Appendix “c” - troubleshooting (cont’d) – Red Lion PCU User Manual

Page 82

APPENDIX “C” - TROUBLESHOOTING (Cont’d)

-74-

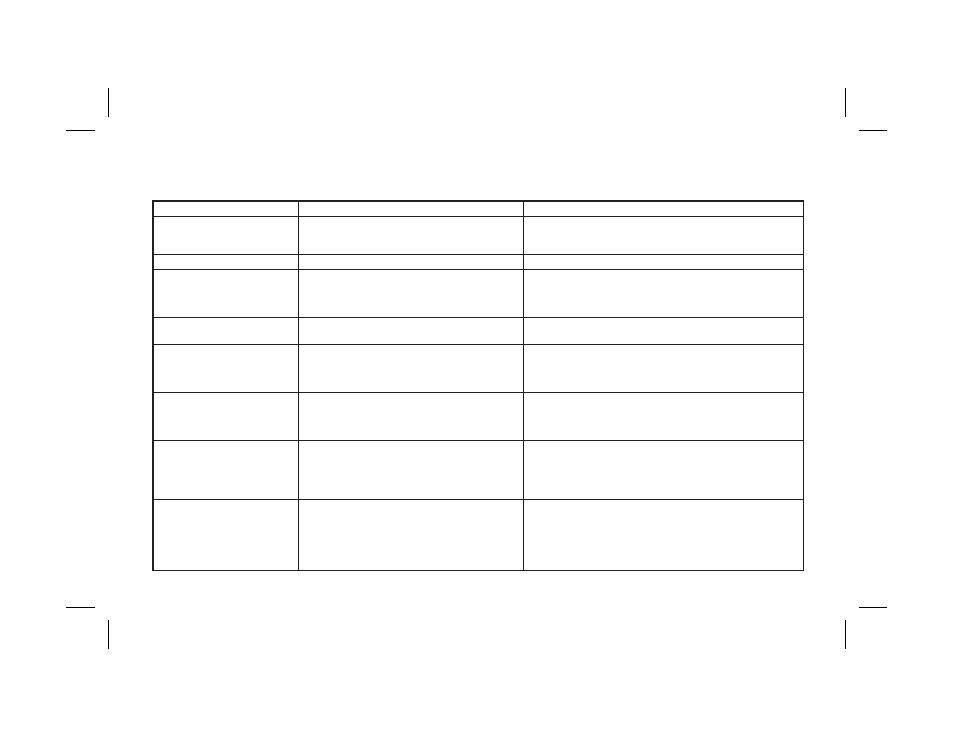

PROBLEMS

POSSIBLE CAUSE

REMEDIES

“VALV” IN DISPLAY

Valve Fail Alarm

1. Valve or valve motor jammed.

2. Loss of power to valve motor.

3. Slidewire feedback signal lost.

1. Check valve or valve motor for operation.

2. Check power to valve motor.

3. Increase valve fail time.

“SLId” IN DISPLAY

1. Slidewire feedback signal lost.

1. Check slidewire feedback signal.

DISPLAY INCORRECT OR

DISPLAY WANDERS

1. Loose or corroded connections.

2. Signal source in noisy environment.

3. Controller needs calibration.

1. Check connections.

2. Evaluate signal source location.

a. Increase digital input filtering.

3. Check calibration.

PROCESS SLUGGISH OR

NOT STABLE

1. Incorrect PID values.

1. See PID Control.

EXCESSIVE VALVE

ACTIVITY OR HUNTING

1. Insufficient valve control deadband.

2. Insufficient output dampening.

3. Incorrect PID values.

4. Valve update time too short.

1. Increase valve deadband.

2. Increase output dampening.

3. See PID Control.

4. Increase valve update time.

OUTPUTS NOT WORKING

1. Output module not installed.

2. Improperly wired.

3. Incorrect output module.

4. Defective output module.

1. Install output module.

2. Check wiring.

3. Check output module.

4. Check or replace output module.

LINEAR DC OUTPUT

NOT WORKING

1. Improper load resistance.

2. Incorrect programming or scaling.

3. Connections reversed.

4. DC voltage source in loop (4 to 20 mA only).

1. Check load resistance.

2. Check programming.

3. Check connections.

4. This is an active loop. Remove all DC voltage sources

(4 to 20 mA only).

CONTROLLER LOCKS UP

OR RESETS

1. Noise spikes entering controller due to load

switching transients.

2. Defective controller.

1. Use RC snubber across the load.

a. Use Triac output modules whenever possible.

b.Use separate AC feed line to controller.

c. Locate controller & signal lines away from noise

producing mechanisms (solenoids, transformers,etc).

2. Replace Unit.