Start loggings, Stop loggings, Channels – NOVUS LogBox-DA User Manual

Page 3: Channel 1 – digital pulse loggings, Channel 2 – analog input, Electrical connections, Connections in the ip65 model

LogBox-DA

NOVUS AUTOMATION

3/7

START LOGGINGS

Immediately: The logger starts logging as soon as the configuration

is applied. Not valid when the option ‘Daily Repetition’ is selected.

Day / Hour: Logging starts at a defined date and time. The date

defined is used for the Daily Repetitions option as well.

STOP LOGGINGS

At Full Memory: Loggings can be stored up to the full memory

capacity is reached.

Wrap around: Logging never stops. The LogBox-DA will keep on

recording the readings and when the memory is full it will overwrite

the oldest record in a circular or wrap around manner.

After a defined number of readings: The logger will stop logging

after the number of readings here defined is reached. Not valid when

the option Daily Readings is selected.

Day / Hour: The LogBox-DA will stop logging at the user-defined

date and time. Not valid when the option ‘Daily Repetition’ is

selected.

CHANNELS

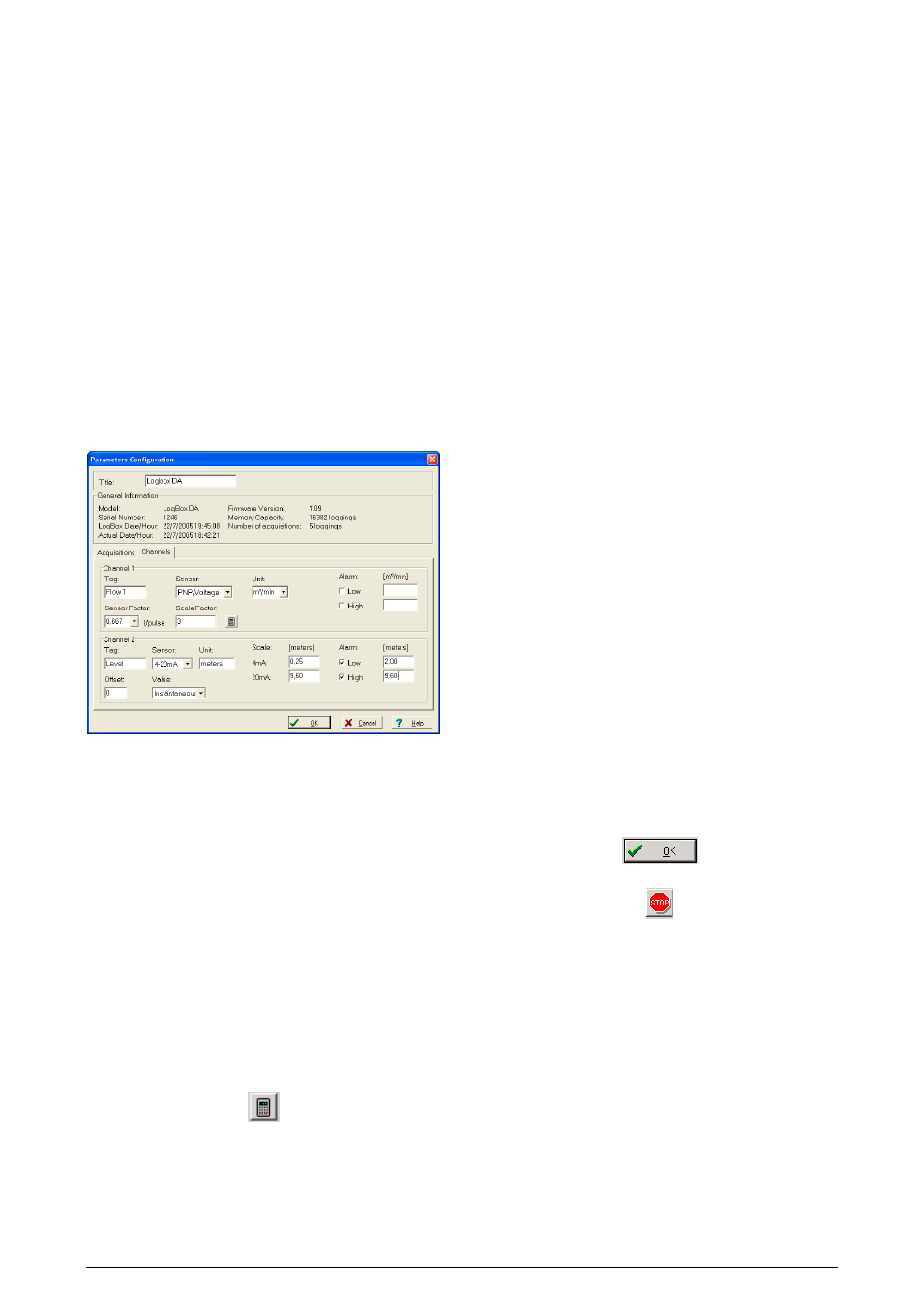

By selecting the “Channels” tab, the user is able to choose the

individual settings for each input channel, as Fig. 7 shows.

Fig. 7 – Parameters for Input Channels Configuration

CHANNEL 1 – DIGITAL PULSE LOGGINGS

Configuration options provided for Channel 1 are:

Tag: Defines a name (up to 8 characters) for identifying the variable

to be measured.

Sensor: selects the input type of the channel: Unabled,

PNP/Voltage, NPN, Dry Contact

Unit: Defines the input variable unit. Flow measurement is default,

however, other units can be defined by typing the unit in the text box.

Sensor Factor: Defines the amount of input per pulse. Liquids flow

measurement is default (liters per pulse.) It can assume any value

between 0.000001 and 16383.

Scale Factor: Adjusts the readings such as to represent a particular

flow measurement unit. This factor can be automatically calculated

(the software computes the value taking into account the interval

between loggings and the sensor factor) by using the button:

It can assume values between 0,000001 and 65535.

Alarm: The routines for alarms LOW and HIGH are executed at the

end of the logging period, informing the occurrence of an alarm by

flashing the alarm LED in the front panel.

LOW defines the minimum value under which the alarm is triggered;

HIGH defines the maximum value above which the alarm is

triggered. Once activated, the alarm LED indicator stays so even

after the alarm-triggering situation has ceased.

CHANNEL 2 – ANALOG INPUT

The options provided for Channel 2 configurations are:

Tag: Defines a name (up to 8 characters) for identifying the variable

to be measured.

Input: The signal applied to the logger second input is defined here.

The following options are offered: None (disabled), 4-20 mA, 0-20

mA, 0-50 mV, 0-10 V. The option selected must be compatible with

the LogBox internal jumper configuration. See configurations on

Table 1.

Unit: Defines the variable unit.

Scale: Defines the range, in engineering units, for representing the

input variable measured in input 2. Adjustable from –32000 to

+32000.

Offset: Allows fine offset corrections on the measured value.

Value: Defines readings recording mode:

- Instantaneous: The instant value read at the logging time;

- Average: Arithmetic average of 10 consecutive samples

equally spaced over the logging interval;

-

Minimum: Records in memory the minimum value of 10

consecutive readings in the logging interval;

- Maximum: Records in memory the minimum value of 10

consecutive readings in the logging interval;

Alarm: The routines for alarms LOW and HIGH are executed every

time the logger samples the inputs, informing the occurrence of an

alarm by flashing the alarm LED in the front panel.

LOW defines the minimum value under which the alarm is triggered;

HIGH defines the maximum value above which the alarm sensor is

triggered. Once activated, the alarm LED indicator stays so even

after the alarm-triggering situation has ceased.

After filling all the fields, send the configuration to the logger by

clicking on the button

To stop loggings, click on the button:

ELECTRICAL CONNECTIONS

Only the input channels connections and the External Battery Switch

(when used) are needed. The logger is exclusively powered by its

internal battery.

In the IP65 models, the inputs and the signal for activating the

external power supply are located inside the logger case, which must

be opened for accomplishing the connections.

In the IP67 model, proper connectors are provided for this purpose,

as shown in Fig. 9.

CONNECTIONS IN THE IP65 MODEL

Open the logger’s cover to get access to the block terminals and the

configuration jumpers. Connection cables must pass through the

compress fitting located at the bottom of the case. Figure 8 indicates

the signals polarity.