6 trouble shooting – Sterlco SF1000 Gravimetric Additive Feeder User Manual

Page 26

26

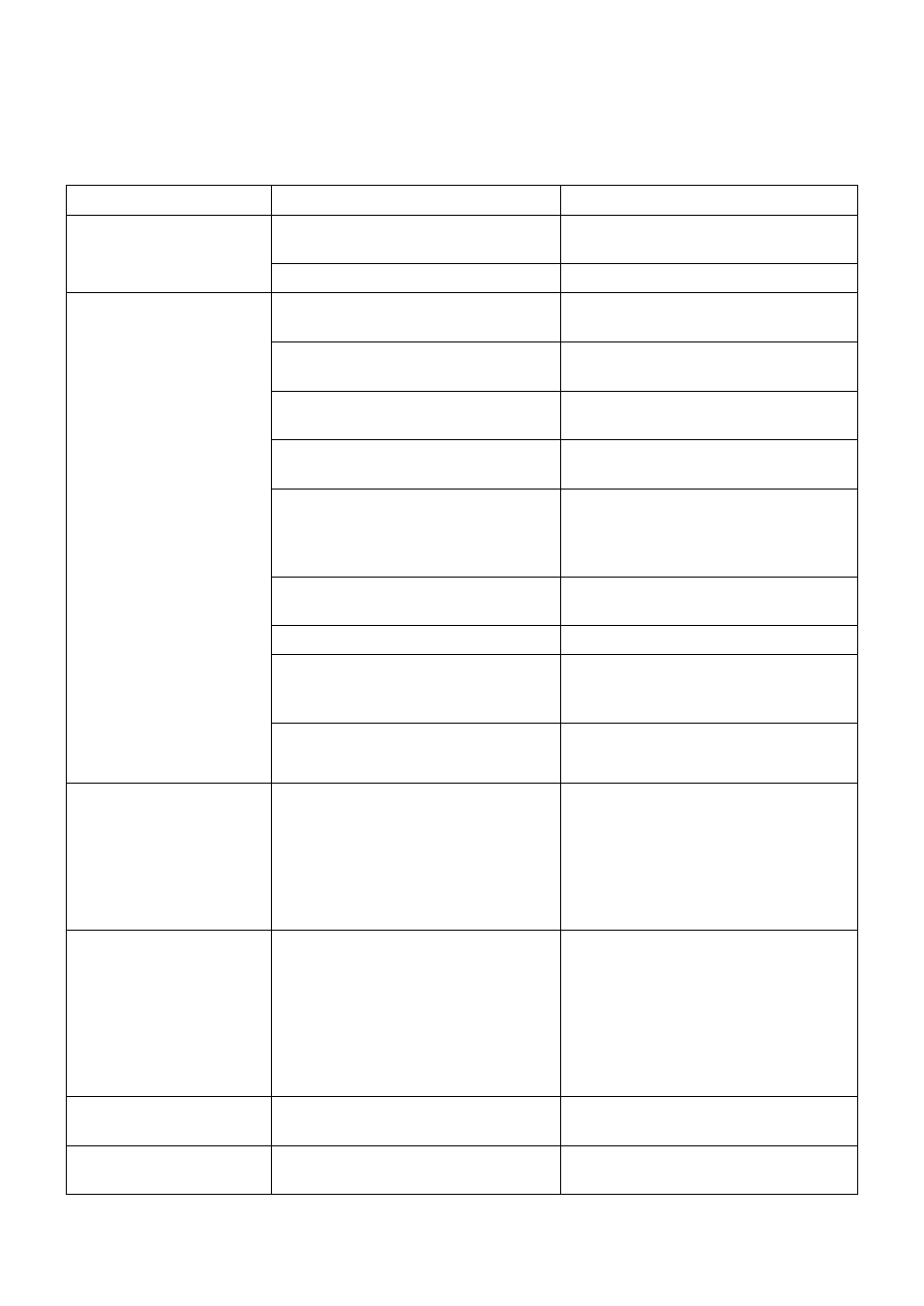

5.6 Trouble shooting

Check the following guide for possible problem causes before contacting service:

Symptom

Possible cause

Correction actions

Controller does not work

Power cord is damaged or

disconnected

-Check cable

-Plug it into the power outlet

Fuse is blown

Replace fuse

No weighing or

unreasonable weighing

results

Load cell is not connected

Connect load cell to its connector in

the controller

Load cell safety catch is still in

"locked" position (see App. A)

Release safety catch to "Unlock"

position (see App. A)

Load cell cable is damaged or not

connected

-Check connection to the controller

-Repair or replace if required

The nuts fixing the load cell to the

weighing hopper are loose

Refasten the nuts

Adjustment of load cell protection

device has been changed, and the

limiter is no longer centered

(clearance is less than 0.5mm)

Readjust the clearance according to

instructions in Appendix A

Static calibration has been changed

for some reason

Repeat calibration procedure

according to Appendix B

Load cell is damaged

Replace it

No free clearance (there is some

obstacle) between internal and

external hoppers

Check for reason and clear it

Controller fault

Consult maintenance dept. or ask for

service

Unreasonable reducing

of motor current

percentage (rpm)

Penetration of vacuum from the

main material hopper loader into the

machine's neck.

This vacuum sucks material from

the Sterling SF-1000 hopper and

thus disrupts the control operation

- Check sealing of the hopper

loader’s emptying valve

- Release undesired vacuum in the

neck by drilling small holes in neck's

sight glass, or by installing small

discs (spacers) on its screws,

creating a narrow releasing slot.

Significant discrepancy

between desired % value

and actual measured

value

The pulse arriving from the injection

machine is not steady; there are

"dips" which the controller interprets

as more than one pulse.

It can be detected by comparing the

value of accumulative cycles in the

Sterling SF-1000 controller to that of

the IMM controller

Try to improve the pulse quality

Too slow convergence to

final desired %

Entered screw type parameter does

not match actual screw in use

Enter Parameters screen, and

replace screw type, if necessary

"No Fill" Alarm

Air valve does not work

Check air supply

Check air valve