AMETEK 952 BlueOx LDT User Manual

Page 6

6

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

2. Position the non-ferrous spacer against the

piston face, followed by the magnet, and finally

the chamfered rod bushing. (If the length of

the LDT’s rod is 60.0” or longer in length, it is

recommended that a chamfered rod bushing be

used.)

3. Insert non-ferrous screws through the

chamfered rod bushing (if used), magnet,

and non-ferrous spacer, and secure items by

tightening screws.

If the leading edge of the magnet will come

closer than 2.0” from the base of the LDT’s hex

head when the piston rod is fully retracted, it

will be necessary to counterbore the magnet

assembly into the piston rod. Both the standard

1.29” four-hole magnet assembly (part number

SD0400800) and the 1.0” magnet assembly

(part number SD0410300) are designed for

counterbored mounting applications. If it has

a 1.0” magnet assembly, a snap ring will be

needed to hold it in place.

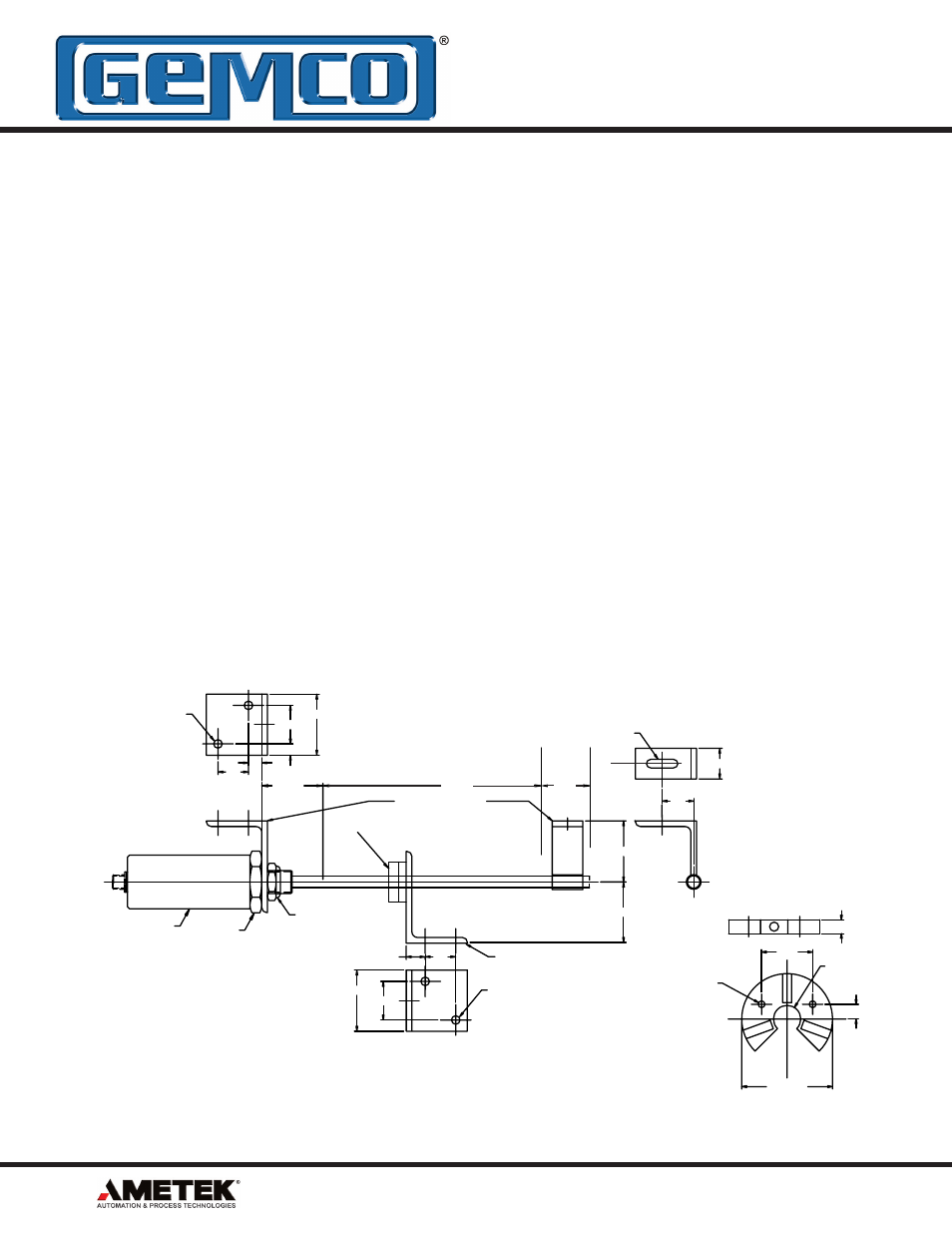

Figure 2-1: Mounting the LDT

4. Insert the LDT’s rod into the hole of the hydraulic

cylinder’s mounting bracket.

The protective Plug may need to be removed

from the hydraulic cylinder before inserting the

LDT. The end cap should contain a 3/4 - 16 UNF

- 2B threaded hole. Screw the LDT into this hole

using the threads protruding from the LDT’s hex

mounting base.

WARNING: Do not use the blue aluminum cover

of the head assembly or connector/cable nut

(either a 1 1/16" Amphenol connector or 1 3/16"

cable nut) to tighten the LDT within the bracket

(see Figure 2-1). This may damage the LDT

and will void your warranty. To tighten the LDT

within the bracket, use the 1.75" hex mounting

base on the head assembly.

At this point, the LDT should now be properly

installed inside the hydraulic cylinder. It may now

be necessary to assemble parts of the hydraulic

cylinder. For assistance in this task, refer to the

information provided by the cylinder manufacturer.

BAND

OPTIONAL

MAGNET

NULL

STROKE

DEAD

1.75 HEX

MAGNET MOUNTING

KIT (P/N 949005)

PROBE MOUNTING KIT

(P/N 949003)

2.00

2.00

3/4-16 JAM NUT

SUPPLIED W/PROBE

1.00

1.03

.28 X 1.03 SLOT

1.00

.44

1.25

2.00

.28

2 PLACES

2.00

1.25

1.00

2 PLACES

.28

.62

PROBE

3/16" X 2" X3" STAINLESS STEEL.

2. MOUNTING BRACKETS ARE MADE FROM

MOUNTING BOLTS.

1. MOUNTING KITS FURNISHED WITH

NOTES: UNLESS OTHERWISE SPECIFIED

CL

.37

2.50 REF.

.406

1.407

.75 THRU

.38

.187 THRU

(2 PLACES)

S

N

N

N

S

S

S

MAT’L.: STAINLESS STEEL.

NOTE: USE THIS MAGNET WITH ROD

SUPPORT BRACKET SD0411100