Sterlco SF1000 Gravimetric Additive Feeder User Manual

Page 27

27

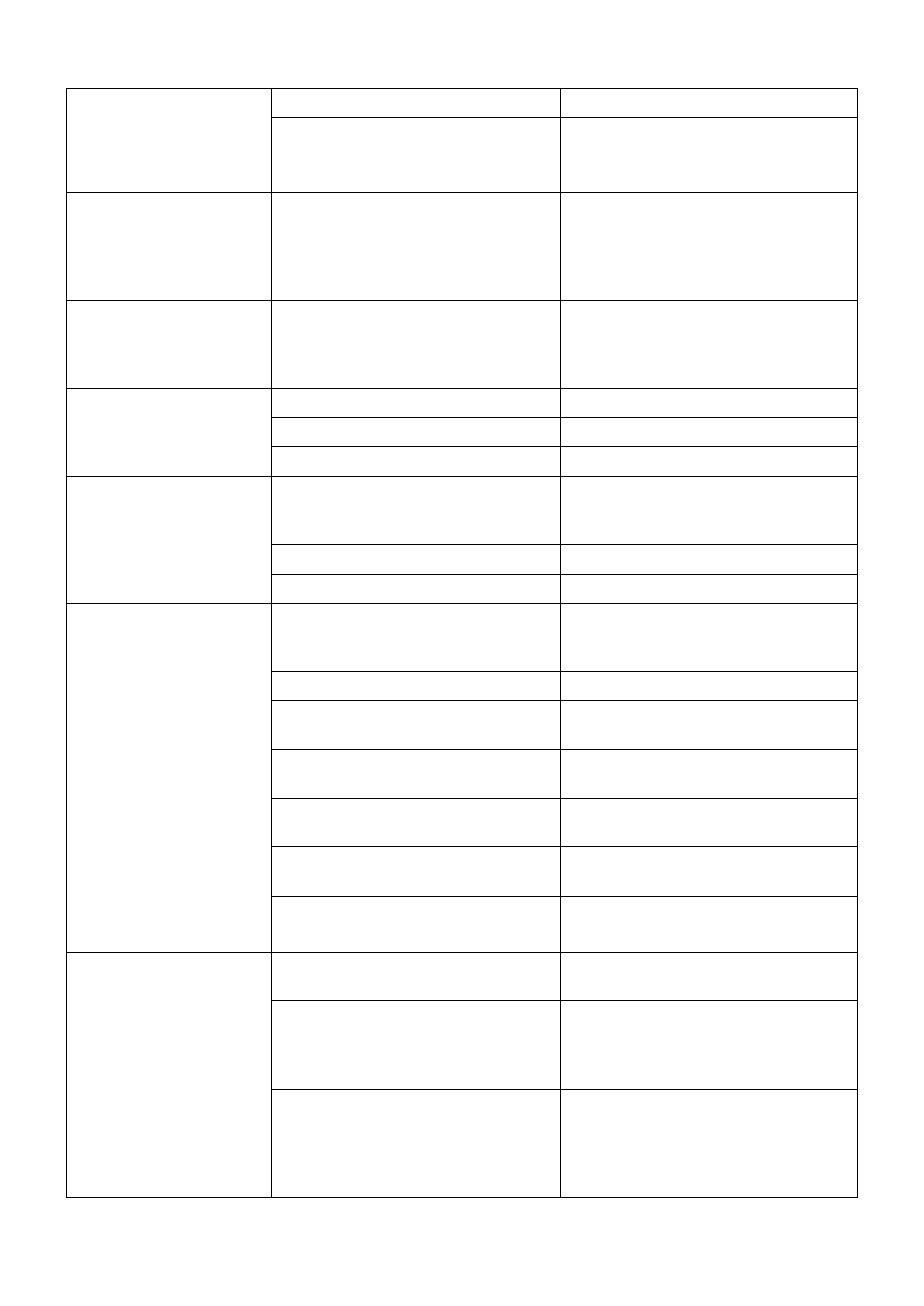

Material container is empty

Refill it

No command order to air valve

Check cable or consult maintenance

dept.

"Overdose" Alarm

Overdose situation (required motor

current is above 100% - its

maximum possible rate)

Check process data (product weight

and required MB %). If data O.K.,

consider replacing dosing screw with

a higher range type

"Overdose" Alarm

Underdose situation (required

motor current is below

5.2% - its

minimum possible rate)

Check process data (product weight

and required MB %) and if O.K.,

consider replacing dosing screw with

a lower range type.

Calibration error

–

"Offset too low"

Load cell is in "Locked" state

Unlock load cell (see App. A)

Load cell is out of order

Replace it

Controller is out of order

Consult Maintenance dept.

Calibration error

– "Gain

too low"

Standard calibration has not been

installed in the hopper, or its value

does not match entered value

Check and enter weight or update

value, if required

Load cell is in "Locked" state

Unlock load cell (see App. A)

Load cell is out of order

Replace it

Motor does not

rotate at first starting, or

during standard

operation

Motor cable is damaged or not

connected

- Check its connection to the

controller, or

- Repair or replace it if required

MB % (“D”) is set to “0"

Correct MB % if required

No rotating command from the

controller

Consult maintenance dept.

Motor or motor's controller is

defective

Consult maintenance dept

The screw is "stuck" by the material Empty hopper, release screw, clean

it and its housing and reinstall it

There is no "Sensor" signal from

the IMM

Consult maintenance dept

Sensor Input is analog (voltage)

instead of "dry contact"

Install a relay to switch from voltage

to dry contact input

No materials dosing,

despite motor rotating

Material blocked at inner weighing

hopper outlet due to some obstacle

Empty hopper and clean it

Material blocked at the outlet of the

inner weighing hopper due to

material bridging

Ask for help - there might be

electrostatic charge or material is too

sticky and can't be used with this

feeder

Material blocked at screw's exhaust

tube and doesn't stream out

-Try to replace the screw with

another type

-Ask for help

— it might be that the

material is too sticky and can't be

used with this feeder