Recommendations for the installation, Over-temperature protection, Operation – NOVUS N1540 Process Indicator User Manual

Page 3: Description of the parameters

N1540 Indicator

NOVUS AUTOMATION

3/5

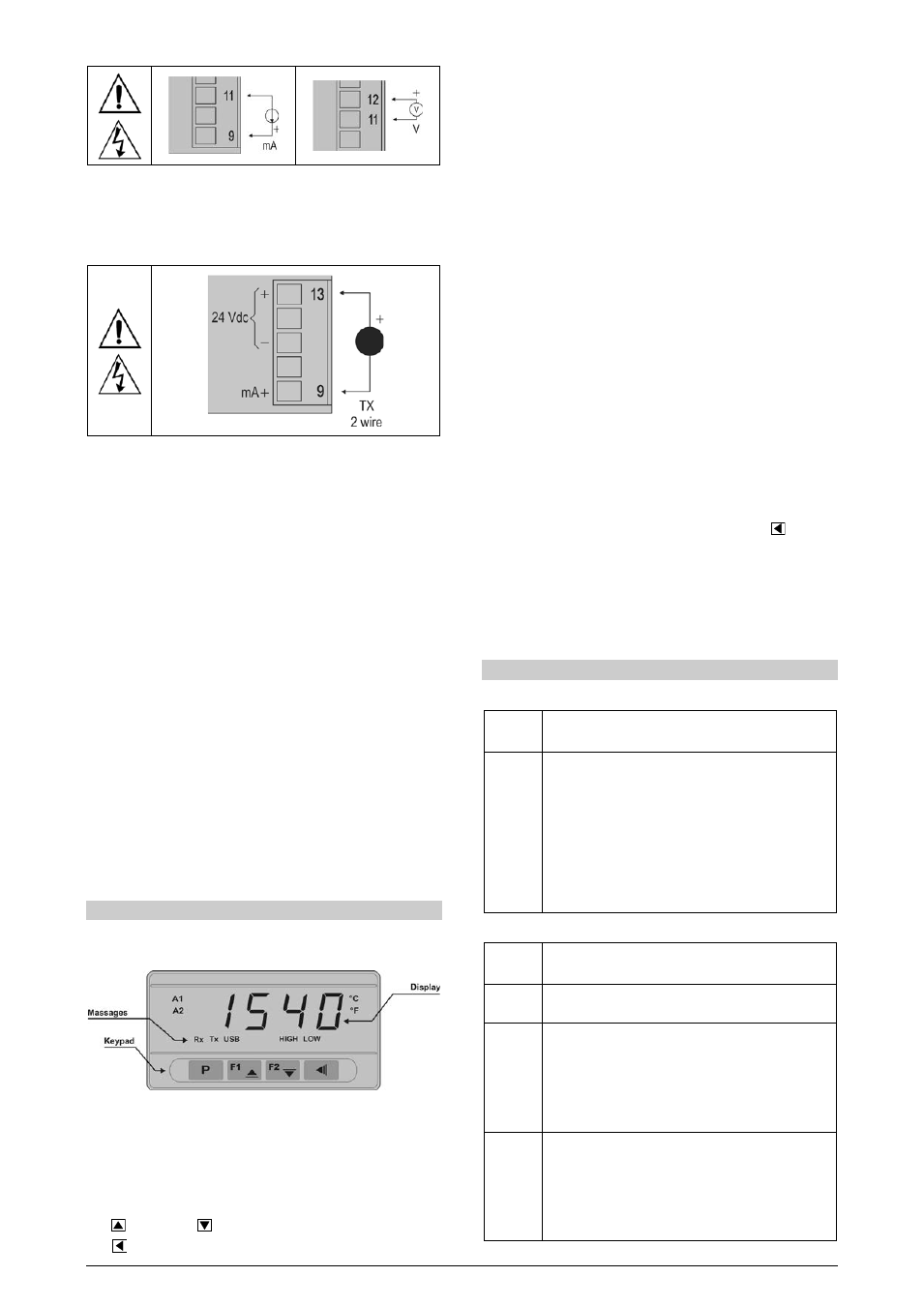

Figure 03 – Current (mA) and Voltage (V) signal connection

This indicator offers an auxiliary 24 Vdc power supply which is

tipically applied to power up two wire 4-20 mA field transmitters. The

Figure 04 presents the wiring for this application.

Figure 04 – Auxiliary 24 Vdc usage example

RECOMMENDATIONS FOR THE INSTALLATION

• To minimize the pick-up of electrical noise, the low voltage DC

connections and the sensor input wiring should be routed away

from high-current power conductors. If this is impractical, use

shielded cables. In general, keep cable lengths to a minimum.

• The input signals conductors shall be positioned throughout the

factory separate from the output and the power supply

conductors, in grounded conduits if possible.

• The power supply of the electronic instruments shall come from a

proper source for the instrumentation network.

• It is recommended to use RC FILTERS (0,1 uF in series with 100

ohms) to suppress the noise generated by contactors coils,

solenoids, etc.

OVER-TEMPERATURE PROTECTION

When designing any control system it is essential to consider what

will happen if any part of the system should fail. In temperature

control applications the primary danger is one in which the heating

remains constantly on. In any application where physical injury or

destruction of equipment might occur, it is recommend to install an

independent protection equipment, with a separate temperature

sensor, to disable the heating circuit in case of overheating. Please

note that the alarm relays within the indicator will not give protection

under all failure conditions.

OPERATION

The indicator front panel, together with its elements, can be seen on

Figure 02:

Figure 02 - Identification of the front panel parts

Display: Shows the process variable PV, the configuration

parameters prompts and their respective values/conditions.

Indicators A1 and A2: signalize the occurrence of an alarm

condition.

Key P: used to walk through the parameters in the menu cycles.

F1 /

key and F2 /

key: Used to change parameter values.

Key

: go back to the previous displayed parameter.

START UP

When the indicator is powered up, its firmware version is displayed

for 3 seconds, after which the N1540 starts normal operation, when

the value of PV is displayed and the outputs are enabled.

Before the indicator is ready to be used in a given process, it requires

some basic configuration, consisting of assigning values to the

parameters according to the desired behavior. The user shall

understand the importance of each parameter and determine a valid

condition or a valid value for each one of them.

The configuration parameters are grouped in levels according to their

affinity. The 4 parameters levels are:

1 – Operation

2 – Alarms

3 – Input

4 – Calibration

The “P” key provides the access to the levels and to the parameters

of these levels.

Keeping the P key pressed, at every 2 seconds, the indicator jumps

from one level to another, presenting the first parameter of each

level:

PV >> fva1 >> type >> pass >> PV …

To enter into a particular level, simply release the P key when the

first parameter in that level is displayed.

To walk through the parameters in a level, press the P key with short

strokes. To go back to the previous parameters, use the

Key.

The display alternates the presentation of the parameter prompt and

its value. The parameter value is displayed with a light blinking to

differentiate it from the parameter prompt.

Depending on the level of parameter protection adopted, the

parameter PASS precedes the first parameter in the level where the

protection is active. See section PROTECTION CONFIGURATION.

DESCRIPTION OF THE PARAMETERS

OPERATION CYCLE

PV

Indication Display of PV. The value of the measured

variable (PV) is shown on the upper display (red).

Sp.a1

Sp.a2

Alarm SP: Value that defines the alarm activation point.

For the alarms set up with the functions of the type

Differential, these parameters define the maximum

differences accepted between PV and a reference

value defined in the parameter ALrF.

For the alarm function ierr, this parameter is not

used.

Parameters shown in this level only when enabled in

the parameters sp1.E and sp2.E.

ALARMS CYCLE

Fva1

Fva2

Alarm Functions. It defines the functions of the alarms

among the options in Table 02.

al.rf

Reference value used by the alarms with differential

function, minimum differential or maximum differential.

Sp.a1

Sp.a2

Alarm SP: Value that defines the point of activation of

the alarm outputs. For the alarms programmed with the

functions of the type Differential, these parameters

represent the deviations.

For the ierr alarm function, this parameter has no

meaning.

Sp1.e

sp2.e

SP Enable

It allows the parameters SPA1 and SPA2 to be displays

also in the indicator operation cycle.

YES

shows the parameters SPA1/SPA2 in the

operation cycle

NO

Does not show the parameters SPA1/SPA2 in

the operation cycle