Myron L 729II User Manual

Page 54

50

figure V.A.1 for location of items described below. A DVM set to

DC Volts is required.

Note: For digital panel display perform step 8.

For analog meter display adjust DISplay calibration

control pot instead and DO NOT perform step 13

1. Ensure power is OFF.

2. Attach DVM to RECORDER output connection.

3. Turn power ON.

4. Press and hold the ZERO test switch.

5. The DVM should indicate 5.00VDC.

6. If not, adjust ZERO calibration control until DVM

indicates 5.00VDC.

7. Verify the panel meter/display, should indicate 0mV.

8. If not, adjust ORP ZERO control until display indicates

0mV.

9. Press and hold SPAN test switch.

10. The DVM should indicate 0VDC.

11. If not, adjust SPAN calibration control until DVM

indicates 0VDC.

12. Verify the panel meter/display, it should indicate

-1999mV.

13. If not, adjust DISplay control until display indicates

-1999mV.

14. Turn power OFF.

15. Re-install front panel as described in

“REASSEMBLY”, page 54.

3. CALIBRATION USING BUFFER SOLUTIONS

The BEST method of calibrating your pH or ORP Monitor/controller

is with NIST traceable Buffer Solutions (available from the Myron

L Company). Because it includes the sensor, the entire system is

calibrated.

For ORP, use 7pH buffer solution to set 0mV. Where 4 or 10 buffer

is referenced substitute ORP solution, or use the internal

-1999mV calibration.

1. Rinse a clean glass beaker thoroughly with 7pH buffer

solution.

2. Fill beaker with 7pH buffer solution.

3. Place sensor in the beaker of buffer solution. Level of

buffer solution must be at least 1” above the sensor tip.

4. Carefully shake the sensor to remove air bubbles from

around the sensor tip area.

5. Allow 5-10 minutes for temperature to equilibrate. For the

quickest and the best results, both the sensor and

solution should be at the same temperature.

6. Read the panel meter/display. The display should match

the value and units of measure shown on the bottle of

buffer solution. If the reading is different, adjust ZERO

calibration control on the main control circuit board

until reading is 7pH or 0mV.

7. Repeat steps 2 - 5. using either 4 or 10 pH buffer

solution. If reading is incorrect, adjust SPAN

calibration control on the main control circuit board

until reading matches buffer solution.

8. Turn OFF power.

9. Re-install front panel as described in

“REASSEMBLY”, page 54.

4. SENSOR SUBSTITUTE CALIBRATION

A compatible NIST traceable sensor substitute or adapter is

available from the Myron L Company. This is normally not

necessary due the “internal” electronic calibration. However, your

requirements may be such that a crosscheck or verification is

essential. The following will step you through the procedure.

NOTE: if you have previously performed a calibration with a

buffer solution this procedure will make that calibration invalid.

You must decide which is more important, a true calibration with

a buffer solution, or an electronic calibration.

1. Ensure power OFF.

2. Using a standard slot screwdriver remove the

screws on the front panel.

3. Carefully wiggle the front panel to loosen the gasket and

pull gently toward you. Do not pull more than about 8

inches/20cm or you could damage the wiring harness.

4. Turn the front panel around so that the back side is

facing you and set aside.

5. Locate and remove the sensor leads from the sensor

connector as shown in figure V.A.1.

6. Install sensor substitute as shown in figure V.C.1. with

sensor substitute label toward the transformer.

7. Turn power ON.

8. Set substitute to 7pH or 0mV.

9. If necessary, adjust ZERO calibration control until

reading is 7pH or 0mV.

10. Reset substitute to either 4pH or 10pH (-177 or +177mV).

11. If necessary, adjust SPAN calibration control until

reading is 7pH or 10pH (-177 or +177mV).

12. After adjustment, turn power OFF.

13. Re-install front panel as described in

“REASSEMBLY”, page 54.

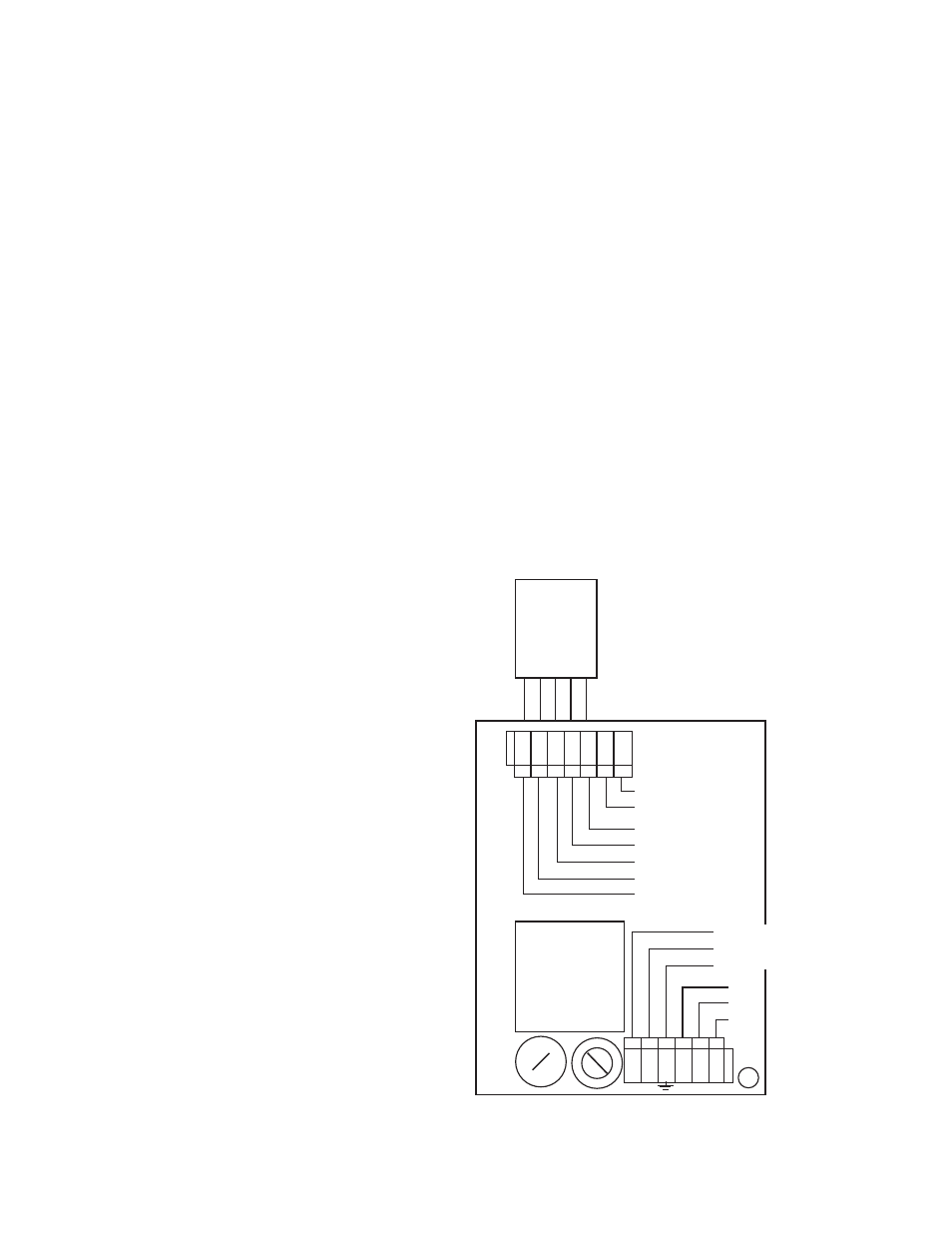

ALARM

CONTROL

RELAY

MAIN

INPUT

POWER

HOT-BLK/+DC

NEU-WHT/-DC

GND-GRN

}

}

Figure V.C.1.

ELECTRICAL CONNECT DIAGRAM

CHASSIS GROUND for

OEM INSTALLATIONS ONLY

FUSE

115/230

SWITCH

L N

NC

NO

COM

0-10VDC

OUTPUT

NEU

GRN

RED

WHT

BLK

(+)

(-)

}

}

SENSOR SUBSTITUTE

LABEL TOWARD

TRANSFORMER

TRANSFORMER

SENSOR

SE

NS

O

R

SU

BS

TI

TU

TE

LA

BE

L