Power supply connections, Input connections, Remote setpoint – NOVUS Controller N1200 User Manual

Page 5: Digital input connections, Connection of alarms and outputs, Operation

Controller N1200

NOVUS AUTOMATION

5 / 13

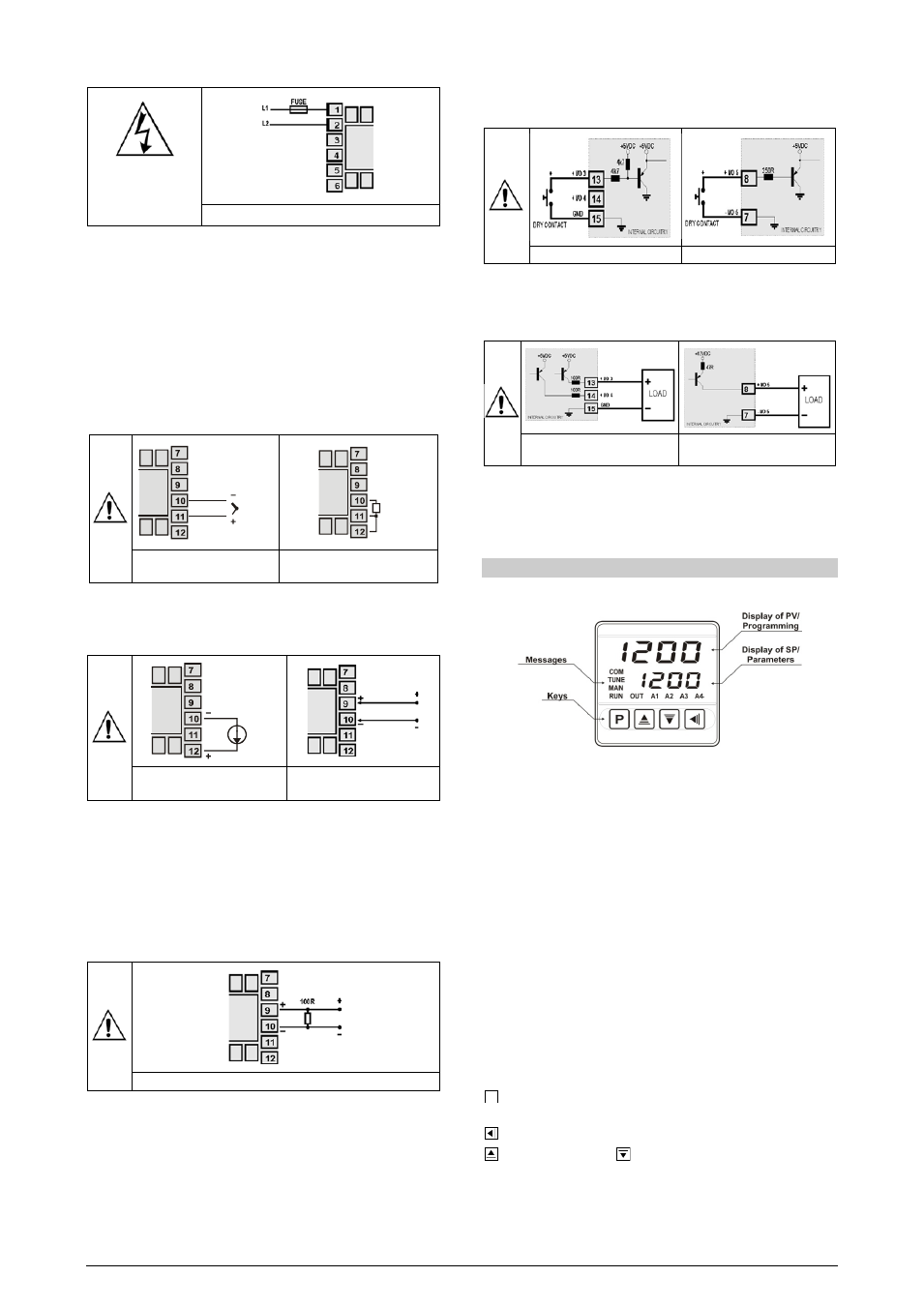

Power Supply Connections

Observe the power

requirement for the

unit. of required power

supply

Figure 2 – Power supply connections

Input Connections

• Thermocouple (T/C) and 0-50 mV

The Figure 3a indicates the wiring for the thermocouple and 0-50mV

signals. If the thermocouple wires needs to be extended, use

appropriate compensation cables.

• RTD (Pt100):

Figure 3b shows the Pt100 wiring, for 3 conductors. For proper cable

length compensation, use conductors of same gauge and length).

For 4-wires Pt100, leave one conductor disconnected at the

controller. For 2-wire Pt100, short-circuit terminals 11 and 12.

T/C, 0-50mV

Figure 3a - Connection of T/C,

0-50mV

Figure 3b - Connection of three

wire Pt100-3

• 4-20 mA:

The connections for current signals 4-20 mA must be carried-out

according to Figure 4a.

Figure 4a - Current connection

4-20 mA

Figure 4b - Connection for 5V

and 10V

• 5 V and 10 V

Refer to Figure 4b for connecting voltage signals.

Remote Setpoint

Feature available in the controller's terminals 9 and 10. When the

Remote SP input signal is 0-20 mA or 4-20 mA, an external

100Ω shunt resistor of must be connected to terminals 9 and 10 as

indicated in Figure 4c.

Figure 4c - Connection for remote SP

Digital Input Connections

Figures 5a and 5b show switches driving I/O 3 and I/O 5. The same

scheme applies to I/O 4

Figure 5a – I/ O3 a Digital Input Figure 5b – I/O5 a Digital Input

Connection of Alarms and Outputs

The I/O channels, when configured as outputs, must have their load

limit capacities observed, according to the product specifications.

Figure 6a – I/ O3 or I/O4 with

output pulse for SSR.

Figure 6b – I/O5 with output

pulse for SSR.

I/O3, I/O4 and I/O5 can also be configured as digital outputs (I/O3 and

I/O4 provide a 5 Vdc output signal whereas I/O5 a 12 Vdc signal). An

example of usage is shown in Figure 6a for the I/O3 and in Figure 6b

for the I/O5. I/O5 is electrically isolated from the sensor input

OPERATION

The controller's front panel, with its parts, can be seen in the Figure 7:

Figure 7 - Identification of the parts referring to the front panel

Display of PV/Programming: Displays the current value of PV

(Process Variable). When in configuration mode, it shows the

parameters names.

Display of SP/Parameters: Displays the value of SP (Setpoint).

When in configuration mode, it shows the parameters values.

COM indicator: Flashes to indicate communication activity in the

RS485 interface.

TUNE indicator: Stays ON while the controller is in tuning process.

MAN indicator: Signals that the controller is in the manual control

mode.

RUN indicator: Indicates that the controller is active, with the control

output and alarms enabled.

OUT indicator: For relay or pulse control output; it reflects the actual

state of the output. If an analog output is assigned for control, the

OUT indicator lights continuously.

A1, A2, A3 and A4 indicators: signalize the occurrence of alarm

situation.

P

P Key (Program key): used to walk through the menu

parameters.

Back Key: used to retrocede parameters.

Increment key and

- Decrement key: allow altering the

values of the parameters.

When the controller is powered on, its firmware version is presented

for 3 seconds, after which the controller starts normal operation. The

values of PV and SP are displayed and the outputs are enabled.

Pt100

4-20mA