Swiftech H20 120 PREMIUM2 User Manual

Page 25

Copyright Swiftech 2007 – All rights reserved – Last revision date: 1-15-07 - Information subject to change without notice – URL:

http://www.swiftech.com

Rouchon Industries, Inc., dba Swiftech – 3400 Industry ave., suite 104, Lakewood, CA 90712 – Tel. 562-595-8009 – Fax 562-595-8769 - E Mail: [email protected]

PAGE 25 of 28

6 P

REPARING THE TUBING

Now that your radiator, water-block, pump and reservoir

are ready, it is time to cut segments of tubing and connect

the elements of the cooling system together.

In addition to the supplied high quality vinyl tubing, your kit

also comes with a 40” length of Smartcoils which, when

extended provides a sufficient length to wrap 6 feet of

tubing. Use of these coils is mandatory in order to prevent

kinking and flattening of the tube over time.

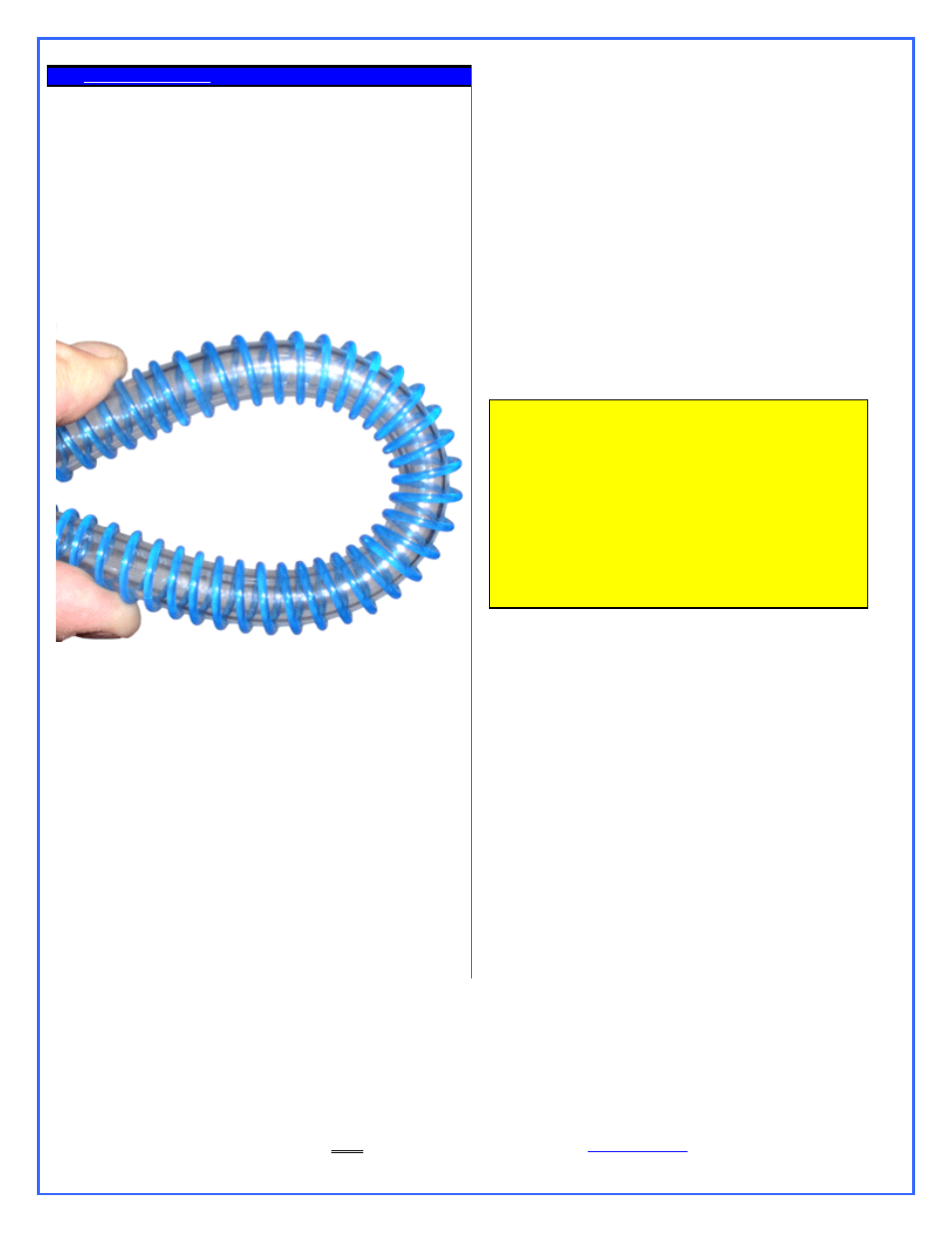

Example of wrapping for a tight bend. (shown with the blue

version for picture clarity – The kit actually comes with

clear coils).

Tight radii sections require that coils be close to each other

(1/8” spacing coil to coil). In straight sections, coils can be

spaced up to ¼” or more, coil-to-coil.

Gather the Smartcoils towards the center of the tubing, and

then pull on the ends of the tubing. This will allow the coils

to expand to their natural pitch.

Another technique to evenly spread the coils along the

tubing consists in pushing one of the extremities of the coil

clockwise. This will loosen the coils from around the tube,

and allow you to spread them easily.

Then, with one end of a tube connected to a startup

component such as the water-block for example, roughly

estimate the length that you will need to the next

component, and cut the tube and coil squarely with a pair

of scissors. Work your way through the entire circuit in the

same fashion, until you are satisfied with the tube routing.

Once everything is connected, you should then

adjust the Smartcoils coil spacing: adjust to a

wide space between each coil (up to ¼” or more

if needed) when the tube is straight, and very

close to each other in tight bends (approximately

1/8

th

of an inch or less).

With everything in place, carefully double-check

each connection. If it all looks tight and secure

proceed to the next step.

TIP! Verify that each cooler will ‘hang’ naturally

in very close to its mounted position. If the

stiffness of the tubing, or the tight radius of the

necessary bend, will not permit such, then it may

be necessary to externally support the tubing:

typically some strategically placed cable ties will

facilitate this restraint. This precaution is

particularly important with AMD® K7 class

processors, but less so with Intel® Pentium® 4,

Xeon, or AMD® K8 class processors.