Maintenance - gas – Prochem Apex User Manual

Page 38

MAINTENANCE - GAS

APEX 86037630

4-10

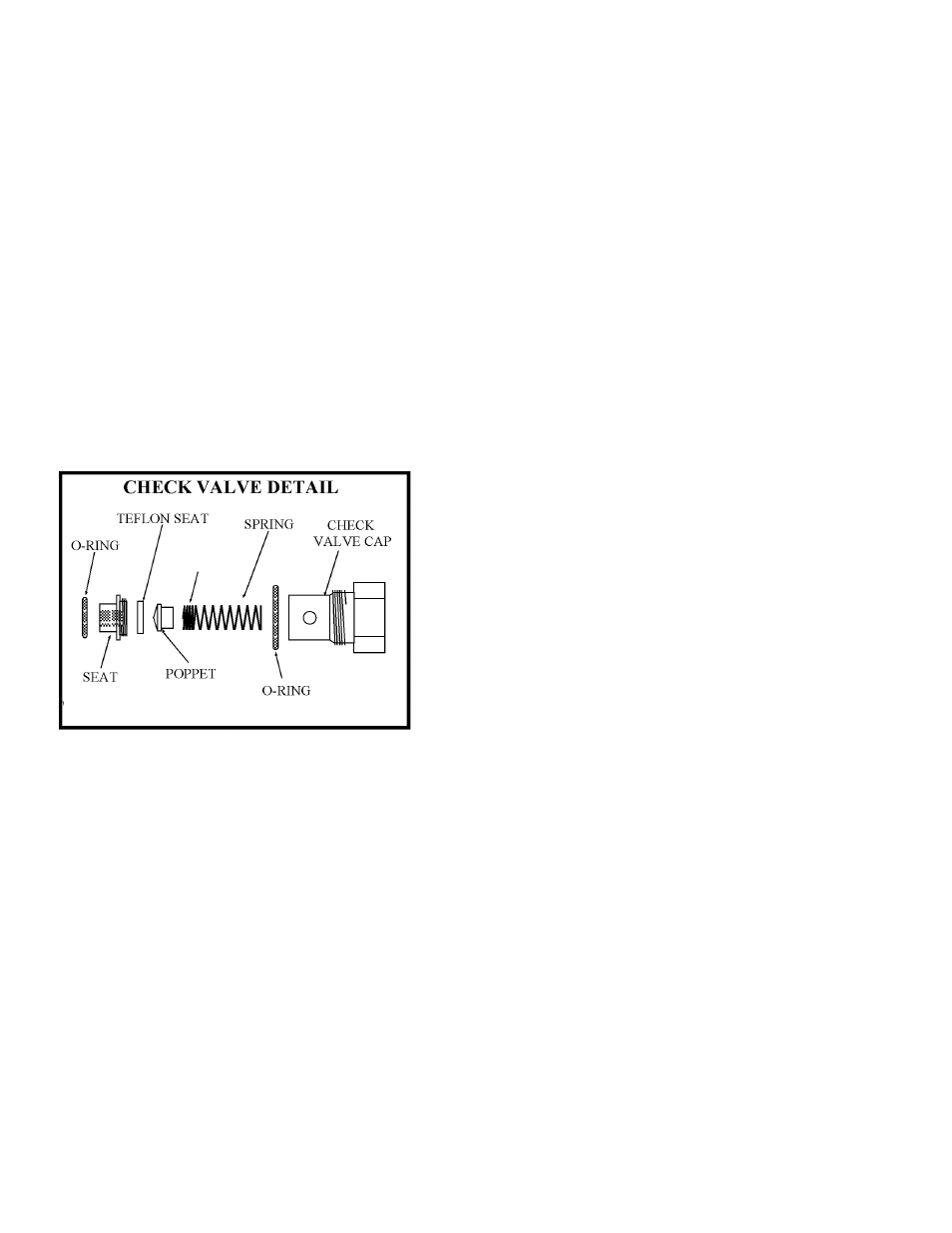

CHECK VALVE (SOLUTION OUTLET)

Inspect the check valve whenever doing service on

the chemical pump or if flow problems occur in the

chemical system:

1. Remove the check valve. Be sure the small o-

ring for the seat comes out with the check valve.

2. Remove the seat, using a 5/16" Allen wrench.

3. Check the Teflon seat for debris or wear. Clean

or replace Teflon seat if needed.

4. Clean the poppet and spring, inspect for wear or

damage, and replace as needed.

5. Re-assemble the check valve. Start the seat by

hand, tighten using a 5/16" Allen wrench. DO

NOT over-tighten seat.

NOTE: Improper seating of the check valve

poppet, damaged spring or o-rings will cause

poor operation of the chemical system.

6. Lubricate the o-rings with o-ring lubricant

Part #86265430 – PRV NO. 05-008035 and

reinstall.

CHEMICAL PUMP

The only repairs which the chemical pump may

require is the replacement of the diaphragm or

check valves. To replace the diaphragm, unscrew

the cover from the body. When replacing the

diaphragm, lubricate the outer edges of the

diaphragm with o-ring lubricant Part # 86265430 –

PRV NO. 05-008035 and reassemble. To replace

the check valves, unscrew the check valve caps.

Replace the check valves and reassemble, using

new o-rings.

DO NOT attempt to re-use o-rings once the check

valves have been removed. See the “Illustrated

Parts Listing” for a parts break-down on the chemical

pump.

8

Use 5/16 Allen

Wrench to remove

Tight wrap

On spring