0 technical data, Technical features – Sterlco SF1000 Gravimetric Additive Feeder User Manual

Page 29

29

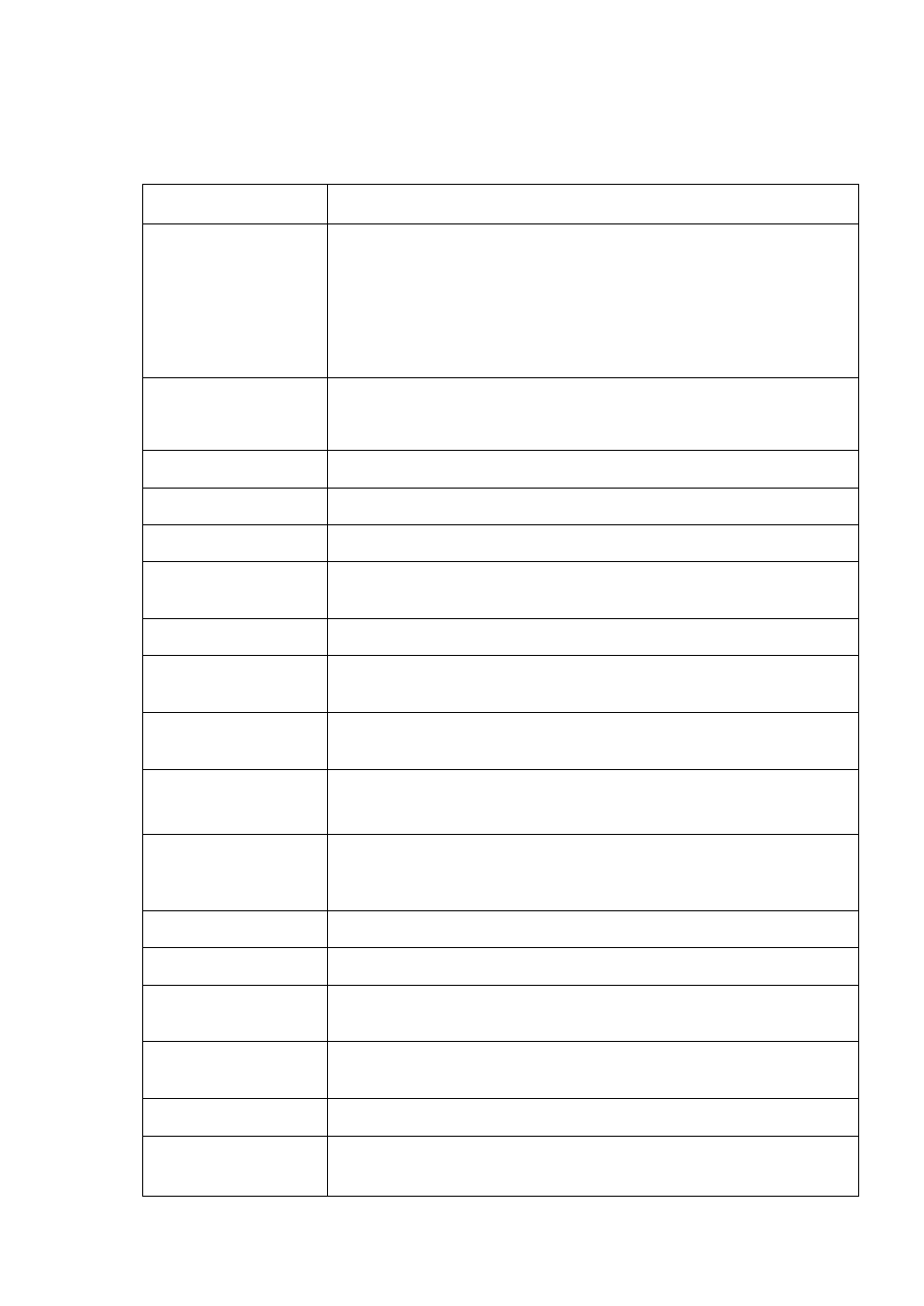

6.0 Technical data

6.1.Technical features

Feature

Specifications

Output range

With Micro-capacity (No 0) dosing screw: 2 pellets - 0.2 kg/hr

With Low-capacity (No 1) dosing screw: 0.1

– 3.5 kg/hr

With Med-capacity (No 2) dosing screw: 0.4

– 10 kg/hr

With High-capacity (No 3) dosing screw: 0.6

– 20 kg/hr

With Extra-capacity (No 4) dosing screw: 1.0

– 35 kg/hr (note1)

(@ 0.7 gr./cm

3

bulk density)

Operation principle

Loss-in-weight dosing

On-line gauge and control of MB/ADD batches

Load cell

15 kg max., temp. compensated

Hopper

3 liter (see note no 2)

Additive loading

Automatic Venturi vacuum loader

Alarm output

N/O dry contact, 24V/30mA max.

Activated at: failure in filling or overdose or calibration error

Driving motor

Maintenance-free, permanent magnet DC motor

Synchronizing with

injection cycle

Dry contact from the injection machine. Feeding period duration

determined either by the injection machine or by the operator

Operation and

setup

Setting of desired MB/ADD % and shot weight

Automatic setup and calibration

Controller

Powerful, sophisticated controller, with alphanumeric display

Communication port (optional)

Data recording

Process data (product weight and required % of MB) and

accumulated data (total injection cycles, total MB consumed and

average percentage %)

Communication

TCP/IP protocol (optional)

Mounting

By neckpiece adapter and quick-release star knobs

Power

230v or 115V +/-10%, 2 A, 200W, 50-60 Hz

Fuse rating: 2A

Installation

category

Over-voltage category 2

Dimensions

See section 3

Weight

22 kg