Myron L 729II User Manual

Page 34

19. Continue or reinstall the front panel and tightly secure

retaining screws, see REASSEMBLY, page 31.

CAUTION: The sensor input and 0-5VDC output connectors

require only a small screwdriver or a pen to push on the release

levers. The release levers may be broken or damaged if not

pushed straight toward the CB. DO NOT push the release levers

sideways.

c. System Calibration

By following these steps the complete temperature system,

module and sensor, may be calibrated to better than ±0.2°

centigrade accuracy. This procedure is similar to the electronic

calibration except the sensor is attached and is allowed to

equilibrate in “ICE” water before adjusting the ZERO calibration

control.

NOTE: One of the above electronic calibration procedures, TPC

Module or precision resistors, must be performed BEFORE the

system calibration is performed. This is required to preset the

span between zero and full scale.

1. Ice must be crushed in water to form a very thick slurry.

A slurry is that condition where the water to ice ratio is

such that only sufficient water is present to allow easy

stirring. At this point, the temperature of the water will

be 0.000°C.

2. Immerse sensor and cable approximately 2” (50mm) into

slurry.

3. Allow to equilibrate. Slurry must be constantly stirred.

4. Continue stirring until no further change in temperature is

observed on the display.

5. Adjust TP Module ZERO calibration control to 000.0.

6. Continue or reinstall the front panel and tightly secure

retaining screws, see REASSEMBLY, page 31.

4. ALARM/CONTROL FUNCTION

You have now completed the installation and set up of your

Myron L Temperature Module option. Continue to set up and

adjust the control feature of the Temperature Module option

(-TH/THO & -SC/SCO), if installed.

The following assumes the TH/THO option has been installed at

the same time as the Temperature Module.

a. Set Point Conversion (SPC) /

Reversing Set Point

As shipped from the Myron L Company your Temperature

controller is configured to ALARM/control when the temperature is

to TOO HIGH. As many uses require the temperature to be

controlled by the use of a heater or chiller, the TPO Module may

be configured to maintain an elevated or lowered temperature as

required. If the configuration is correct for your requirements skip

to Temperature Set Point Adjust.

To reverse the set point ALARM/control operation:

1. Ensure power is OFF.

2. Locate the SPC on TP/TPO circuit board. See figures

III.C.1 & III.C.11.

3. Make a note of the current orientation of the SPC

jumpers.

4. Remove both jumpers. This is easily done by hand. Take

care not to crush the jumpers if using pliers.

5. Rotate the jumpers 1/4 turn (90°) and reinstall them on

their posts as shown in figure III.C.12.

6. Continue with Set Point adjustment.

30

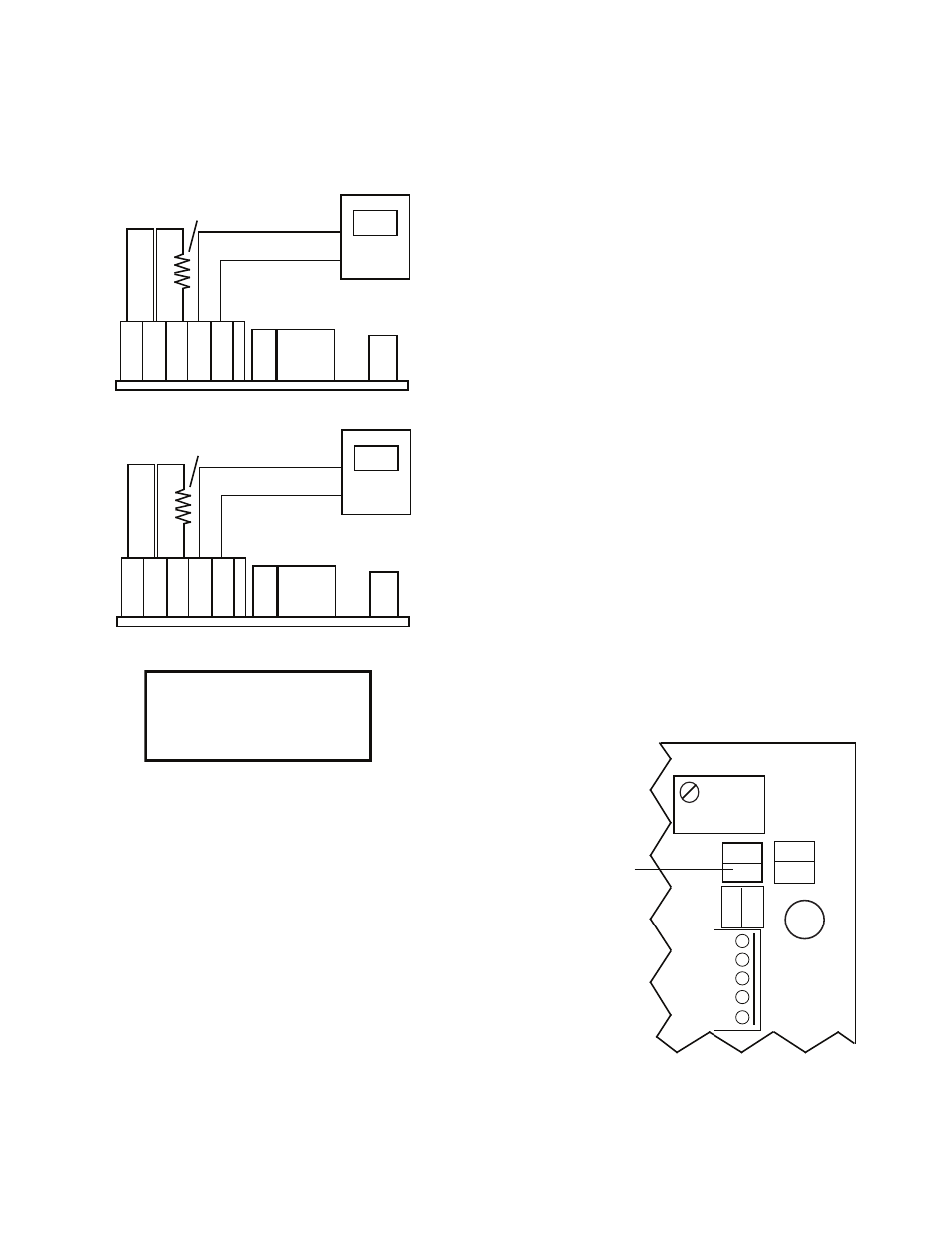

Figure III.C.8

DV

-

+

0.0

JUMPER

BR BL OR - +

Connect DVM leads as shown.

1000.0Ω RESISTOR

Figure III.C.9

DV

-

+

5.0

JUMPER

BR BL OR - +

Connect DVM leads as shown.

1758.56Ω RESISTOR

Figure III.C.10

199.9

FRONT PANEL DISPLAY

Figure III.C.11

FS

INC

INC

TEMP

CONTROL

HARNESS

DETAIL OF SET POINT CONVERSION (SPC)

ON TP/TPO MODULE AS CONFIGURED

WHEN SHIPPED FROM THE MFR.

SET POINT

CONVERSION (SPC)

DEC DEC

SPC