Link of programs, Event alarm, Determination of pid parameters – NOVUS Controller N1200 User Manual

Page 10

Controller N1200

NOVUS AUTOMATION

10 / 13

The program tolerance defines the maximum deviation between PV

and SP for the execution of the profile. If this deviation is exceeded,

the program will be halted until the deviation falls to within the

tolerance band.

Programming 0 (zero) in the “Ptol” parameter disables the program

tolerance and the profile execution will continue regardless of the PV

value (time priority as opposed to SP priority).

LINK OF PROGRAMS

It is possible to create a more complex program, with up to 180

segments, joining the 20 programs. This way, at the end of a program

execution the controller immediately starts to run the next one, as

indicated in the “LP".

To force the controller to run a given program or many programs

continuously, it is only necessary to link a program to itself or the last

program to the first.

SV

Time

T1

T2

T3

T4

T5

T1

T2

T3

T4

SP0

SP1

SP2

SP3

SP4

SP5 / SP0

SP1 SP2

SP3

SP4

Program 1

Program 2

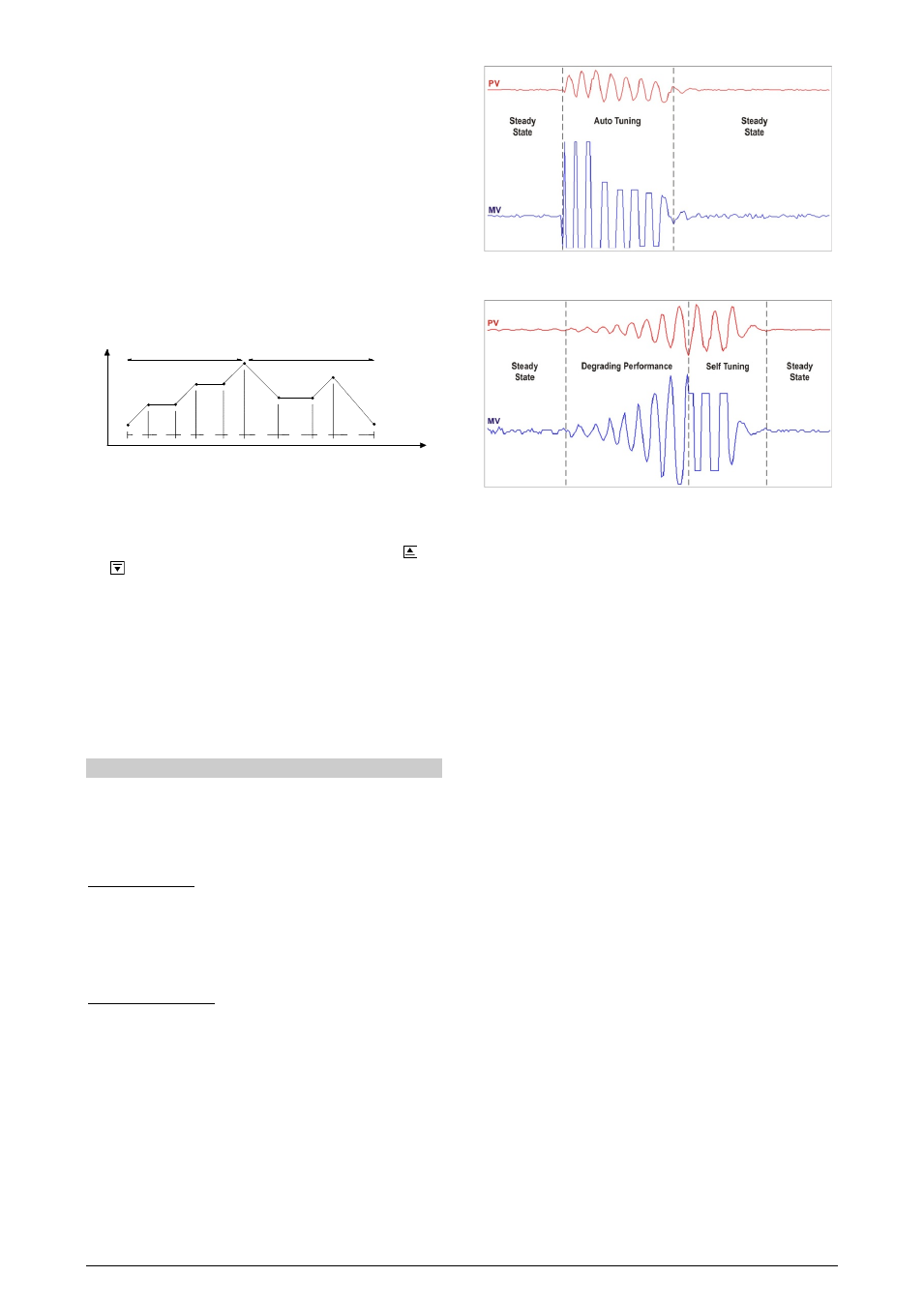

Figure 10 - Example of interlinked programs

EVENT ALARM

The Event Alarm function associates the alarms to specific segments

of a program. The information of which alarms are to be activated or

deactivated is given in parameters “ PE1“ to “ PE9. Press the

and

keys until the desired alarm numbers are displayed.

The Event Alarm requires that the Alarm function be configured as

“rS “.

Notes:

1. If PtoL is different than zero, the controller will wait for the PV to

reach the first program set point SP0 in order to start the

program execution. Otherwise, it will start promptly.

2. Should any power failure occur, the controller resumes the

program execution at the beginning of the segment that was

interrupted.

DETERMINATION OF PID PARAMETERS

The determination (or tuning) of the PID control parameters in the

controller can be carried out in an automatic way and auto-adaptative

mode. The automatic tuning is always initiated under request of the

operator, while the auto-adaptive tuning is initiated by the controller

itself whenever the control performance becomes poor.

Automatic tuning: In the beginning of the automatic tuning the

controller has the same behavior of an ON/OFF controller, applying

minimum and maximum performance to the process. Along the

tuning process the controller's performance is refined until its

conclusion, already under optimized PID control. It begins

immediately after the selection of the options FAST, FULL, RSLF or

TGHT, defined by the operator in the parameter ATUN.

Auto-adaptive tuning: Is initiated by the controller whenever the

control performance is worse than the one found after the previous

tuning. In order to activate the performance supervision and auto-

adaptative tuning, the parameter ATUN must be adjusted for SELF,

RSLF or TGHT. The controller's behavior during the auto-adaptative

tuning will depend on the worsening of the present performance. If

the maladjustment is small, the tuning is practically imperceptible for

the user. If the maladjustment is big, the auto-adaptive tuning is

similar to the method of automatic tuning, applying minimum and

maximum performance to the process in ON/OFF control.

Figure 11 – Example of auto tuning

Figure 12 - Example of auto-adaptative tuning

The operator may select, through the ATUN parameter, the desired

tuning type among the following options:

• OFF: The controller does not carry through automatic tuning or

auto-adaptative tuning. The PID parameters will not be

automatically determined nor optimized by the controller.

• FAST: The controller will accomplish the process of automatic

tuning one single time, returning to the OFF mode after

finishing. The tuning in this mode is completed in less time, but

not as precise as in the FULL mode.

• FULL: The same as the FAST mode, but the tuning is more

precise and slower, resulting in better performance of the P.I.D.

control.

• SELF: The performance of the process is monitored and the

auto-adaptative tuning is automatically initiated by the

controller whenever the performance becomes poorer.

After a tuning cycle, the controller starts collecting data from the

process for determining the performance benchmark that will

allow evaluate the need for future tunings. This phase is

proportional to the process response time and is signaled by the

flashing TUNE indication on the display. It is recommended not

to turn the controller off neither change the SP during this

learning period.

• rSLF: Accomplishes the automatic tuning and returns into the

SELF mode. Typically used to force an immediate automatic

tuning of a controller that was operating in the SELF mode,

returning to this mode at the end.

• TGHT: Similar to the SELF mode, but in addition to the auto-

adaptative tuning it also executes the automatic tuning

whenever the controller is set in RUN=YES or when the

controller is turned on.

Whenever the parameter ATUN is altered by the operator into a

value different from OFF, an automatic tuning is immediately initiated

by the controller (if the controller is not in RUN=YES, the tuning will

begin when it passes into this condition). The accomplishment of this

automatic tuning is essential for the correct operation of the auto-

adaptative tuning.