Lgb application – Red Lion LEGEND User Manual

Page 5

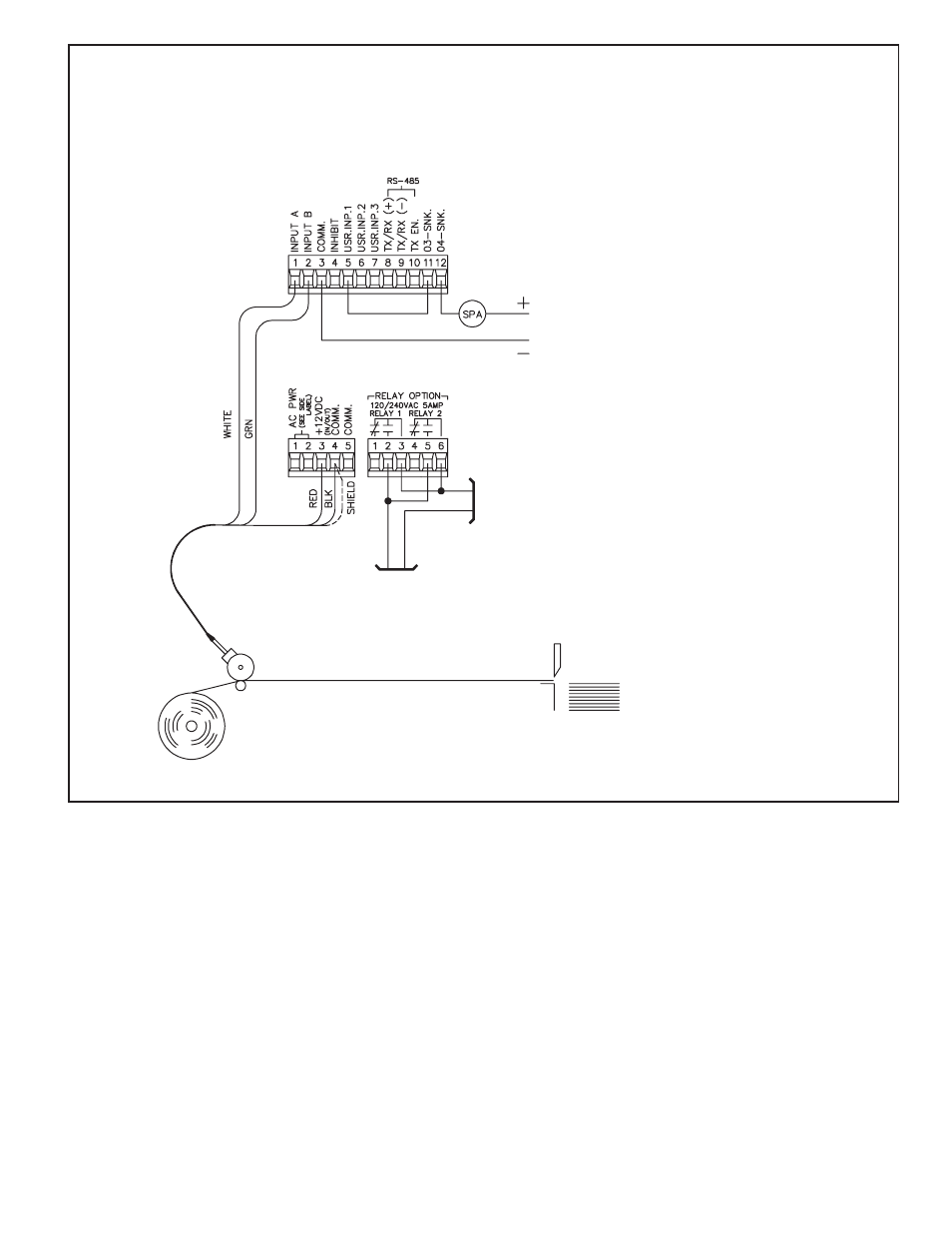

LGB APPLICATION

An order requires that sheets of material be cut in two different lengths. The operator would like to change the settings for the second length

to be cut with no down time. A Legend series LGB (Four Preset Batch Counter/Rate Indicator) is used to satisfy the requirement.

A Lenght Sensor (LSQ) with a 100 pulse per revolution (PPR) quadrature output is coupled with an LSAHC hinge clamp assemby and a

one foot circumference wheel. The LEGEND series LGB is set to the Quadrature X1 mode. With a one foot wheel, the information becomes

100pulses/foot and allows the material to be cut to the nearest 1/100 of a foot. The counter display is programmed for two decimal places to

provide a readout in 1/100 of a foot increments.

Preset value P

1

(Process count) is

programmed for the first length to

be cut for the order and Preset value

P

2

(Process count) for the second

length.

The outputs are used to control

power to the cutting knife and the

counter is programmed to reset

when Preset 1 or Preset 2 is reached.

Preset value P

3

(Batch count) is

programmed to activate User Input 1

(skip P

1

) when the total number of

pieces is reached for the first order.

Preset value P

4

(Batch count) is

programmed to stop the process

after the second order is complete.

The totalizer will keep track of the

total amount of feet used.

5

MODEL

LGB

TO AC

POWER

SOURCE

TO CUTTING

KNIFE

ACTUATOR

CUTTING

KNIFE

TO DC

POWER

SOURCE

STOP

PROCESS

ACTUATOR

SHEET STACK