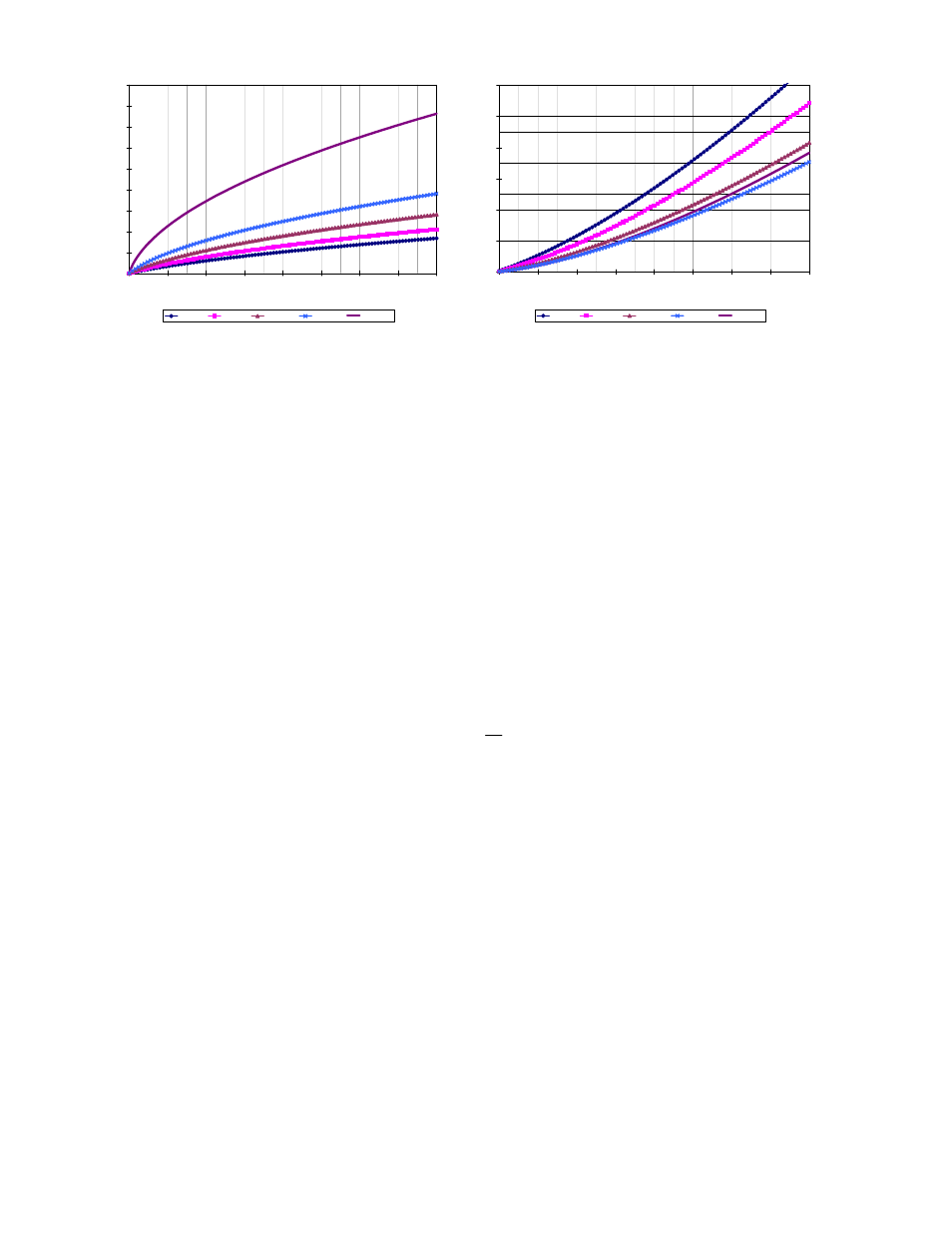

Figure 5-10, Dq r, Xq 5 . 0 2 4 – Campbell Scientific TGA100 Trace Gas Analyzer Manual User Manual

Page 78

100

200

300

400

500

600

700

800

900

1000

0

50

100

150

200

250

300

350

400

Tube Length (m)

Pressure (mB)

5 slpm

7 slpm

11 slpm

16 slpm

26 slpm

0

10

20

30

40

50

60

0

50

100

150

200

250

300

350

400

Tube Length (m)

Time (s)

5 slpm

7 slpm

11 slpm

16 slpm

26 slpm

Figure 5-10. Pressure Drop and Travel Time for 0.375" (9.5 mm) ID Tubing

Two examples are given as a guide in selecting tubing for gradient applications. The first example is a single site

gradient measurement, with the intakes located 200 m (656 ft) from the analyzer. The sample pump is the RB0021,

running at 50 Hz. Assuming the analyzer pressure is 75 mbar and allowing for 5 mbar pressure drop from the analyzer

to the pump, the maximum total flow is 22 slpm (see section 9.3). If the gradient sample flow is limited to 15 slpm to

minimize the possibility of a bias between intakes, the remaining available flow (7 slpm) is more than adequate to purge

the dryer (see section 9.4). The maximum pressure at the inlet end of the tubing depends on the altitude and the pressure

drop in the dryer. For this example the altitude is assumed to be near sea level, giving an ambient pressure of 1000

mbar. The pressure drop in the dryer is 5 mbar per slpm (see section 9.4), giving a maximum pressure at the outlet of

the dryer (inlet end of the sample tubing) of 890 mbar.

shows that for 200 m of 0.170" ID tubing, the maximum flow rate is 5 slpm, with a travel time of 20 s.

shows that 200 m of 0.250" ID tubing would allow approximately 15 slpm (interpolating between the curves

for 11 and 16 slpm), with a travel time of 16 s.

shows that 0.375" ID tubing would allow flow rates even

higher than 15 slpm, and the minimum travel time is 13 s for a flow rate of 16 slpm. All three of these tubing sizes

show that the travel time decreases for increasing flow rates until a minimum is reached, and then still higher flow rates

actually increase the travel time slightly. The minimum travel time corresponds to the minimum friction coefficient at

the threshold between laminar and turbulent flow in the tubing. This minimum occurs at a Reynolds number of

approximately 2300, where the Reynolds number is:

D

Q

R

e

36

.

55

=

Where Q is standard flow rate (slpm) and D is tubing ID (inches), at a temperature of 20° C. This friction coefficient

minimum occurs at flow rates of 5.2, 7.1, 10.4, and 15.6 slpm, for tubing IDs of 0.125, 0.170, 0.250, and 0.375 inches.

Either of the two larger tubing sizes should give acceptable results, but the 0.375" tubing is preferred for its slightly

shorter travel time. The 0.250" tubing is also a good choice, but it may not allow the full 15 slpm flow rate.

The second example is a four-site gradient, with the intakes located 85 m from the analyzer. The sample pump is the

RB0021, running at 60 Hz. Assuming the analyzer pressure is 75 mbar and allowing for 5 mbar pressure drop from the

analyzer to the pump, the maximum total flow is 26 slpm (see section 9.3). This flow must be split between the four sets

of gradient intakes and the dryers. Two dryers are used, mounted between the site selection system and the analyzer.

The sample flow is calculated from:

x

x

x

Q

5

.

0

2

4

+

+

=

where Q is the total flow to the sample pump, x is the sample flow. The first term on the right hand side represents the

flow from the four gradient intakes, the second term represents the purge flow for the sample dryer, and the third term

represents the purge flow for the purge dryer (see section 9.4.3.5). Solving this equation for x gives a sample flow of 4

slpm for a total flow of 26 slpm. For this example the altitude is also assumed to be near sea level, giving an ambient

pressure of 1000 mbar. There is no dryer mounted at the intakes, so the maximum pressure at the inlet of the sample

tube is close to 1000 mbar.

Figure 5-7 shows that approximately 4 slpm is the maximum flow rate allowed through 85 m of 0.125" ID tubing, with

a travel time of approximately 6.5 s. If 0.170" ID tubing is used (

), 4 slpm will give 500 mbar pressure at the

78