Myron L 729II User Manual

Page 50

46

C.

SETUP PROCEDURES

These Setup procedures cover (1) converting the alarm circuit to

trigger on a decreasing or increasing reading, (2) checking out

your new Monitor/controller, (3) setting the alarm circuit set

point(s), and (4) adjusting the hysteresis.

The following require that the front panel be removed. While doing

so be careful not to strain the cable(s).

NOTE: A small screwdriver or tweaker will be required for several

of the following operations.

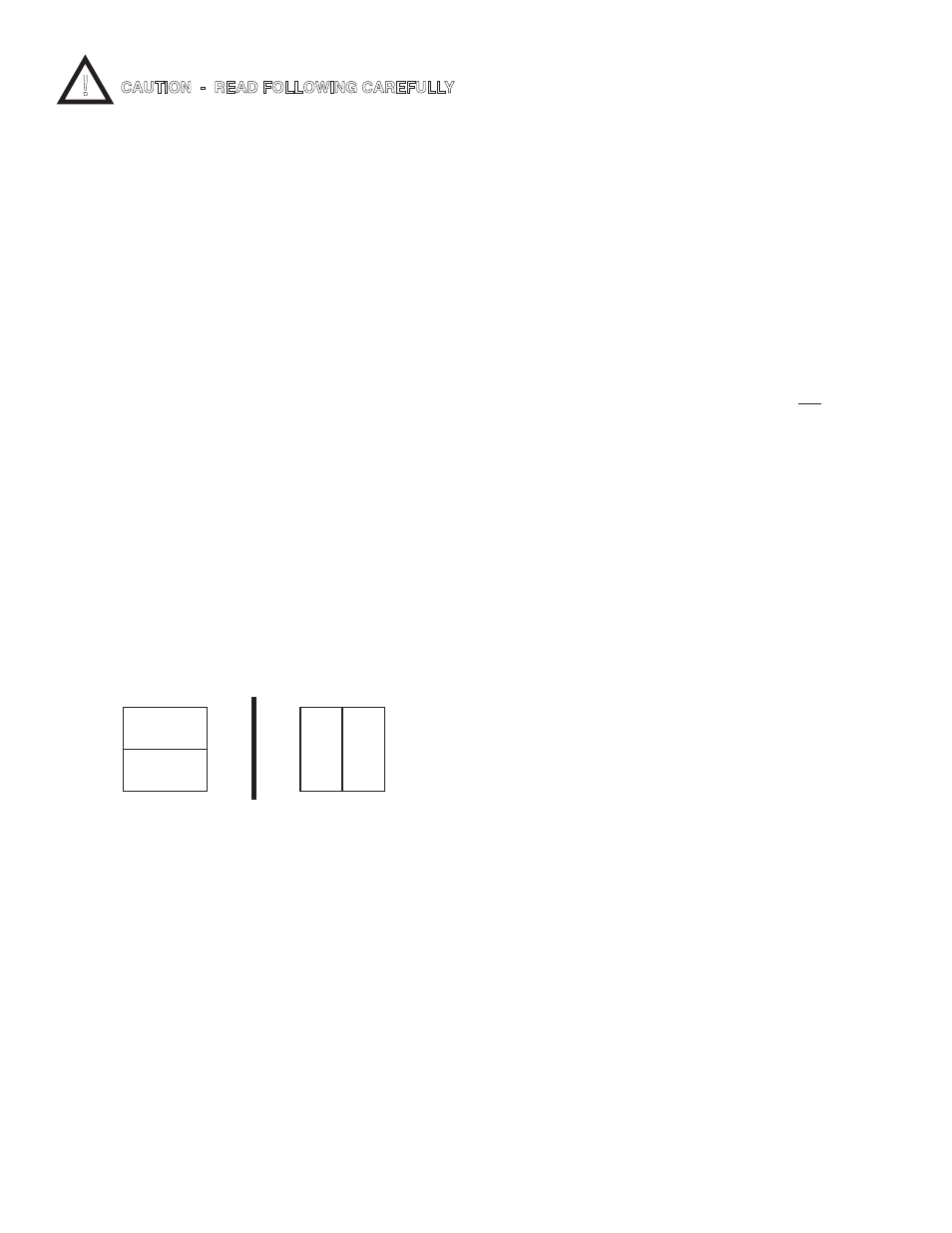

1. SET POINT CONVERSION (SPC) /

REVERSING SET POINT

The alarm/control circuit(s) on all 720 Series II pH/ORP

Monitor/controllers are configured to trigger the alarm relay as the

reading increases.

If the user’s application requires it, the alarm circuit may be easily

reconfigured to trigger the alarm relay as the reading decreases.

Refer to figure V.A.1. for the locations of the jumpers referred to

in this section.

NOTE: These instructions describe the general procedures for

converting the Monitor/controller without reference to jumper

numbers or orientation.

1. Ensure power is OFF.

2. Locate the jumper block for the alarm to be configured.

3. Make a note of the current orientation of the jumpers.

4. Remove both jumpers. This is easily done by hand. Take

care not to crush the jumpers if using pliers.

5. Rotate the jumpers 1/4 turn and reinstall them on their

posts as shown in figure IV.C.1.

2. CHECK-OUT PROCEDURES

The following check-out procedures are used to verify that the

720 Series II Monitor/controller is operating properly. It is

assumed that the Monitor/controller is powered ON, that it is

connected to an appropriate Sensor, and that the Sensor is

immersed in water within the range that the Monitor/controller will

be required to read. Refer to figure V.A.1. for the locations of the

components referred to in this section.

a. Make a note of the reading on the display.

b. Being careful not to strain the connecting cable(s),

unfasten and remove the front panel.

c. While pressing the ZERO Test Switch (ZERO), verify that

the front panel display is indicating 7pH or 0 mV reading.

If not, see Calibration, section V.C.

d. Press and hold the “SET POINT” switch on the front

panel. Using the tweaker or a small screwdriver, adjust

the Set Point trimmer adjustment screw on the circuit

board to sweep the display left and right 1pH unit or 60mV

on both sides of water reading. Listen for the alarm relay

to click ‘ON and OFF’ as the alarm set point moves past

the water reading.

e. Adjust the alarm to the desired set point value. Release

the “SET POINT” switch.

NOTE: For Models with SC/SCO module, repeat STEPS 4 & 5 to

check out Set Point #2.

3. SET POINT ADJUSTMENT

The set point setting is based upon the user’s particular water

purity specifications or requirements.

NOTE: The optional second relay/alarm is “stacked” on the first

relay/alarm, therefore, when setting the optional second

relay/alarm Set Point, the #1 Set Point must be ‘set’ first.

a. Being careful not to strain the cable, unfasten and

remove the Monitor’s front panel.

b. While depressing the “SET POINT” switch, turn

the Set Point #1 adjustment screw (See figure V.A.1)

until the desired set point value is indicated on the

display.

c. If Hysteresis adjustment is required see below. If not,

reinstall the front panel and tightly secure both retaining

screws.

4. HYSTERESIS (DEAD BAND) ADJUSTMENT

The hysteresis or dead band is approximately ±3% of the set point

at full scale as it leaves the factory. Under normal (most)

conditions it will not be necessary to adjust.

However, if you desire to make an adjustment please keep the

following in mind.

The adjustment is very simple and is based on set point location.

If the set point* is in the upper 75-100% of the scale, the

hysteresis control pot should be turned fully to the right.

If the set point is in the lower portion of the scale, i.e. 5-25 % of

scale, the control pot may be turned fully to the left.

If you are operating in the center, 25-75% of scale, the control

pot may be adjusted in the center.

Or the hysteresis or dead band may be adjusted to tighten the

control of a particular process.

CAUTION: adjusting the hysteresis too tight may cause the

alarm to fluctuate (on-off) due to flow, chemical mixing or bubbles

causing the relay to chatter. This condition is to be avoided, it

could damage your valves, pumps, etc. and will eventually

damage the relay.

* Applies to both set points if so installed.

The following is assuming the front panel is already removed and

the set points have been set, if not see above,

1. Locate the hysteresis control adjustment located next to

the Set Point #1 (SP1) adjustment - it is a single turn pot.

See figure V.A.1.

2. Adjust as described above or as desired.

3. Reassemble per below.

!

CAUTION - READ FOLLOWING CAREFULLY

JUMPER CONVERSION

Figure C.1

INCREASING

DECREASING