Maintenance – NOVUS N1020 User Manual

Page 7

NOVUS AUTOMATION

7/8

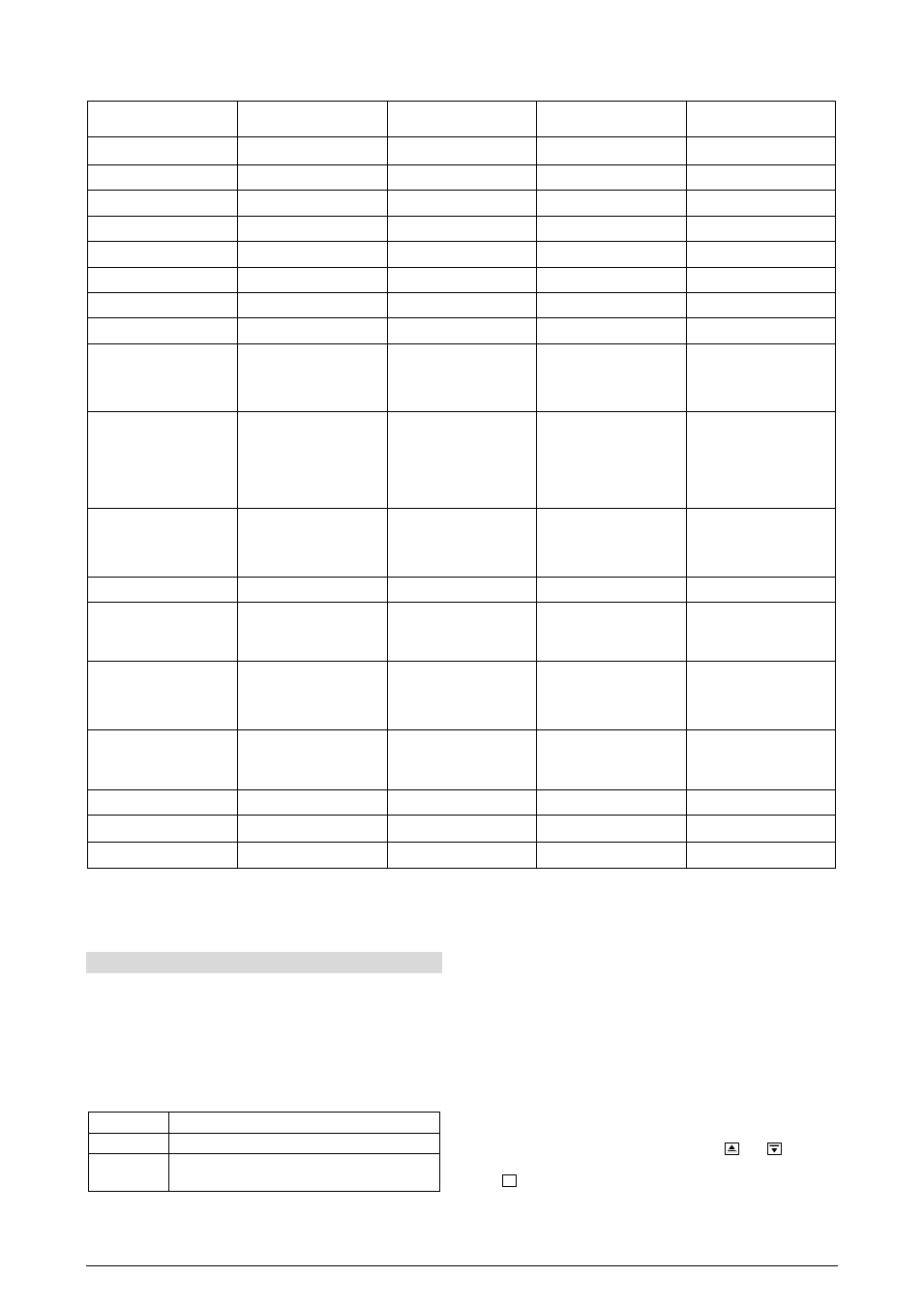

N1020 PARAMETER TABLE

OPERATING LEVEL

TUNING LEVEL

ALARM LEVEL

CONFIGURATION LEVEL

CALIBRATION LEVEL

PV

atvn

Fv.a1

Type

Pass

( * )

Timer

pb

Fv.a2

fltr

(alib

SP

ir

Sp.a1

Dp.po

In.L(

T1me

dt

Sp.a2

vnI t

In.k(

Rate

(t

Bl.a1

0ffs

rstr

RUN

kyst

Bl.a2

Sp.ll

ovll

ACt

Xy.a1

Sp.xl

ovkl

sfst

Xy.a2

T1me

(j

OUT1 (pulse)

- Control

- AL1

- AL2

A1.t1

Tm.en

(Enables the timer in the

operating level)

Pas.(

OUT2 (relay 1)

- Control

- AL1

- AL2

A2.t1

T.str

(starts Timer in operating level)

- SP

- RUN

- F key (reset)

- F key (on/off)

Pas.(

A21t2

T.e.(.0

YES Disables the outputs

(RUN=NO)

NO – Doesn’t disable outputs

Prot

A2.t2

Rate

Freq

r.ten

(shows the Rate

parameter in

the operating level)

Snk

Most significant digits of the

instrument serial number

RUN

- YES

- NO

- F key

Snl

Least significant digits of the

instrument serial number

rv.en

(shows the

Rvn

parameter in

the operating level)

bavd

prty

Addr

( * ) The PASS prompt precedes the parameters on the protected levels.

MAINTENANCE

PROBLEMS WITH THE CONTROLLER

Connection errors and inadequate programming are the most

common errors found during the controller operation. A final revision

may avoid loss of time and damages.

The controller displays some messages to help the user identify

problems.

MESSAGE

DESCRIPTION OF THE PROBLEM

----

Open input. No sensor o signal.

Err1

Err6

Connection and/or configuration errors. Check the wiring

and the configuration.

Other error messages may indicate hardware problems requiring

maintenance service.

CALIBRATION OF THE INPUT

All inputs are factory calibrated and recalibration should only be done

by qualified personnel. If you are not familiar with these procedures

do not attempt to calibrate this instrument.

The calibration steps are:

a) Configure the type of input to be calibrated.

b) Configure the lower and upper limits of indication for the

maximum span of the selected input type.

c) At the input terminals inject a signal corresponding to a known

indication value a little above the lower display limit.

d) Access the parameter inLC. With the keys

and

adjust the

display reading such as to match the applied signal. Then press the

key.

e) Inject a signal that corresponds to a value a little lower than the

upper limit of indication.

Note: When checking the controller calibration with a Pt100

simulator, pay attention to the simulator minimum excitation current

P