorough configuration of all

parameters in a given application. Normally the following parameters should be configured for your

application:

⇒

Setting of Motor Current

Configure maximum current (s. CMD $10) and current control (s. CMD $11) as needed. The minimum

current (which provides proper microstepping) selected by current control is 19% (Index 6) for every

parameter.

⇒

Velocity Configuration (global)

Calculate clkdiv (s. CMD $12) with the step frequency formula (s. begin of chapter Instruction Set) so

that the required maximum step velocity is achieved with v

i

= 511 and small values div

i

= 0 or 1.

⇒

Setting of starting Velocity, max. Velocity and max. Acceleration

These values (s. CMD $13 and $14) should be adapted to the motor type, mechanical load, and so on.

As a reference value div

i

should be set so, that the maximum velocity vmax could be set between 256

and 511. This way maximum resolution is obtainable. Then the acceleration amax can be configured.

The velocity vstart should not be set too low.

⇒

Setting of Motor Parameters and Reference Search Parameters

These settings describe the axis type, the reference search, and so on. For time saving purposes both,

fast reference search FastRef (s. CMD $15 P6, Bit1) should be activated and the maximum velocity for

this reference search should be set. To avoid errors caused by vibrations of the motor during fast

reference search, de-bouncing of the reference switch FilterSwitch (s. CMD $15 P5, Bit7) should be

activated, too, and the mask for reference point de-bouncing (s. CMD $16) should be programmed with

an applicable value. vmin (always used with predivider div

i

set to 3) will be used while exactly locating

the reference switch. The fastest possible vmin will be choosen automatically when its value is set to 0.

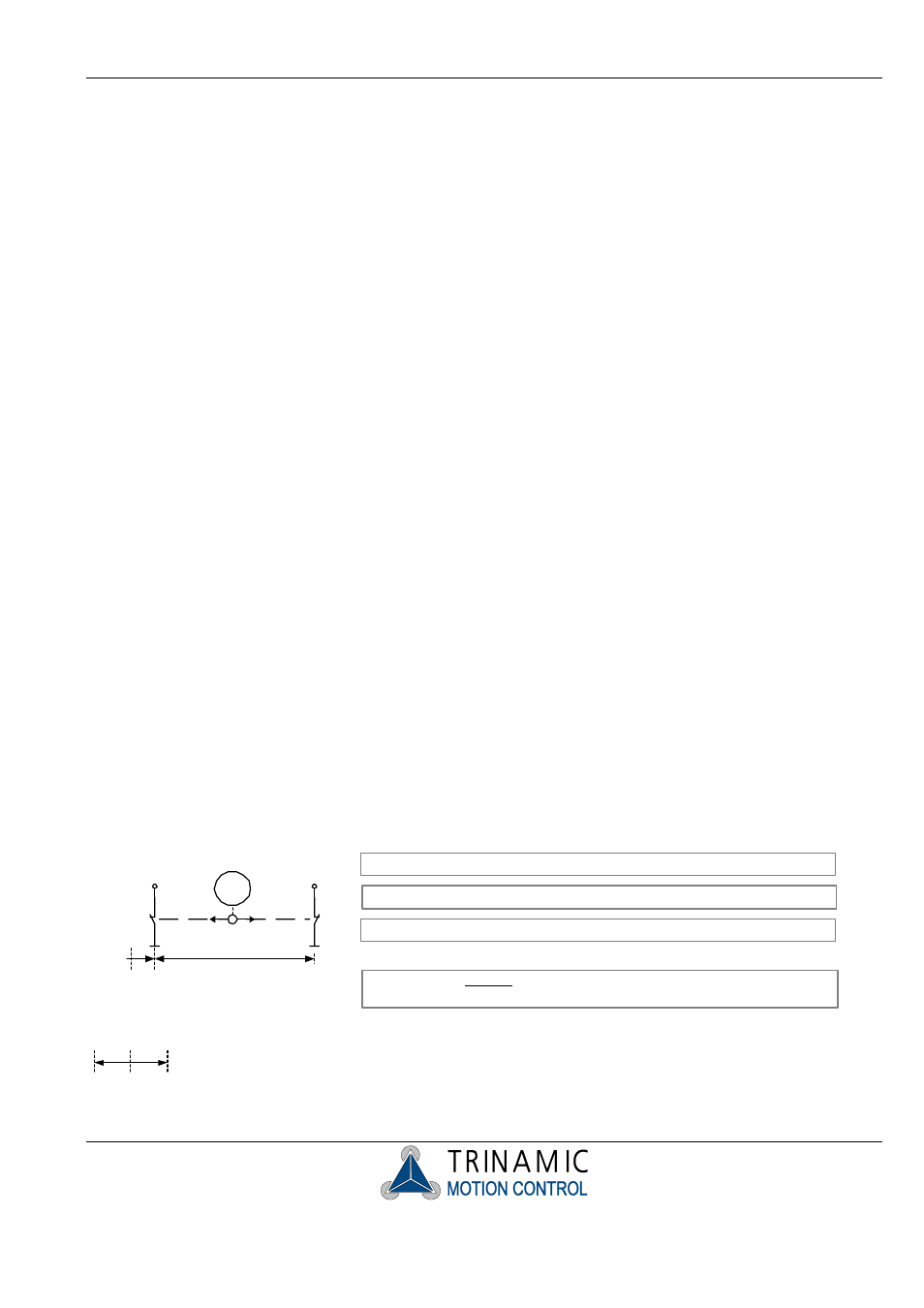

Stop

Left

Stop

Right

R

ef

er

enc

e

S

topR

poslimit

positive

direction

motor

re

fe

renc

e poi

nt

nul

l pos

iti

on

nul

l poi

nt

-o

ffs

et

traveller

te

st

nul

lr

ange

Graphic assumes null-left Flag is set and null point offset is positive(s. CM D $15).

In this configuration the reference sw itch is reliably closed at position null.

Note: testnullrange >= w idth of reference sw itch!

settings: null point-offset, poslimit -> CMD $15

testnullrange -> CMD $18