Channel 1 multiplication factor, Logchart-ii, Installing logchart-ii – NOVUS LogBox-DA User Manual

Page 2: Running logchart-ii, Optic interface ir-link3, Configuring the logger, General information, Acquisitions

LogBox-DA

NOVUS AUTOMATION

2/7

CHANNEL 1 MULTIPLICATION FACTOR

Channel 1 was designed to count electric pulses from liquid flow

meters (litters per pulse, for example). The amount of liquid

corresponding to each pulse and the unit of flow can be easily

configured.

Although suited to flow measurements, channel 1 can measure any

variable whose signal is an electric pulse (energy, production

batches, etc). The user can define a new unit by typing it in the

corresponding text box. The expression l/pulse in the multiplication

factor is meaningless in this case, so please disregard it.

LOGCHART-II

INSTALLING LOGCHART-II

To install the LogChart II, execute the LC_II_Setup.exe program

provided in the CD. The installation wizard will then guide you

throughout the installation process.

RUNNING LOGCHART-II

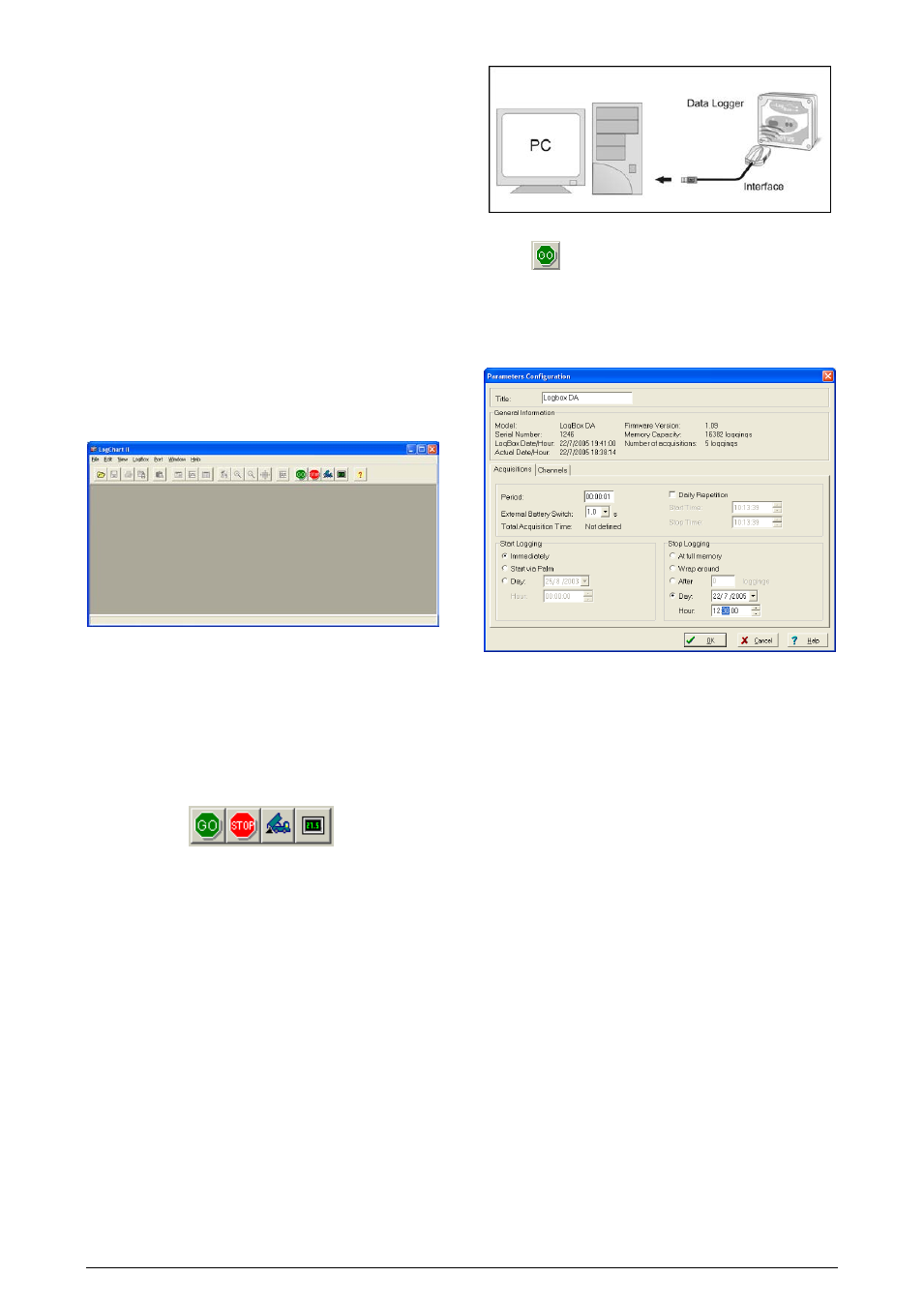

Start the program. The main window will appear on the screen, as in

Fig. 3.

Fig. 3 – LogChart-II main window

The LogChart II requires a communication port to talk to the logger.

Clicking on the menu Port, all free communication ports available in

the computer will be listed, including the USB port if the driver is

installed. Select one and connect the corresponding wand (IR-

LINK3/RS232 or IR-LINK3/USB) to it. The chosen port will be

remembered next times the LogChart II is initiated.

When the selected port is successfully opened, the LogChart II initial

screen is opened, enabling the buttons below:

Fig. 4 – Buttons enabled when the communication port of choice is valid

OPTIC INTERFACE IR-LINK3

Configuring, monitoring or downloading data from the logger through

LogChart-II requires that the IR-LINK3 communication interface be

connected to your PC. This interface is sold separately.

The IR-LINK3 interface sends and receives data to/from the logger

through infrared signals.

The Windows wizard for new USB devices pops-up automatically.

Select then the IRLink driver provided in d:\IRLink_Driver. (d: is the

driver used in the installation). After installation is completed, the IR-

LINK3 interface is recognized whenever it is connected to the PC.

NOTE: After the USB driver installation, the LogChart II must be

opened again. In the “Port” menu, choose the same port selected for

the optical interface communication (COM1, COM2,…or USB).

CONFIGURING THE LOGGER

Make sure the IR-LINK3 wand is connected to the PC port selected.

The interface must be pointed towards the logger communication

window (see Fig. 5) at a distance of about 15 cm.

Fig. 5 – Infrared interface position

Click the

button to start the communication between the logger

and the software; the Parameters Configuration window is then

displayed (Fig. 6), showing the current configuration and information

about the logger. New configuration parameters defining the

operation mode for a new application can be entered. The fields of

the configuration window are described bellow.

Fig. 6 – Configuration window

GENERAL INFORMATION

General information on the top of the screen informs the model, serial

number, logger current date/time, PC date/time, firmware version

(logger model version), memory capacity and used memory.

The time is constantly updated in this screen, provided that the

logger and the PC are communicating.

ACQUISITIONS

Interval: It determines the interval between readings in the hh:mm:ss

format. New data is stored in the logger memory after each time

interval.

External Battery Switch time: Defines an interval of time preceding

each measurement for turning on the power supply of external

devices (4-20 mA transmitters, for example). This feature is intended

for saving power when the external power supply is battery powered

and the logging interval is long. This signal is disabled when a

measurement is completed.

This time is limited to 10 seconds and must be less than half of the

interval between readings.

When channel 2 (analog input) is configured to Instantaneous

readings, the measurements are taken at the end of the defined

interval between readings. For Average, Minimum and Maximum

readings, the logger executes 10 readings within this interval. This

must be taken into account when defining the time to active the

external power supply (1/2 of interval/10).

Estimated Time: It informs the estimated time for the

accomplishment of programmed readings based on the logging

“Interval” and on the number of programmed readings.

Daily Repetition: Allows loggings to be repeated everyday, for

example, recording data from 8 AM to 5 PM day after day.

The start and stop times are defined in the fields “Start time” and

“Stop time.”